Datasheets

Download:CMP StarKleen filter capsules are designed for the filtration of oxide and metal (including copper) slurries on or near tools used in chemical mechanical polishing (CMP).

- Compact, completely disposable, all polypropylene filter capsule with Flare style connections for easy changeout. Vents and drains are available with either NPT or Flare style fittings.

- The capsules contain either depth or pleated style Profile® filters. The relatively deep, wide pleats of the Profile Star filters easily handle fluids containing high suspended solids. This design results in low differential pressures, which minimize shear and provide long service life.

- The unique construction of these depth filters provides for built-in prefiltration assuring long service life with no breakthrough of contaminants nor shedding of filter medium.

- Profile depth filters provide a sharp boundary between transmission of native slurry particles and removal of gels and aggregates.

| Materials | Medium: Polypropylene |

| Core, cage: Polypropylene | |

| Shell: Polypropylene | |

| Removal Rating | 0.2 μm, 0.3 μm, 0.5 μm, 1 μm, 1.5 μm, 3 μm, 5 μm |

| Operating Conditions1 | Maximum operating pressure at ambient temperature: 0.5 MPa @ 25 °C / 73 psig @ 77 °F |

| Maximum operating pressure at maximum temperature: 0.2 MPa @ 40 °C / 30 psig @ 104 °F | |

| Maximum differential pressure: 0.3 MPa @ 25 °C / 45 psid @ 77 °F | |

| Connections | Inlet / outlet: 1 ⁄ 4" NPT, 1 ⁄ 4" Flare style, 3 ⁄ 8" Flare style |

| Vent / drain: 1 ⁄ 8" NPT, 1 ⁄ 4" Flare style | |

1 In compatible fluids which do not soften, swell, or adversely affect the filter performance or materials of construction.

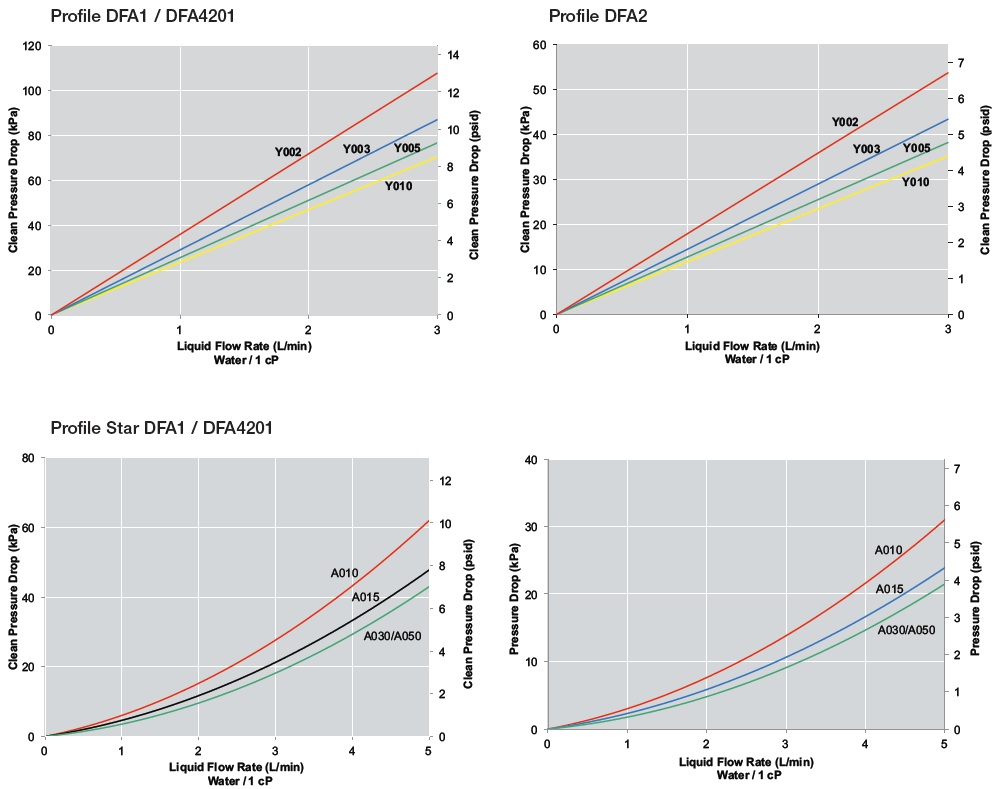

Typical Flow Characteristics – 1 cP fluid, 20 ºC

Filter Capsules

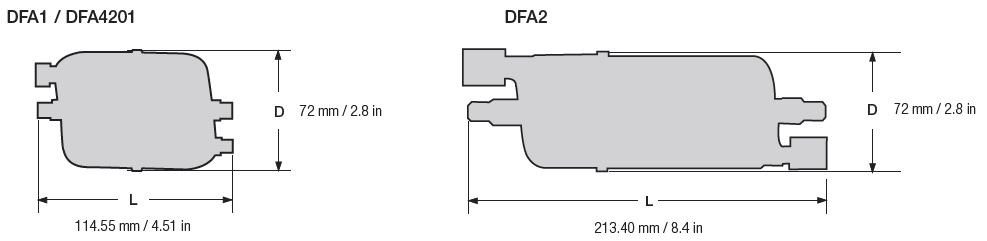

Dimensions

| Part Number | Filter Media | Removal Rating (μm) | Connections Inlet, outlet / Vent, drain |

| DFA1Y002FL4N2 | Profile | 0.2 | 1/4" Flare style / 1/8" NPT |

| DFA2Y002F64 | 0.2 | 3/8" Flare style / 1/4" Flare style | |

| DFA4201Y002 | 0.2 | 1/4" NPT / 1/8" NPT | |

| DFA1Y003FL4N2 | Profile | 0.3 | 1/4" Flare style / 1/8" NPT |

| DFA2Y003F64 | 0.3 | 3/8" Flare style / 1/4" Flare style | |

| DFA2Y003F6N4 | 0.3 | 1/4" NPT / 1/8" NPT | |

| DFA2Y010F64 | Profile | 1 | 3/8" Flare style / 1/4" Flare style |

| DFA4201Y010 | 1 | 1/4" NPT / 1/8" NPT | |

| DFA1A010FL4N2 | Profile Star | 1 | 1/4" Flare style / 1/8" NPT |

| DFA2A010F64 | 1 | 3/8" Flare style / 1/4" Flare style | |

| DFA4201A010 | 1 | 1/4" NPT / 1/8" NPT | |

| DFA1A015FL4N2 | Profile Star | 1.5 | 1/4" Flare style / 1/8" NPT |

| DFA2A015F64 | 1.5 | 3/8" Flare style / 1/4" Flare style | |

| DFA4201A015 | 1.5 | 1/4" NPT / 1/8" NPT | |

| DFA1A030FL4N2 | Profile Star | 3 | 1/4" Flare style / 1/8" NPT |

| DFA2A030F64 | 3 | 3/8" Flare style / 1/4" Flare style | |

| DFA4201A030 | 3 | 1/4" NPT / 1/8" NPT | |

| DFA1A050FL4N2 | Profile Star | 5 | 1/4" Flare style / 1/8" NPT |

| DFA2A050F64 | 5 | 3/8" Flare style / 1/4" Flare style | |

| DFA4201A050 | 5 | 1/4" NPT / 1/8" NPT | |

We appreciate your review of this product. Please login to your account to leave a review.