Datasheets

Download:Pall’s UltiKleen Excellar filter is constructed of the most technologically advanced non-dewetting all-fluoro-polymer media that we offer to the semiconductor industry. This filter is specifically designed to handle the aqueous-based gas-generating chemicals vital for wafer cleaning (SC-1, SC-2, and SPM).

The non-dewetting property of the UltiKleen Excellar filter is achieved using our proprietary MST (Molecular Surface Tailoring) technology to tailor the surface chemistry on a molecular scale. This method is unlike conventional coating-and grafting-based methods that can compromise chemical compatibility and purity. The advantage of MST is that the PTFE membrane remains robust and durable in highly corrosive acids, bases, and organic compounds.

The non-dewetting property of the UltiKleen Excellar filter is achieved using our proprietary MST (Molecular Surface Tailoring) technology to tailor the surface chemistry on a molecular scale. This method is unlike conventional coating-and grafting-based methods that can compromise chemical compatibility and purity. The advantage of MST is that the PTFE membrane remains robust and durable in highly corrosive acids, bases, and organic compounds.

- Non-dewetting PTFE membrane

- Provides increased tool uptime

- All fluoro-polymer construction

- Provided completely prewet

- High temperature and pressure capabilities

- Very high flow rates

- Low differential pressure

- Manufactured in a cleanroom environment

- 100% integrity tested

Materials of Construction

| Components | Materials |

| Filter Medium | Surface-modified PTFE |

| Media Support | PTFE |

| Inner Core / Outer Cage | PFA |

| End Caps | PFA |

| Sealing methods | Melt seal |

| O-ring (for cartridge) | FEP Encapsulated fluoroelastomer |

| Housing (for KC type) | PFA |

Removal Ratings and Operating Conditions

KC (Kleen-Change®) Assembly

| Removal Ratings | 0.05 μm |

| Configurations | T flow, In-line |

| Filter area | 1.2 m2 / 12.9 ft2 |

| Maximum Operating Temperature | 170 ºC / 338 ºF |

| Maximum Operating Pressure | 0.49 MPaG < 25 °C / 71 psig < 77 °F 0.39 MPaG < 60 °C / 57 psig < 140 °F 0.34 MPaG < 90 °C / 49 psig < 194 °F 0.20 MPaG < 120 °C / 29 psig < 248 °F 0.15 MPaG < 150 °C / 22 psig < 302 °F 0.12 MPaG < 170 °C / 17 psig < 338 °F |

Cartridge

| Removal Ratings | 0.05 μm |

| Configurations | ABF1, MRF1 |

| Filter area | ABF1: 1.2 m2 / 12.9 ft2 MRF1: 1.1 m2 / 11.8 ft2 |

| Maximum Operating Temperature | 170 ºC / 338 ºF |

| Maximum Forward differential pressure | 0.59 MPa @ 50 °C / 85 psid @ 120 °F |

UltiKleen™ Excellar Filter

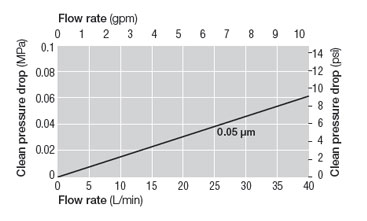

Pressure Drop vs. Liquid Flow Rate (Water 20 ºC )1

1 Typical flow rates. For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Unit conversion: 1 bar = 0.1 MPa

UltiKleen™ Excellar KC Assemblies

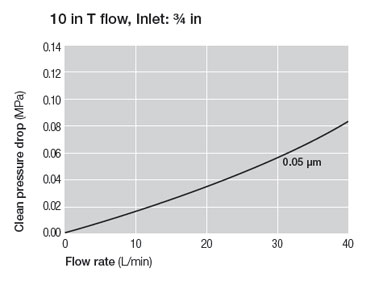

Pressure Drop vs. Liquid Flow Rate (Water 20 ºC )1

1 Typical flow rates. For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Unit conversion: 1 bar = 0.1 MPa

Filter Cartridges

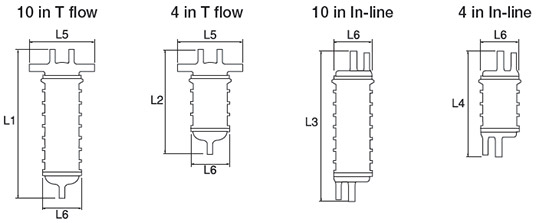

Dimensions

UltiKleen™ Excellar Filter

| Configurations | Nominal Cartridge Length | |

| mm | inch | |

| ABF1 | 286 | 11.2 |

| MRF1 | 264 | 10.4 |

UltiKleen™ Excellar KC Assemblies

| Symbols | Nominal length (mm / in.) |

| L1 | 416 mm / 16.4 in. |

| L2 | 281 mm / 11.1 in. |

| L3 | 430 mm / 16.9 in. |

| L4 | 282 mm / 11.1 in. |

| L5 | 180 mm / 7.1 in. |

| L6 | 106 mm / 4.2 in. |

UltiKleen™ Excellar Filter

ABF1GP [1] 3EH1 [2]

MRF1GP [1] 25EH1 [2]

Table 1

| Code | Removal Ratings |

| D | 0.05 μm |

Table 2

| Code | Prewet Option |

| -K3 | Prewet filter ( packaged in DI water) |

| -K7 | Prewet filter ( packaged in DI water), Low metal extractables2 |

2 Please contact Pall on the extractable conditions

UltiKleen™ Excellar KC Assemblies

LDF [1] [2] GP [3] [4] E [5] [6]

Table 1

| Code | Flow |

| T | T flow |

| N | In-line |

Table 2

| Code | Cartridge Length |

| 05 | 4 inch |

| 1 | 10 inch |

Table 3

| Code | Removal Ratings |

| D | 0.05 μm |

Table 4

| Code | Inlet/Outlet | Vent/Drain | Memo | |

| Head end | Bowl end | |||

| 6 | 3⁄3 in. male | 1⁄4 in. male | 1⁄4 in. male | In-line (5 in. only) |

| 8 | 1⁄2 in. male | 1⁄4 in. male | 1⁄4 in. male | In-line |

| 9 | 1⁄2 in. female | 1⁄2 in. male | 1⁄2 in. female | In-line |

| 12 | 3⁄4 in. male | 1⁄2 in. male | 1⁄2 in. male | T flow |

| 12 | 3⁄4 in. male | 1⁄4 in. male | 1⁄4 in. male | In-line |

| 13 | 3⁄4 in. male | 1⁄2 in. male | 1⁄2 in. male | T flow / In-line |

Table 5

| Code | Connections |

| 0 | Non-connection |

| 1 | 20 series (Flowell) |

| 2 | Super Pillar Type (Nippon Pillar)3 |

| 51 | Flare style |

| 6 | FinalLock4 |

| 71 | Super Pillar 300 P series (Nippon Pillar) |

| 72 | Super Pillar 300 P series L type (Nippon Pillar) |

| 8 | 60 series (Flowell) |

| 9 | 11CR series (Flowell) |

Table 6

| Code | Prewet Option |

| -K3 | Prewet filter ( packaged in DI water) |

| -K7 | Prewet filter ( packaged in DI water), Low metal extractables5 |

3 Pillar is a trademark of Nippon Pillar Packing Co.

4 FinalLock is a trademark of Kurabo Industries Ltd.

5 Please contact Pall on the extractable conditions.

6 Part numbers in conbination with all codes are not always availbale.

Please contact Pall for the part number availability.

We appreciate your review of this product. Please login to your account to leave a review.