Datasheets

Download:The PE-Kleen filter combines the latest advances in polyethylene membrane technology with Pall’s unique crescent-shaped Ultipleat® filter technology. The result is a cartridge with the outstanding particle retention characteristics required by the semiconductor industry.

The PE-Kleen filter is specifically designed for the filtration of ultra-high-purity chemicals. It is recommended for applications involving antireflective coatings and bulk filtration of 248 nm and 193 nm photoresist. The XP option is available for advanced lithography processes.

Features

- Excellent gel-retention characteristics

- High flow rates

- Low extractables

- 100% integrity tested

- Manufactured in a cleanroom

- Minimized organic extractables by XP option

- XP option guarantees low organic, metal and particle cleanliness for the most advanced processes.

Materials of Construction

| Components | Materials |

| Filter medium | HDPE |

| Support and drainage | HDPE |

| Core, cage and end caps | HDPE |

| O-ring options | EPR, FEP Encapsulated fluoroelastomer and Perfluoroelastomer |

| ABD Filters | ||||||

| Removal Ratings | 2 nm | 5 nm | 10 nm | 30 nm | 0.05 μm | 1.0 μm |

| Filter Areas | 1.3 m2 | 1.3 m2 | 1.3 m2 | 1.1 m2 | 1.4 m2 | 1.1 m2 |

| Maximum Operating Temperature | 50 ˚C / 122 ˚F | |||||

| Maximum forward differential pressure | 340 kPa @ 40 ˚C / 49 psid @ 104 ˚F | |||||

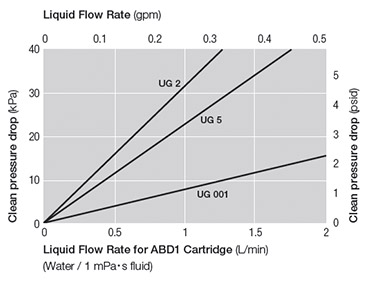

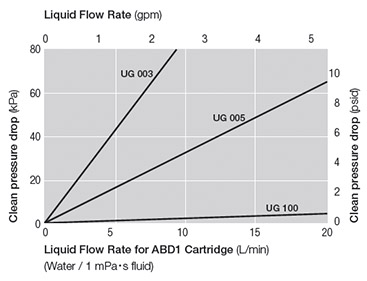

Pressure Drop vs. Liquid flow Rate (Water, 20 °C)

Part Numbers / Ordering Information1, 2

ABD [1] UG [2] [3] E [4]

Table 1

| Code | Nominal length (mm / in) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

Table 2

| Code | Removal Ratings |

| 2 | 2 nm |

| 5 | 5 nm |

| 001 | 10 nm |

| 003 | 30 nm |

| 005 | 0.05 μm |

| 100 | 1.0 μm |

Table 3

| Code | Configurations |

| 3 | 222 O-ring open end flat closed end |

| 7 | 226 O-ring open end fin on closed end |

| 8 | 222 O-ring open end fin on closed end |

Table 4

| Code | O-ring Materials |

| J | EPR |

| H1 | FEP Encapsulated fluoroelastomer |

| H11 | Perfluoroelastomer |

1Filter elements may not be available in all configurations. Contact your local Pall representative for availability.

2For XP option, add –XP to end of part number for 2 - 10nm removal ratings and 10 - 20 inches.

We appreciate your review of this product. Please login to your account to leave a review.