Datasheets

Download:A unique combination of Pall's leading edge AresKleen™ purification material combined with Ultramet-L® stainless steel filter media creating the industry's most advanced true point-of-use purifier.

The Gaskleen®ST Purifier assembly is designed to remove contamination from many process gases. Sub ppb level purification is achieved at designed flow rates of up to 5slpm while providing 0.003 μm filtration.

The Gaskleen®ST Purifier assembly is designed to remove contamination from many process gases. Sub ppb level purification is achieved at designed flow rates of up to 5

- Controls and reduces impurities such as O2, H2O, CO2, CO, NMHC, Ni(CO)4 and FE(CO)5

- One-for-one dimensional replacement of conventional in-line particle filter assemblies

- Assembly hardware is made of 316L stainless steel

High efficiency diffusion barrier ensuresintegrity of reactive material during installation- Superior pressure drop characteristics

Wide variety of gases purified- 100% helium leak and pressure tested

- Compact size

- Not orientation sensitive

- Does not generate hazardous waste when used in non-hazardous gas service

- Will not release hydrocarbons

- No detectable metal contribution above background in HCl gas with HCLP material

- No detectable metal contribution above background in HBr gas with HBRP material

Materials

- Electropolished 316 L VAR PLUS stainless steel components

- ≤ 0.25 μm / 10 μin Ra internal surface finish

Particle Removal Efficiency Rating

- 1x109 retention of particles ≥ 0.003 μm up to 5

slpm

Connections

- 1⁄4 in. Gasket Seal, Male/Male (VCR1 compatible)

Operating Conditions

- Maximum Operating Pressure: 2200

psig / 152 bar - Maximum operating temperature:

- 100 °C / 212 °F (INP, SIP, FCP, SF6P)

- 40 °C / 104 °F (GEH4P, OXP, CLXP, HCLP, HBRP, CDAP)

- EU Pressure Equipment Directive: Assemblies have been evaluated and are CE marked per the European Union's Pressure Equipment Directive 2014/68/EU.

Design Flow Rate

- 0-5

slpm @ 15psig / 1 bar - Intermittent flow rates up to 10

slpm can be accommodated with reduced lifetime2

Packaging

- Double bagged

- Outer bag: aluminized mylar3

- Inner bag: polyethylene

- End fittings capped with metal seals

- Product packaged in an argon environment

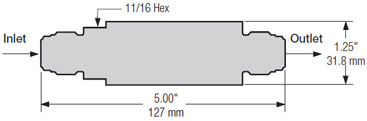

Dimensions

- Length: 5 in. / 127 mm

- Diameter: 11⁄4 in. / 31.8 mm

1 VCR is a trademark of Swagelok Co.

2 Contact the Pall Microelectronics Group for further information.

3 Mylar is a registered trademark of Dupont Teijin Films.

Technical Information

Impurity Removal as Tested in Specific Gases| Specific Gas | Impurity Removal Efficiency |

| Inert Gases: Nitrogen, Argon, Helium, Xenon, Krypton, Neon | < 1 ppb H2O, CO2, O2, and CO as tested in argon and nitrogen using APIMS analyzer |

| Flammable Gases: Silane, Hydrogen, Methane, Ethane, Cyclopropane, Propane, Dimethyl Ether | < 1 ppb H2O, CO2, O2, and CO as tested in argon, nitrogen < 1 ppb H2O as tested in carbon monoxide using trace moisture analyzer H2O and siloxanes removed to trace levels as tested in silane using APIMS |

| Carbon Monoxide | < 1 ppb Ni(CO)4, and < 1 |

| Fluoromethane, Difluoromethane, Trifluoromethane, Tetrafluoroethane, Pentafluoroethane, Heptafluoropropane, Carbon Tetrafluoride, Perfluoropropane, Perfluorocyclobutane, Hexafluoroethane | < 1 ppb H2O, CO2, O2, and CO as tested in argon and nitrogen using APIMS analyzer < 1 < 10 ppb H2O as tested in trifluoromethane using trace moisture analyzer and FTIR |

| Germane | < 1 ppb H2O, CO2, O2, and CO as tested in argon and nitrogen using APIMS analyzer |

| Sulfur Hexafluoride | < 1 ppb H2O, CO2, and O2 as tested in argon using APIMS |

| Oxygenated Gases: Carbon Dioxide, Oxygen, Nitrous Oxide, Clean Dry Air | < 10 ppb H2O < 1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Chlorinated Gases: Boron Trichloride, Chlorine, Trichlorosilane, Dichlorosilane | < 100 ppb H2O < 1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Hydrogen chloride | < 15 ppb H2O as tested in hydrogen chloride using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Hydrogen Bromide | < 50 ppb H2O as tested in hydrogen bromide using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Photolithography clean dry air | < 1 ppb H2O as tested in argon using APIMS analyzer < 300 ppt C4H8 as tested in argon using APIMS Analyzer < 10 ppt SO2 as tested in nitrogen using ion < 15 ppt NH3 as tested in nitrogen using ion < 1 ppt HMDSO as tested in argon using APIMS analyzer and baseline subtraction |

Unit conversion: 1 bar = 100 kilopascals

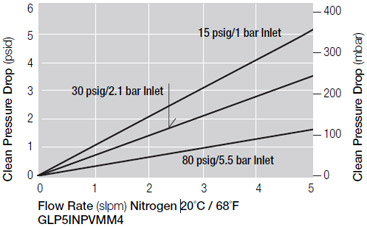

Pressure Drop vs. Gas Flow Rate

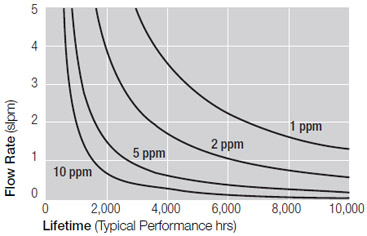

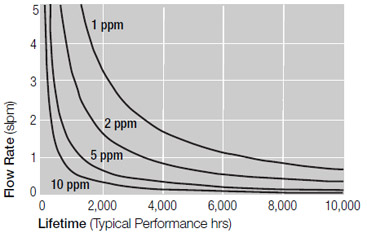

Lifetime Calculations

Pall AresKleen Purification Material: Inert Gas ServiceGaskleen ST Purifier Assembly, Part # GLP5INPVMM4

Inlet Pressure: 30 psig (2.1 bar) Contaminant Challenge as H2O

Pall AresKleen Purification Material: Inert Gas Service

Gaskleen ST Purifier Assembly, Part # GLP5INPVMM4

Inlet Pressure: 30 psig (2.1 bar) Contaminant Challenge as O2

Systems

Dimensions

| Part Number Specifications | Specific Gas | Effluent Purity |

| GLP5INPVMM4 | Inert Gases: Nitrogen, Argon, Helium, Xenon, Krypton, Neon | < 1 ppb H2O, CO2, O2, CO |

| GLP5SIPVMM4 | Flammable Gases: Silane, Hydrogen, Methane, Ethane, Cyclopropane, Propane, Dimethyl Ether | < 1 ppb H2O, CO2, O2, CO |

| Carbon Monoxide | < 1 ppb H2O, O2, CO2, Ni(CO)4, Fe(CO)5 |

|

| GLP5FCPVMM4 | Fluoromethane, Difluoromethane, Trifluoromethane, Tetrafluoroethane, Pentafluoroethane, Heptafluoropropane, Carbon Tetrafluoride, Perfluoropropane, Perfluorocyclobutane, Hexafluoroethane | < 1 ppb H2O, CO2, O2 |

| GLP5GEH4PVMM4 | Germane | < 1 ppb H2O, CO2, O2, CO |

| GLP5SF6PVMM4 | Sulfur Hexafluoride | < 1 ppb H2O, CO2, O2, CO |

| GLP5OXPVMM4 | Oxygenated Gases: Carbon Dioxide, Oxygen, Nitrous Oxide | < 10 ppb H2O |

| GLP5CLXPVMM4 | Chlorinated Gases: Boron Trichloride, Chlorine, Trichlorosilane, Dichlorosilane | < 100 ppb H2O |

| GLP5HCLPVMM4 | Hydrogen Chloride | < 15 ppb H2O |

| GLP5HBRPVMM4 | Hydrogen Bromide | < 50 ppb H2O |

| GLP5CDAPVMM4 | Photolithography clean dry air | < 1 ppb H2O, < 300 ppt organics (as C4), < 10 ppt acid gases (as SO2), < 15 ppt basic gases (as NH3), < 1 ppt refractory compounds (as HMDSO) |

*Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.