Datasheets

Download:Emflon filter elements are designed for 1.5 nm filtration of bulk gas applications found in the semiconductor industry.

Features

- Wide variety of applications

- High particle retention

- High flow rates vs. differential pressure

- Optimized cartridge design

- Manufactured in a cleanroom environment

- 100% integrity tested

| Components | Materials | |||

| Filter Medium | PTFE | |||

| Media Support | Polypropylene | |||

| Inner Core | Polypropylene | |||

| Outer Cage | Polypropylene | |||

| End Caps | Polypropylene | |||

| O-ring Options | Acid proof fluoroelastomer, FEP Encapsulated fluoroelastiomer |

|||

| Removal Ratings | 1.5 nm | |||

| Filter Areas | AB1 | MCY1001 | MDY1002 | |

| 10" / 254 mm : 9.45 ft2 / 0.88 m2 | 10" / 254 mm : 9.26 ft2 / 0.86 m2 | 20" / 508 mm : 18.52 ft2 / 1.72 m2 | ||

| Nominal Length | 10" / 254 mm 20“ / 508 mm 30" / 762 mm 40“ / 1,016 mm |

20“ / 508 mm 30" / 762 mm |

||

| Diameter | 2.75" / 70 mm | |||

| O-ring Size / End Caps | Code 3 (222 double O-ring / flat end) Code 8 (222 double O-ring / finned end) Code 7 (226 double O-ring bayonet lock / finned end) |

|||

| Maximum Operating Temperature | 194 °F / 90 °C | |||

| Maximum forward differential pressure | 80 psid @ 120 °F / 5.5 bar @ 50 °C 50 psid @ 194 °F / 3.5 bar @ 90 °C |

|||

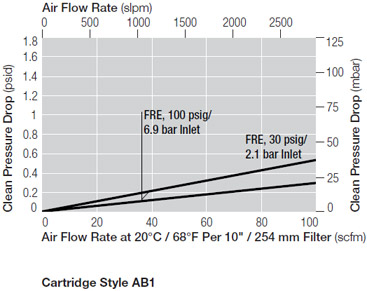

Pressure Drop vs. Gas Flow Rate

Part Numbers / Ordering Information

O-Ring Seal

AB [1] [2] [3] E [4]

| Code | Nominal length (mm / in) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

| 4 | 1,016 / 40 |

Table 2 |

|

| Code | Removal Ratings |

| FR | 1.5 nm |

Table 3 |

|

| Code | O-ring Specifications |

| 7 | AS568A-226 |

| 8 | AS568A-222 |

| 3 | AS568A-222 |

Table 4 |

|

| Code | O-ring Materials1 |

| H1 | FEP Encapsulated Fluoroelastomer |

| HF | Acid-proof Fluoroelastomer |

1Other O-ring material options available.

Gasket seal

MCY1001 [7] E [8]

MDY100 [9] [7] E [8]

| Code | Removal Ratings |

| FR | 1.5 nm |

Table 8 |

|

| Code | Gasket Materials |

| H13 | NBR |

| H2 | PTFE |

| H | Fluoroelastomer |

| J | EPDM |

Table 9 |

|

| Code | Nominal length (mm / in) |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

Representative example part numbers

O-Ring Seal

| AB1FR3EHF | AB2FR8EHF | AB3FR7EHF | AB4FR7EHF |

| AB1FR3EH1 | AB2FR7EHF | AB3FR8EHF | AB4FR3EHF |

| AB1FR7EH1 | AB2FR3EHF | AB3FR3EHF | |

| AB1FR3EHF | AB2FR3EH1 | AB3FR3EH1 | |

| AB2FR7EH1 |

Gasket seal

| MCY1001FREH2 | MDY1002FREH13 | MDY1003FREH13 |

| MCY1001FREJ | MDY1002FREH2 |

We appreciate your review of this product. Please login to your account to leave a review.