Datasheets

Download:Compact, Self-Contained Filter Assemblies

for Use in Digital Printing Systems

The Pall® Small Capsule Filter (SCF) is a compact filter assembly designed for the needs of equipment OEMs where fine filtration and low hold-up volumes are critical.This capsule features a high-area pleated filter construction for long service life and low initial pressure drop, ideal for situations where space is at a premium. In addition to the standard polypropylene capsule, an opaque UV resistant capsule in polypropylene is also available.

Features

- The SCF assemblies are absolute-rated filter capsules for ink jet ink filtration on Digital Printing systems.

- No binders, adhesives or mold release agents are employed in the manufacture of this product.

- The SCF assemblies feature Pall HDC® II polypropylene filter media. (Reference USD1295 literature for further details). Other media options are available upon request.

- The inlet and outlet connections are heavyduty female luer lock connectors.

| Features | Advantages | Benefits |

|

|

|

| Materials of Construction | |

| Filter Media | Melt-blown polypropylene |

| Shell | UL-recognised polypropylene |

| Core, Cage and Endcaps | Polypropylene |

| Operating Conditions | |

| Maximum Operating Pressure | 60 psig @ 32-120 °F 4 barg @ 0-50 °C |

| Maximum Differential Pressure | 40 psid 2.75 bard |

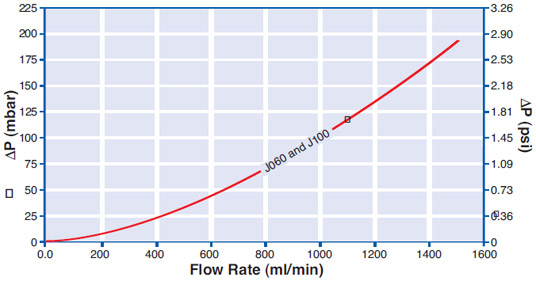

Typical Flow Rate versus Differential Pressure 1

1 For fluids of 1 cP viscosity. As a general guide, for other viscosities, multiply differential pressure by viscosity in cP.

Filter Capsules

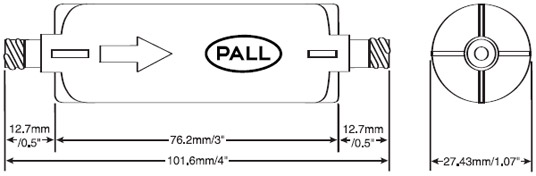

Dimensional Drawing

This is a guide to the part numbering structure only. For availability of specific options, please contact Pall.

S C F 3 1 1 [Table 1 Code] [Table 2 Code]

S C F 3 1 1 [Table 1 Code] [Table 2 Code]

Table 1

| Code | Capsule |

| 1 | Standard |

| 2 | UV resistant (black) |

Table 2

| Code | Removal Rating* |

| J060 | 6 μm |

| J100 | 10 μm |

* Based on the modified OSU-F2 test in water

We appreciate your review of this product. Please login to your account to leave a review.