Datasheets

Download:The UltiKleen G3 Excellar ER filter combines enhanced retention (ER) and improved non-dewetting properties to enable semiconductor makers to meet the critical chemical process filtration requirements beyond the 45 nm manufacturing node.

The UltiKleen G3 Excellar ER filter media is made using Pall's proprietary Molecular Surface Tailoring (MST) technology. The advanced PTFE membrane has a hyperfine pore matrix design that provides a significant improvement in the retention of deep sub-micron size particles. Designed for critical single-pass point-of-use retention requirements, the UltiKleen G3 Excellar ER filter demonstrates a high flow rate that makes it suitable for recirculation bath applications.

Pall's non-chemical additive MST process increases the UltiKleen G3 Excellar ER filter's wettability in aqueous chemicals including SPM, SC-1 and SC-2. Pall's advanced ultra low extractables Me-KleenSM K7 post-treatment process is also available to reduce metal ion extractables to a low single digit ppb total.

The UltiKleen G3 KC assembly has a slightly larger diameter while maintaining the same face-to-face sealing distance as the UltiKleen G2 KC (T– flow) assembly. The increased diameter accommodates a larger format UltiKleen Excellar ER filter with significantly increased filter area for increased flow rates and longer service life.

The UltiKleen G3 Excellar ER filter media is made using Pall's proprietary Molecular Surface Tailoring (MST) technology. The advanced PTFE membrane has a hyperfine pore matrix design that provides a significant improvement in the retention of deep sub-micron size particles. Designed for critical single-pass point-of-use retention requirements, the UltiKleen G3 Excellar ER filter demonstrates a high flow rate that makes it suitable for recirculation bath applications.

Pall's non-chemical additive MST process increases the UltiKleen G3 Excellar ER filter's wettability in aqueous chemicals including SPM, SC-1 and SC-2. Pall's advanced ultra low extractables Me-KleenSM K7 post-treatment process is also available to reduce metal ion extractables to a low single digit ppb total.

The UltiKleen G3 KC assembly has a slightly larger diameter while maintaining the same face-to-face sealing distance as the UltiKleen G2 KC (T– flow) assembly. The increased diameter accommodates a larger format UltiKleen Excellar ER filter with significantly increased filter area for increased flow rates and longer service life.

Features

- Enhanced retention (ER) of particles

- Hyperfine PTFE media matrix design

- Increased filer area of 4.4 m2/47.4 ft2

- High flow rates

- All ultra high purity fluoro-polymer construction

- Low extractables (Me-Kleen option is available)

- Provided fully prewet with ultrapure water as standard

- Downstream core vent reduces potential for bubble collection and premature blockage

Materials of Construction

| Filter medium: | Surface modified PTFE |

| Media support: | PFA |

| Inner core: | PFA |

| Outer cage: | PFA |

| End caps: | PFA |

| Housing: | PFA |

| Removal Rating | 20 nm |

| Configurations | T-flow, In-line |

| Nominal Filter Area | 4.4 m2 / 47.4 ft2 |

| Maximum Operating Temperature | 185 °C / 365 °F |

| Maximum Operating Pressure | 0.49 MPaG (71 psig) @ 25 ºC (77 ºF) 0.39 MPaG (57 psig) @ 60 ºC (140 ºF) 0.34 MPaG (49 psig) @ 90 ºC (194 ºF) 0.20 MPaG (29 psig) @ 120 ºC (248 ºF) 0.15 MPaG (22 psig) @ 150 ºC (302 ºF) 0.12 MPaG (17 psig) @ 185 ºC (365 ºF) |

Dimensions

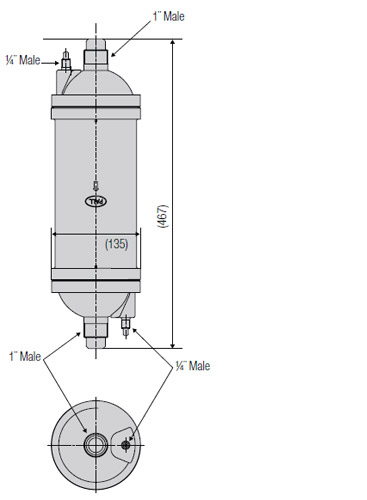

1 inch In-Line

Flare Style

LDFHN1GPK164E51

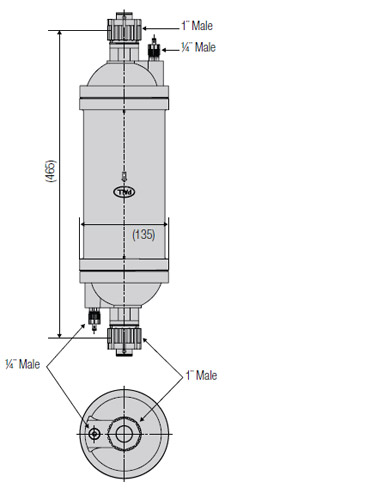

1 inch In-Line

Super Pillar 300P Series

LDFHN1GPK164E71

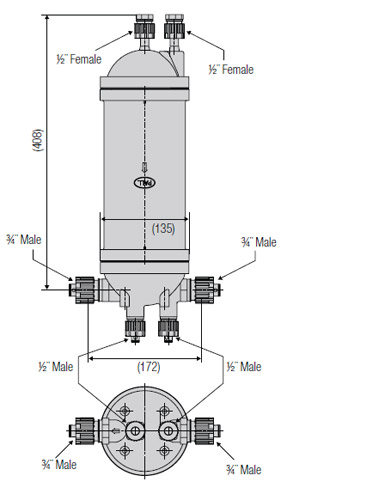

3⁄4 inch T-Flow

Super Pillar 300P Series

LDFHT1GPK12E71/72

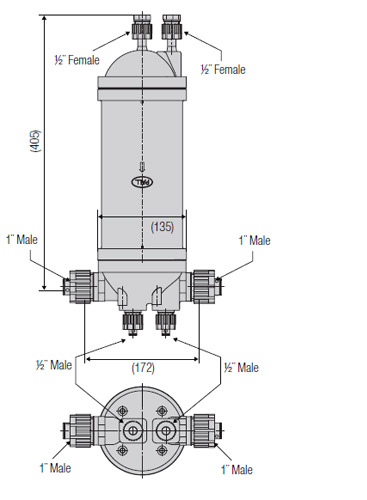

1 inch T-Flow

Super Pillar 300P Series

LDFHT1GPK16E71/72

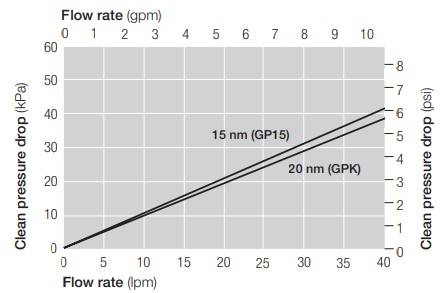

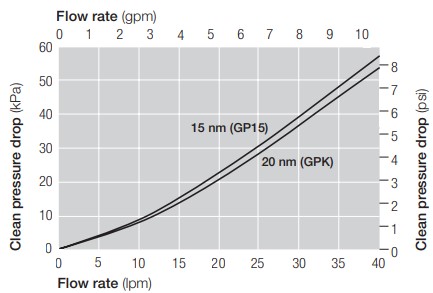

Pressure Drop vs. Liquid Flow Rate

1 inch T-flow, In-line

3⁄4 inch T-flow

Filter Capsules

Pall Part Number = LDFH [1] 1GP [2] [3] E [4] [5]

1 Disposable capsules are not available with every option. Please contact Pall for the part number availability.

Table 1

| Code | Flow |

| T | T-flow |

| N | In-line |

Table 2

| Code | Removal Rating |

| 15 | 15 nm |

| K | 20 nm |

Table 31

| Code | Inlet/outlet | Vent/drain | Memo | |

| Head end | Bowl end | |||

| 12 | 3⁄4 in. male | 1⁄2 in. male | 1⁄2 in. female | T-flow |

| 128 | 3⁄4 in. male | 1⁄2 in. male | 1⁄2 in. male | T-flow |

| 16 | 1 in. male | 1⁄2 in. male | 1⁄2 in. female | T-flow |

| 164 | 1 in. male | 1⁄4 in. male | 1⁄4 in. male | In-line |

| 168 | 1 in. male | 1⁄2 in. male | 1⁄2 in. male | T-flow |

Table 4

| Code | Connections |

| 2 | Super Pillar Type (Nippon Pillar)2 |

| 51 | Flare style |

| 71 | Super Pillar 300 P Series (Nippon Pillar) |

| 72 | Super Pillar 300 P Series L Type (Nippon Pillar) |

Table 5

| Code | Prewet option |

| -K3 | Prewet filter (packaged in DI water) |

| -K7 | Prewet filter (packaged in DI water), low metal extractables3 |

1 Disposable capsules are not available with every option. Please contact Pall for the part number availability.

2 Pillar is a trademark of Nippon Pillar Packing Co.

3 Please contact Pall for the extractable conditions.

We appreciate your review of this product. Please login to your account to leave a review.