Datasheets

Download:Gas diffusers are ideally suited for vent applications on load lock interfaces or other vacuum chambers where large volumes of gas are flowing in a short amount of time. The Pall ChamberKleen™ 1100 and 5500 Series diffusers combine a stainless steel filter and a unique diffuser membrane that allows flow in 360 degrees. This combination allows large volumes of gas to flow in a uniform manner, limiting the disturbance of particles in the chamber. Consequently, fast vent times can be achieved with little particle disturbance.

- Reduces turbulent gas flow during venting of process chambers

- 360° diffuser design optimizes gas flow

- 316L stainless steel filter medium

- 316L stainless steel diffuser

- Cleanroom manufactured and packaged

Materials

- 316L stainless steel filter medium

- 316L stainless steel diffuser

- Viton1 O-ring

- ≤ 22 μin / 0.56 μm Ra internal surface finish

Removal Rating

- ≥ 0.003 μm

- No particle contribution above background; ≤ 1 particle /(ft3 or m3)

Connections

- 1100 Series: NW25 ISO Vacuum Flange

- 5500 Series: NW63 ISO Vacuum Flange

Operating Conditions

- Design Flow Rate2

- 1100 Series: 15 slpm @ 15 psig / 1 bar inlet and outlet to full vacuum (<10 torr)

- 5500 Series: 150 slpm @ 15 psig / 1 bar inlet and outlet to full vacuum (<10 torr)

- Maximum Operating Temperature

- 1100, 5500 Series: 300°F / 149°C (limited by O-ring flange connection)

Recommended Applications

- Vacuum chamber

- Load lock chamber

1 Viton is a registered trademark of DuPont Dow Elastomers

2 Additional designs are available. Please contact Pall Microelectronics for more information.

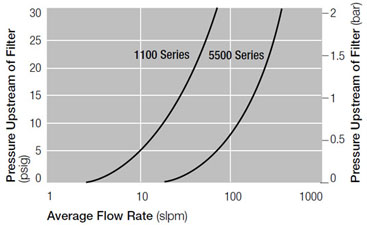

Pressure vs. Average Flow Rate

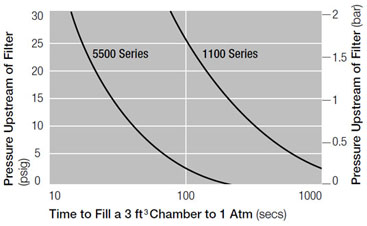

Pressure vs. Chamber Fill Time

Filter Capsules

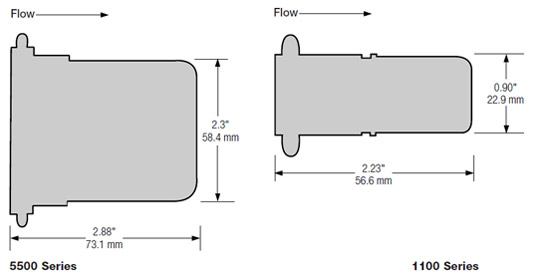

Dimensions

| Part Number | Description | Design Flow Rate3 (slpm) |

| CK1100I25H | 1100 Series, 316L stainless steel filter, Viton1 O-ring | 0-15 |

| CK5500I63H | 5500 Series, 316L stainless steel filter, Viton O-ring | 0-150 |

3 Reference Design Flow Rate on page 182 of catalog.

Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.