FLHF Kleen-Change® Assembly

Datasheets

Download:The Pall FLUORYTE™ High Flow Filter is available in a Kleen-Change assembly with 0.1 μm and 0.05 μm retention ratings. The Pall Fluoryte filter offers a combination of proprietary PTFE membrane and specially engineered PTFE support material to provide superior flow performance for these sub-micron rated filters.

The Kleen-Change assembly is a completely disposable filter unit that combines the Fluoryte High Flow filter with Pall's all PFA housing. This provides a high flow disposable assembly option for today's demanding chemical applications. Designed for use where high flow, high temperature and pressure or high viscosity fluids require 0.05 μm retention.

The Kleen-Change assembly is a completely disposable filter unit that combines the Fluoryte High Flow filter with Pall's all PFA housing. This provides a high flow disposable assembly option for today's demanding chemical applications. Designed for use where high flow, high temperature and pressure or high viscosity fluids require 0.05 μm retention.

- All high purity fluoro-polymer materials ensures excellent cleanliness

- Very high flow rates

- Eliminates O-rings

- Low extractables

- Compatible with virtually all chemicals1

- 100% integrity tested

- Low metal ion extractable option

1 Consult Pall Microelectronics for recommendations for Hot Phosphoric or Hot Sulfuric, SPM, above 90 °C.

Materials

- Medium: PTFE

- Cartridge Hardware: High purity PFA

- Support: PTFE

- Housing: High purity PFA

Removal Rating

- 0.1 μm , 0.05 μm

Connections

Inlet, Outlet / Vent, Drain- 3⁄4 in. Male flare style / 1⁄4 in. Male flare style

- 3⁄4 in. Female Super Pillar2 S300 / 1⁄2 in. Female Super Pillar2 S300

Operating Conditions

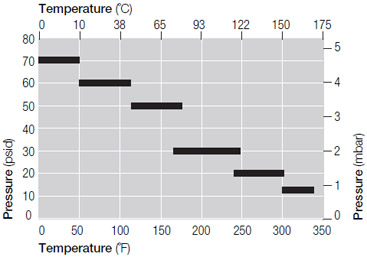

- Maximum Forward Differential Pressure:

5.5 bar @ 50 °C/80 psid @ 120 °F - Maximum Reverse Differential Pressure:

3.5 bar @ 20 °C/50 psid @ 68 °F

1 Consult Pall Microelectronics for recommendations for Hot Phosphoric or Hot Sulfuric, SPM, above 90 °C.

2 Pillar is a trademark of Pillar Packing Co.

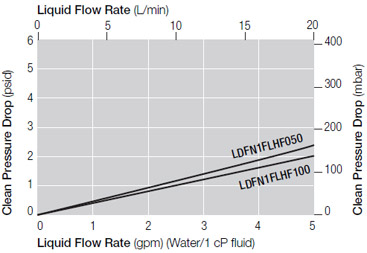

Pressure Drop vs. Liquid Flow Rate4

Assembly Temperature vs. Allowable Pressure

4 For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoises.

Filter Capsules

Operating Recommendations

- Available prewet as option (-K3)

- Proper wetting procedures should be followed if prewet option is not selected. IPA or other low surface tension wetting liquids need to be completely flushed out prior to chemical contact.

- Must allow for proper venting

- Pulse dampening should be designed into the system

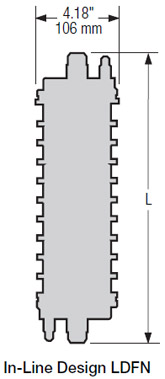

Dimensions

| Part Number5,6 | Removal | Connections Inlet, Outlet / Vent, Drain | L (mm / in.) |

| LDFN1FLHF10012E51 | 0.1 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN1FLHF10012E51-K3 | 0.1 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN1CFLHF10012E51-K3 | 0.1 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN09FLHF10012E51-K3 | 0.1 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 356 / 14 |

| LDFN09CFLHF10012E51-K3 | 0.1 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 356 / 14 |

| LDFN05FLHF10013E71-K3 | 0.1 | 3⁄4 in. Female Super Pillar S300 / 1⁄2 in. Female Super Pillar S300 | 248 / 9.8 |

| LDFN05CFLHF10013E71-K3 | 0.1 | 3⁄4 in. Female Super Pillar S300 / 1⁄2 in. Female Super Pillar S300 | 248 / 9.8 |

| LDFN1FLHF05012E51 | 0.05 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN1FLHF05012E51-K3 | 0.05 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN1CFLHF05012E51-K3 | 0.05 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 387 / 15.2 |

| LDFN09FLHF05012E51-K3 | 0.05 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 356 / 14 |

| LDFN09CFLHF05012E51-K3 | 0.05 | 3⁄4 in. Male flare style / 1⁄4 in. Male flare style | 356 / 14 |

| LDFN05FLHF05013E71-K3 | 0.05 | 3⁄4 in. Female Super Pillar S300 / 1⁄2 in. Female Super Pillar S300 | 248 / 9.8 |

| LDFN05CFLHF05013E71-K3 | 0.05 | 3⁄4 in. Female Super Pillar S300 / 1⁄2 in. Female Super Pillar S300 | 248 / 9.8 |

5 "K3" at end of part number added for prewet option.

6 "C" added following the assembly length (1,09,05) for ultra clean low metal extractable option.

Unit Conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.