Datasheets

Download:Service Instructions

Download:Next Generation Capsule Filter Designed to Ensure Critical Protection of Ink Jet Printheads and Optimum Digital Printer Performance

The Multiple Application Capsule (MAC) is a self-contained filter assembly designed to meet the ever increasing needs of the digital ink jet printer. This unique capsule will provide a high level of printhead protection and long service life in ink jet applications. Both the standard and UV-resistant MAC filter assemblies offer flexibility in filter media and connector options that allow for easy customization of the product.Correct media selection can impact filter performance characteristics such as pressure loss, gel retention and service life. The MAC filter offers four high-efficiency (ß-5000 rated) Pall media to meet your digital printing filtration goals: HDC® II, pleated Profile® Star, Profile® II and Ultipor® GF Plus media.

Features

- Compact Filter Capsule with Ink-Jet-Specific Features

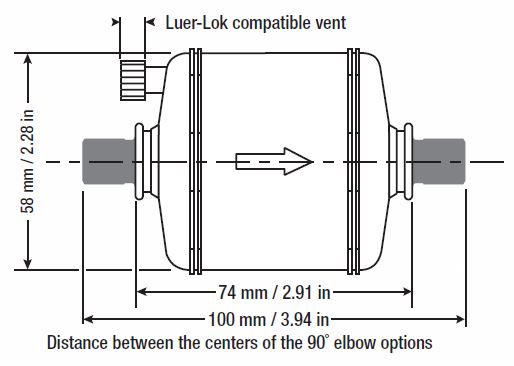

The MAC filter is designed to meet the digital printing OEM's needs with several key features: a compact form to minimize internal ink volume and waste, an optional UV-resistant housing to prevent ink curing, and an anti-roll design to reduce ink spillage. - Dual-Filtration Design

The MAC filter with pleated media features an integral high-performance last chance filter for the assurance of maximum cleanliness without a sacrifice in pressure loss. - Robust Design and Construction

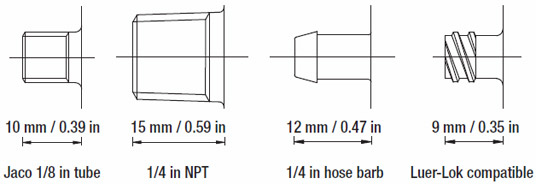

The MAC filter features a robust, thick-wall construction with integrally molded connectors to serve the needs of OEMs using solvent-based inks. This premium construction, in combination with highcapacity filter media will yield a long service life. - User-Friendly Connector Options

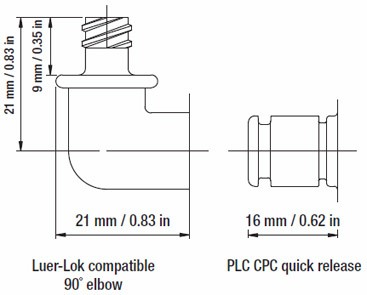

A wide range of connector options are available on the MAC filter. For fast, clean filter changes, CPC* quick-release and standard Luer-Lok* compatible connections are available. In systems that use rigid tubing, two available sizes of Jaco* fittings are ideal compression fitting options. In addition, other standard connection types are available, such as NPT and hose barb. - All-Polymeric Capsule Construction

UL-Recognized Housing Material - The standard MAC filter housing components are manufactured using a polypropylene with a UL94HB classification.

UV-Resistant Housing Material - The UVresistant MAC filter housing contains an additional carbon black filler for protection from UV light.

| Features | Advantages | Benefits |

| Dual filtration capability | Can be used as part of a Total Cleanliness program | Maximum printhead protection |

| Choice of filter media options | Optimized ink filtration | Consistent, reliable printing performance |

| Opaque capsule option | Offers protection from UV light | Prevents curing of the UV fluids during filtration |

| No binders, glues or mould release agents are employed | Low extractables | Good chemical compatibility and economical disposal |

| Anti-roll design and quick release connections | Reduces ink spillage | Quick and easy filter changeouts |

* CPC is a trademark of Colder Products Company; Luer-Lok is a trademark of Becton, Dickinson, and Company; Jaco is a trademark of Jaco Manufacturing Company; UL is a trademark of Underwriters Laboratories Inc.

| Materials of Construction | |

| Filter media | Polypropylene (Profile II, Profile Star, HDC II) Resin-bonded microfiber on polyester subtrate (Ultipor GF Plus media) |

| Core, housing and endcaps | Polypropylene / Polyethylene |

| Standard housing | Polypropylene (UL 94HB Classification) |

| Operating Conditions1 | |

| Maximum allowable pressure | 6.5 barg / 94 psig |

| Maximum allowable temperature | 50 °C / 122 °F |

1 Fluids that do not soften, swell or adversely affect the filter or materials of construction.

Differential Pressure Calculation

The estimated differential pressure (ΔP) for any MAC filter can be calculated using the following formula:ΔP (psid) = ([flow (lpm)]2 x Factor 'A') + ([flow (lpm)] x Factor 'B' x viscosity [cps])

ΔP (mbar) = ΔP (psid) x 68.9

| Connector Code | Housing Factor A |

| 1 | 0.16 |

| 1R | 0.50 |

| 2 | 1.61 |

| 3 | 0.05 |

| 5 | 0.23 |

| 7 | 1.20 |

| 7R | 1.90 |

| 8 | 0.13 |

| Media Grade | Cartridge Factor B |

| A015 | 0.98 |

| A030 | 0.67 |

| A050 | 0.35 |

| A100 | 0.19 |

| J012 | 0.89 |

| J025 | 0.39 |

| J045 | 0.25 |

| J060 | 0.09 |

| Y050 | 0.89 |

| Y100 | 0.25 |

| Y200 | 0.09 |

Filter Capsules

Filter Media Options

| Profile II Media | Profile Star Media |

|

|

| HDC II Media | Ultipor GF Plus Media |

|

|

Dimensional Drawing – Standard Configuration

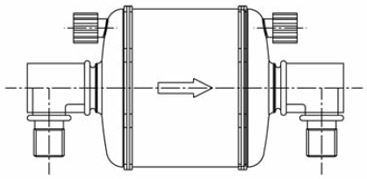

Sample Drawing with Dual Vent Option

Sample Drawing with No Vent Option

The Multiple Application Capsule is Available with the Following Connector Configurations.

Ordering Information / Part Numbers2

M A C [1] [2] [3] [4] [5]| Code 1 | |

| W | Standard |

| C | UV resistant (black) |

| Code 2 | Removal Rating3 |

| Profile Star Media | |

| A010 | 1 μm |

| A015 | 1.5 μm |

| A030 | 3 μm |

| A050 | 5 μm |

| A100 | 10 μm |

| A200 | 20 μm |

| A400 | 40 μm |

| Profile II Media | |

| Y005 | 0.5 μm |

| Y010 | 1 μm |

| Y030 | 3 μm |

| Y050 | 5 μm |

| Y100 | 10 μm |

| HDC II Media | |

| J006 | 0.6 μm |

| J012 | 1.2 μm |

| J025 | 2.5 μm |

| J045 | 4.5 μm |

| J060 | 6 μm |

| J100 | 10 μm |

| Ultipor GF Plus Media | |

| U030Z | 3 μm |

| Code 3 | Connector |

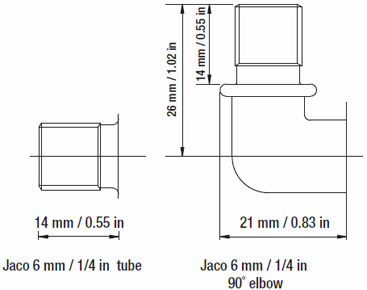

| 1 | Jaco 6mm / 1⁄4 in. tube |

| 1R | Jaco 6mm / 1⁄4 in. tube, 90° elbow |

| 2 | Jaco 1⁄8 in. tube |

| 3 | 1⁄4 in. NPT |

| 5 | 1⁄4 in. hose barb |

| 7 | Luer-Lok compatible |

| 7R | Luer-Lok compatible, 90° elbow |

| 8 | 1⁄4 in. CPC quick release (PLC 12 series) |

| Code 4 | Seal Option4 |

| J | EPR |

| Code 5 | Vent Option |

| None | Single vent (standard) |

| D | Dual vent |

| N | No vent |

2 This is a guide to the part numbering structure only. For availability of specific options, please contact your local Pall representative.

3 Based on the modified OSU-F2 test in water.

4 Only required for Code 8 connector option.

We appreciate your review of this product. Please login to your account to leave a review.