Datasheets

Download:The Mini Gaskleen Hi-Flow filter assembly is designed for ultra-high-purity point-of-use gas filtration applications. The unique filter design allows significantly higher flow capacity than previously offered in this envelope.

- 316L stainless steel electropolished housing

- All-fluoro-polymer element

- Wide range of chemical compatibility

- High temperature and pressure capabilities

- Compact size for ease of installation

- 100% integrity tested

- Cleanroom manufactured and packaged

- 100% helium leak tested

- Housing meets or exceeds VIM VAR material specifications

| Components | Materials |

| Filter Medium | PTFE |

| Core | PFA |

| O-ring | FEP encapsulated fluorocarbon |

| Internal Surface Finish | ≤ 0.13 μm / 5 μin Ra (gasket and butt weld fittings) ≤ 0.50 μm / 20 μin Ra (compression fittings) |

| Housing | Electropolished 316L stainless steel Housing material meets or exceeds VIM / VAR specifications. EU pressure equipment directive: Assemblies have been evaluated and designed using SEP per the European Union’s Pressure Equipment Directive 2014/68/EU and are not CE marked. |

| Internal housing surface chemistry | Cr:Fe (1:1) chromium-enriched |

| Removal Rating | 1.5 nm |

| Connections |

|

| Leak Rating | 100% helium leak tested to 10-9 atm cm3 / sec Design validated to 10-11 atm cm3 / sec |

| Maximum Operating Pressure | 20.7 MPa @ 121 °C / 3000 psig @ 250 °F |

| Maximum Forward Differential Pressure | 0.69 MPa @ 40 ºC / 100 psid @ 104 ºF |

| Maximum Reverse Differential Pressure | 0.34 MPa @ 21 °C / 50 psid @ 70 °F |

1 VCR and Swagelok are registered trademarks of Swagelok Company.

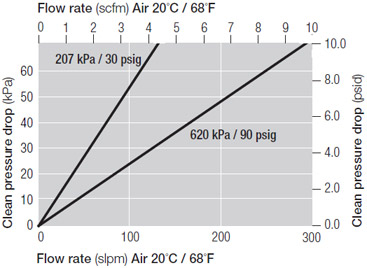

Pressure Drop vs. Gas Flow Rate

Preconditioned Options (3102 Series)

- < 10 ppb moisture contribution (qualified per SEMASPEC test method #90120397B-STD)

- < 10 ppb THC contribution (qualified per SEMASPEC test method #90120396B-STD)

- < 10 ppb O2 contribution (qualified per SEMASPEC test method #90120398B-STD)

- No particle contribution above background ≤ 1 particle/(m3 or ft3)

Filter Capsules

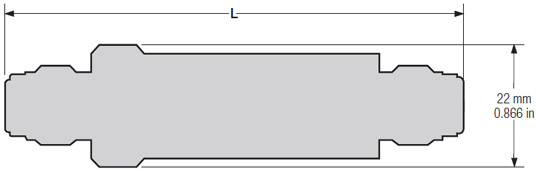

Dimensions

| Part Number | Description | Preconditioned | |

| GLFPF3101VMM4 | 1⁄4 in. Gasket seal (VCR or compatible) male/male | 84 / 3.31 | No |

| GLFPF3101BW4 | 1⁄4 in. Butt weld, 0.89 mm / 0.035 in. wall | 90 / 3.54 | No |

| GLFPF3101SM4 | 1⁄4 in. Compression seal, male inlet/outlet (Swagelok compatible) | 73 / 2.88 | No |

| GLFPF3101VFM4 | 1⁄4 in. Gasket seal (VCR or compatible) female inlet/male outlet | 88 / 3.47 | No |

| GLFPF3101VMF4 | 1⁄4 in. Gasket seal Outlet (VCR or compatible) male inlet/female outlet | 100 / 3.94 | No |

| GLFPF3102VMM4 | 1⁄4 in. Gasket seal (VCR or compatible) male/male | 84 / 3.31 | Yes |

| GLFPF3111VMM4 | 1⁄4 in. Gasket seal (VCR or compatible) male/male | 127 / 5.00 | No |

Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.