Datasheets

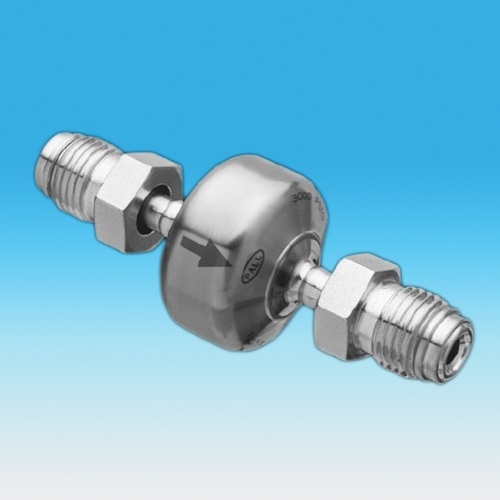

Download:The Ultramet-L® 4000 Series Filter Assembly is a unique, all 316L stainless steel filter designed for ≥ 1.5 nanometer filtration of semiconductor process gases.

- All 316L stainless steel construction

- State-of-the-art 316L stainless steel media

- Excellent particle removal efficiency vs. pressure drop

- Accommodates extremely high flow rates for the assembly size

- Excellent gas displacement and desorption characteristics

- High temperature and pressure capabilities

- Compact size for ease of installation

- Wide variety of fitting options available

- 100% helium leak tested

- Cleanroom manufactured and packaged

- VAR PLUS housing material meets or exceeds VIM VAR specifications

| Filter Medium | 316L stainless steel |

| Internal Surface Finish | ≤ 7 μin / 0.18 μm Ra |

| Housing | Electropolished 316L stainless steel Housing material meets or exceeds VIM / VAR specifications |

| Removal Rating | ≥ 1.5 nm |

| Particle Removal Characteristics | 109 particle reduction up to 6 slpm / 0.2 scfm |

| 104 particle reduction up to 75 slpm / 2.6 scfm | |

| Connections | 1⁄4", 1⁄2" Gasket Seal, Male / Male (VCR1 or compatible) |

| 1⁄4" Compression Seal, Male / Male (Swagelok1 or compatible) | |

| 1⁄4" Butt Weld (0.035" / 0.89 mm wall) | |

| Leak Rating | 100% helium leak tested to 10-9 atm•cc/s |

| Design validated to 10-11 atm•cm3/s | |

| Maximum Operating Pressure | 3000 psig @ 100 °F / 207 bar @ 38 °C 1685 psig @ 840 °F / 1 16 bar @ 450 °C |

| Maximum Allowable Differential Pressure | 125 psid @ 100 °F / 8.6 bar @ 38 °C 60 psid @ 840 °F / 4.1 bar @ 450 °C |

| EU pressure equipment directive | Assemblies have been evaluated and are CE marked per the European Union’s Pressure Equipment Directive 2014/68/EU |

1 VCR and Swagelok are trademarks of Swagelok Co.

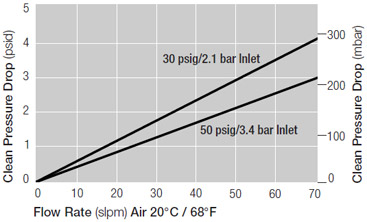

Pressure Drop vs. Gas Flow Rate

Assemblies

Filtration

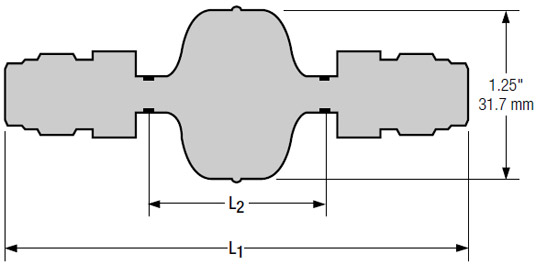

Dimensions

| Part Number | Description | |

| GLFF4000VM4 | 1⁄4 in. Gasket Seal (VCR or Compatible) Male/Male | 3.31 / 84 (L1) |

| GLFF4000SM4 | 1⁄4 in. Compression Seal (Swagelok or Compatible) Male/Male | 2.88 / 73 (L1) |

| GLFF4000BW4 | 1⁄4 in. Butt Weld, 0.035 in. / 0.89 mm wall | 1.75 / 45 (L2) |

| GLFF4000VMM8 | 1⁄2 in. Gasket Seal (VCR or Compatible) Male/Male | 3.35 / 85 (L1) |

Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.