Datasheets

Download:Service Instructions

Download:High-performance degas technology to enhance industrial ink jet printer performance

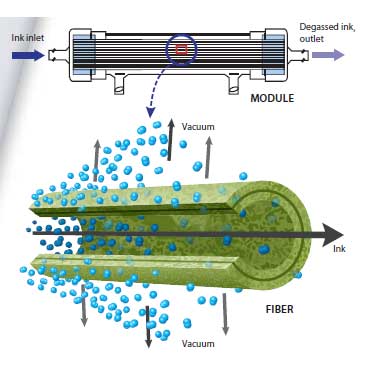

The UltiFuzor™ degas module from Pall is a compact and economical point-of-use hollow fiber contactor with a large membrane area. The UltiFuzor module is intended for use in a wide range of industrial ink jet printers to remove dissolved gasses, prevent bubble formation and assure printer performance.

The module features a lumenside or interior fiber ink flow path and unique tri-layer hollow fiber technology, enabling high degas efficiency performance. The module incorporates a black housing for UV sensitive inks and easy-to-use female luer lock compatible connections.

Lumenside Ink Flow Path

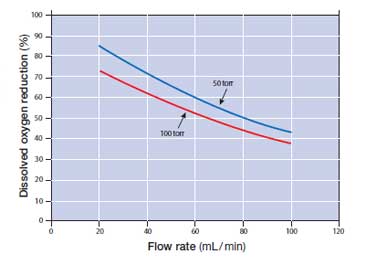

Passing the ink through the interior of the hollow fibers allows for sequential gas diffusion along the length of these fibers, from the inlet to the outlet of the module. This continuous ink degassing process is very effective for removing dissolved gases to very low levels. The extent of degassing can be controlled by regulating the vacuum level. Other factors, such as flow rate and temperature, will also affect the amount of dissolved gas removal.

The unique module design allows for a very large, effective membrane area due to high fiber packing density. As a result, the module can be used at relatively high flow rates and still achieve excellent dissolved gas levels.

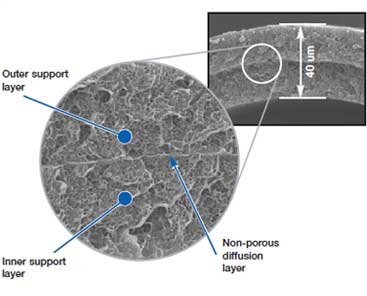

Multi-Layer Hollow Fiber Membrane Technology

The UltiFuzor degas fiber has a thin, non-porous polyethylene membrane sandwiched between two protective, highly porous, polyethylene layers, as indicated in the photomicrograph to the left. The gas diffuses rapidly across the very thin middle layer, whereas its non-porous structure prevents even low surface tension inks from leaking into the vacuum line. The inner layer protects the fiber from being damaged by abrasive pigments and thus enhances on-stream life.

Materials of Construction

| Housing | Polypropylene with black colorant |

| Fiber | Polyethylene |

| Potting compound | Epoxy Resin |

Operating Conditions*

| Maximum Operating Pressure | 0.2 MPa @ 45 °C 30 psig @ 113 °F |

| Maximum Operating Temperature |

45 °C / 113 °F |

* Fluids that do not soften, swell or adversely affect the module, fiber or potting compound.

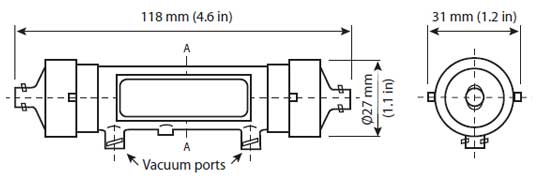

Dimensional Drawing

*Note - Service Instructions can be downloaded from the "Download Datasheet" dropdown above.

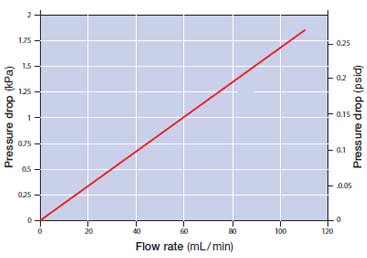

Typical Flow Rate vs Differential Pressure (1)

Typical Dissolved Oxygen Reduction vs Flow and Vacuum Level in Water

(1) For fluids of 1 cP viscosity. As a general guide, for other viscosities, multiply differential pressure by viscosity in cP.

Ordering Information

(This is a guide to the part numbering structure only. For availability of specific options, please contact Pall)

Pall Part Number = UDM-21110

UltiFuzor Degas Module for Digital Printing with female luer lock compatible connections. Modules are individually bagged and bulk packaged 25 per carton with 4 cartons per case.

Below is our other series

We appreciate your review of this product. Please login to your account to leave a review.