Datasheets

Download:The UltiKleen JKC (Junior Kleen-Change®) assembly is a completely disposable filter unit consisiting of all fluoro-polymer components.

Features and Benefits

- Capsule assembly incorporates cartridge and housing

- High mechanical pressure rating

- Low differential pressure

- Low extractables

- Compatible with virtually all chemicals

- 100% integrity tested

- O-ring not required

- Ultipleat® filter cartridge ensures excellent effluent cleanliness

- In-line configuration available

Materials of Construction

| Components | Materials |

| Filter Medium | PTFE |

| Media Support | PTFE / PFA |

| Core / Outer Cage | PFA |

| End Caps | PFA |

| Housing | PFA |

Removal Ratings and Operating Conditions

| Removal Ratings | 0.2 μm, 0.1 μm, 0.05 μm |

| Configurations | In-line |

| Nominal Filter Area | 1300 cm2 / 1.4 ft2 |

| Maximum Operating Temperature | 120 ˚C / 248 ˚F |

| Maximum Operating Pressure | 0.50 MPaG < 25 deg C / 73 psig < 77 deg F 0.20 MPaG < 90 ˚C / 28 psig < 194 ˚F 0.15 MPaG < 120 ˚C / 21 psig < 248 ˚F |

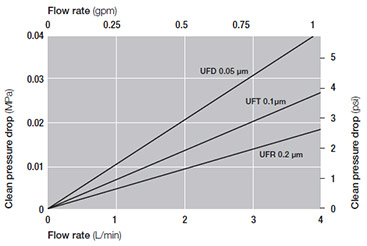

Pressure Drop vs. Liquid flow Rate1 (Water, 20 °C)

1 Typical flowrates. For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Unit conversion: 1 bar = 0.1 MPa

Filter Capsules

Operating Recommendations

- Prewet option is available. If prewet is not selected, proper wetting procedures should be followed. IPA or other low-surface-tension wetting liquids need to be completely flushed before chemical contact.

- Proper venting is necessary

- Pulse dampening should be designed into the system

Dimensions2

2 Nominal length

LDFN 03 [1] [2] E [3] [4]

3 Pillar is a trademark of Nippon Pillar Packing Co.

Table 1

| Code | Removal Ratings |

| UFD | 0.05 μm |

| UFT | 0.1 μm |

| UFR | 0.2 μm |

Table 2

| Code | Inlet / Outlet | Vent / Drain |

| 06 2 | 3⁄8 in male | 1⁄4 in male |

| 7 | 3⁄8 in female | 1⁄4 in female |

| 08 2 | 1⁄2 in male | 1⁄4 in male |

2 06 and 08 are available for Flare style connection.

Table 3

| Code | Connections |

| 0 | Non-connection |

| 1 | 20 series (Flowell) |

| 2 | Super Pillar Type (Nippon Pillar) 3 |

| 51 | Flare style |

| 71 | Super Pillar 300 P series (Nippon Pillar) |

| 72 | Super Pillar 300 P series L type (Nippon Pillar) |

Table 4

| Code | Prewet Option |

| K3 | Prewet filter (packaged in DI water) |

| K7 | Prewet filter (packaged in DI water), Low metal extractables 4 |

3 Pillar is a trademark of Nippon Pillar Packing Co.

4 Please contact Pall on the extractable conditions.

5 Part numbers in conbination with all codes are not always availbale.

Please contact Pall for the part number availability.

We appreciate your review of this product. Please login to your account to leave a review.