Datasheets

Download:The Ultramet-L® 4281/4581 Series Filter Assemblies are available with an all 316L stainless steel housing and either a 316L stainless steel or nickel filter. They are designed for ≥ 1.5 nanometer (0.001.5 μm) filtration of semiconductor grade gases. The 4281/4581 series filters are recommended for all applications with process gases that are compatible with 316L stainless steel or nickel. For applications with corrosive gases, such as halogen containing acid gases, the nickel filter assembly is recommended only if the gas is known to be anhydrous.

- State-of-the-art 316L stainless steel or nickel media

- Excellent particle removal efficiency vs. pressure drop

- Accommodates extremely high flow rates for the assembly size

- Excellent gas displacement and desorption characteristics

- High temperature and pressure capabilities

- Compact size for ease of installation

- Wide variety of fitting options available

- 100% helium leak tested

- Cleanroom manufactured and packaged

- Housing material meets or exceeds VIM VAR specifications.

| Filter Medium | 316L stainless steel or nickel |

| Internal Surface Finish | 10 μin / 0.25 μm Ra |

| Housing | Electropolished 316L stainless steel Housing material meets or exceeds typical VIM VAR specifications |

| Removal Rating | ≥ 1.5 nm |

| Particle Removal Characteristics | 4281 series: 109 particle reduction up to 6 slpm / 0.2 scfm 104 particle reduction up to 75 slpm / 2.6 scfm |

| 4581 series: 109 particle reduction up to 50 slpm / 1.76 scfm |

|

| Connections | 1⁄4" Gasket Seal, male (VCR1 or compatible) |

| Other fitting configurations available, please contact Pall | |

| Leak Rating | 100% helium leak tested to 10-9 atm•cm3/sec |

| Design validated to 10-11 atm•cm3/sec | |

| Maximum Operating Pressure | 3,000 psig @ 100 °F / 207 bar @ 38 °C; 1,685 psig @ 840 °F / 116 bar @ 450 °C |

| Maximum Allowable Differential Pressure | 125 psid @ 100 °F / 8.6 bar @ 38 °C; 60 psid @ 840 °F / 4.1 bar @ 450 °C |

| EU pressure equipment directive | Assemblies have been evaluated and are CE marked per the European Union’s Pressure Equipment Directive 2014/68/EU |

1 VCR is a trademark of Swagelok Co.

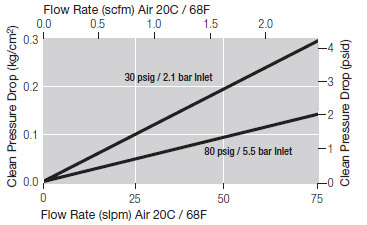

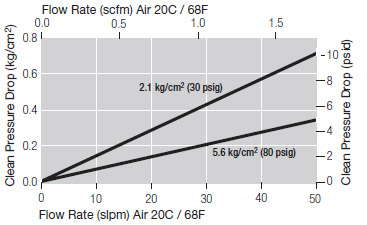

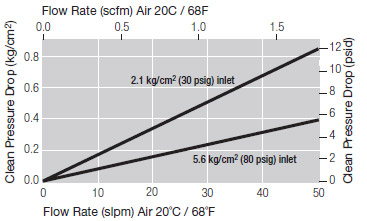

Pressure Drop vs. Gas Flow Rate

GLFF4281VMM4

GLFF4581VMM4

GLFN4581VMM4

Assemblies

Filtration

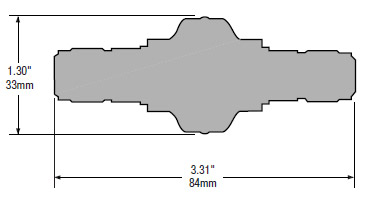

Dimensions

| Part Number | Description | Fitting Type |

| GLFF4281VMM4 | All Stainless Steel | 1⁄4 in. Gasket Seal (VCR or Compatible) Male / Male |

| GLFF4581VMM4 | All Stainless Steel | 1⁄4 in. Gasket Seal (VCR or Compatible) Male / Male |

| GLFN4581VMM4 | Nickel Media, 316L Stainless Steel Housing | 1⁄4 in. Gasket Seal (VCR or Compatible) Male / Male |

Unit conversion: 1 kilogram per square centimeter = 98.067 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.