Datasheets

Download:The Ultipleat®PC filter is specifically recommended for component parts cleaning applications where high flow rates, together with a 0.1 μm / 0.2 μm particle removal ratings, are required. The PTFE filter membrane is incorporated in a unique, crescent-shaped or laid-over pleat geometry to provide an increase in effective filtration area and service life.

| Features | Benefits |

| Ultipleat construction |

|

| PTFE and polypropylene materials |

|

| No surfactants or binder resins |

|

| Materials of Construction | |

| Filter Membrane | PTFE |

| Support and drainage | Polypropylene |

| Core and cage | Polypropylene |

| End caps | Polypropylene |

| AB style cartridges only | |

| O-ring options | FEP encapsulated fluoroelastomer (standard), ethylene propylene, or fluoroelastomer |

| PUY style cartridges only | |

| Gasket options | Ethylene propylene, fluoroelastomer, polypropylene |

Removal Rating: 0.1 μm , 0.2 μm

Filter area: 0.23 m2 / 2.5 ft2

| Configurations | |

| Nominal length | 254 mm / 10 in. |

| Nominal diameter | AB: 70 mm / 2.75 in, PUY: 64 mm / 2.5 in. |

Operating Conditions1

Maximum operating temperature: 70 ˚C / 158 ˚F

| Maximum differential pressure | Operating Temperature |

| 0.55 MPa / 80 psi | 20 ˚C / 68 ˚F |

| 0.31 MPa / 45 psi | 70 ˚C / 158 ˚F |

1For compatible liquids

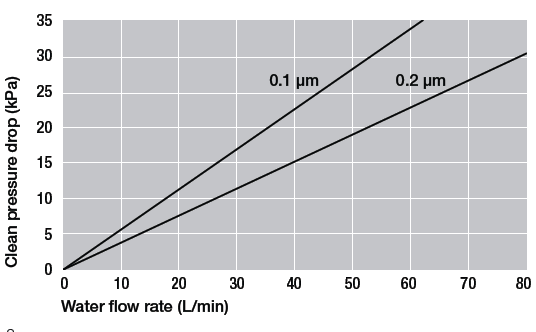

Pressure Drop vs. Liquid Flow Rate (Water, 20°C)2

2 For Liquids with a viscosity differing from water, multiply the pressure drop by the viscosity in centipoises.

Filter Cartridges

Part Numbers / Ordering Information

AB [1] PC [2] [3] [4]

PUY [1] PC [2] [5]

Table 1

| Code | Length (mm / in.) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

Table 2

| Code | Removal Ratings |

| 001 | 0.1 μm |

| 002 | 0.2 μm |

Table 3

| Code | O-ring Size |

| 3 | AS568A - 222 |

| 7 | AS568A - 226 |

Table 4

| Code | O-ring Seal |

| J | Ethylene propylene |

| H | Fluoroelastomer |

| H1 | FEP encapsulated fluoroelastomer3 |

Table 5

| Code | Gasket Seal |

| J | Ethylene propylene |

| H | Fluoroelastomer |

| Y1 | Polypropylene |

3 Standard O-ring for AB style filter cartridge

For availability of specific options and housing details, please contact your Pall Corporation representative

We appreciate your review of this product. Please login to your account to leave a review.