Datasheets

Download:The Pall UltiKleen STG filter is specifically designed for the filtration of organic stripper in non-ashing polymer stripping applications, where the large gel count is high.

The large size of these gels can rapidly plug conventional membrane filters leading to short filter life and process downtime.

The UltiKleen STG filter uses a highly engineered multilayer media construction that combines high gel retention capacity layers with an optimized pleat design for maintaining continuous fluid flow.

The result is superior gel removal and long filter life for extended process operation.

The large size of these gels can rapidly plug conventional membrane filters leading to short filter life and process downtime.

The UltiKleen STG filter uses a highly engineered multilayer media construction that combines high gel retention capacity layers with an optimized pleat design for maintaining continuous fluid flow.

The result is superior gel removal and long filter life for extended process operation.

- Maximum Gel Removal

- Improved Flow

- Multilayer Media Design

- All fluoro-polymer construction

- 100% integrity tested

- Prefilter and Final filter grades

Materials

- Filter Media: PTFE

- Media Support: PTFE, PFA

- Cage, core, and end caps: High purity PFA

- O-ring option: FEP encapsulated fluoroelastomer, Perfrez1 PXC-Ultra

Removal Ratings

- 50 μm, 10 μm, 0.2 μm, 0.1 μm

Filter Areas

- 254 mm / 10 in. (ABF1): 0.48 m2 / 5.2 ft2

- 254 mm / 10 in. (ABFG1): 0.5 m2 / 5.4 ft2

Configurations

Diameter:- ABF: 70 mm / 2.75 in.

- ABFG: 83 mm / 3.27 in.

- 254 mm / 10 in.

- Code 3 (222 double O-ring / flat end)

Operating Conditions

Maximum Operating Temperature:- 170 °C / 338 °F

- 4.2 kg/cm2 @ 110 °C / 60 psid @ 230 °F

- 3.5 kg/cm2 @ 20 °C / 50 psid @ 68 °F

1 Perfrez PXC-Ultra is a trademark of Applied Seals North Americas

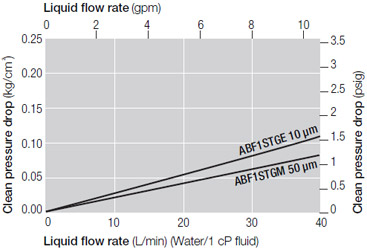

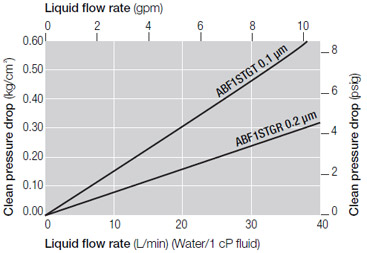

Pressure Drop vs. Liquid Flow Rate2

2 Typical flow rates. For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

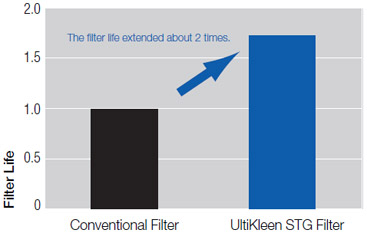

Field Test Results of UltiKleen STG Filter vs Conventional Filter

The graph shows the results of tests conducted at one of Japan's largest semiconductor manufacturer's and the increase of filter life with the Ultikleen STG filter vs. a conventional design fluoro-polymer membrane filter.

Filter Capsules

| Part Number3 | Removal |

Length |

Configuration Code |

O-Ring Material4 |

| ABFG1STGM3EH38-K3 | 50 | 254 / 10 | 3 | Perfrez PXC-Ultra |

| ABFG1STGM3EH1 | 50 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

| ABFG1STGE3EH1-K3 | 10 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

| ABF1STGR3EH1 | 0.2 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

| ABF1STGR3EH1-K3 | 0.2 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

| ABF1STGT3EH1 | 0.1 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

| ABF1STGT3EH1-K3 | 0.1 | 254 / 10 | 3 | FEP Encapsulated fluoroelastomer |

3 "K3" at end of part number added for prewet option.

Unit Conversion: 1 kg/cm2 = 0.98 bar

We appreciate your review of this product. Please login to your account to leave a review.