Microza UF Modules, OLT Series

Datasheets

Download:The Microza1OLT ultrafiltration (UF) modules feature hollow fiber membranes having a uniformly smooth, tight skin on both the inside and outside of the fiber.

- Low metal extractables by pre elution using new hot water rinsing process

- Up to 24 months on shelf life ex works due to hot water sanitization2

- Shipped water wet

- Designed specifically for ultra high purity water

- Polysulfone membranes and housings

- 6,000 and 10,000 molecular weight cut off ratings

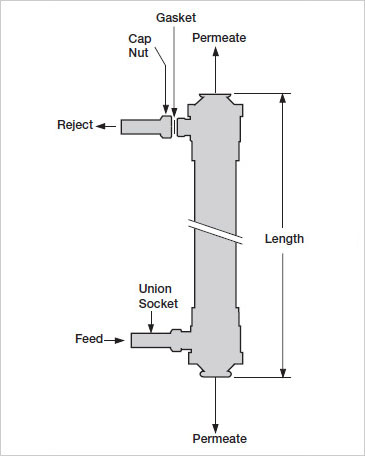

- External feed:

- Feed water flows from the outside to the inside of the hollow fiber. This flow path produces exceptionally clean water and eliminates stagnant areas on the permeate side.

- Large membrane area results in high flow rates per module

- High temperature and pressure modules available

1Microza is a trademark of Asahi Kasei Corporation

2Recommended storage conditions: no direct sunlight, packaging unopened,ambient temperature (max 25 °C), do not freeze

3Tri-Clamp is a trademark of Ladish Co., Inc.

Connections

Feed/Reject: PVDF union sockets for these ports are available for thermal fusion to PVDF piping.Permeate:Connections are 2 in. or 2 1⁄2 in. 3 piece clamp

Operating Parameters

| OLT-6036HAW | OLT-6036VAW | OLT-6036SAW | ||

| Performance | ||||

| Molecular weight cut-off (nominal) | daltons | 6,000 | 6,000 | 6,000 |

| Initial clean permeate flow4,5 | m3/h | 16 | 16 | 16 |

| gpm | 70 | 70 | 70 | |

| Dimensions | ||||

| Fiber inner/outer diameter | mm | 0.6 / 1.0 | 0.6 / 1.0 | 0.6 / 1.0 |

| Membrane area | m2 | 34 | 34 | 34 |

| ft2 | 366 | 366 | 366 | |

| Module length | mm | 1,177 | 1,177 | 1,177 |

| in. | 46.3 | 46.3 | 46.3 | |

| Module diameter6 | mm | 172 | 179 | 172 |

| in. | 6.8 | 7.1 | 6.8 | |

| Weight | kg | 32 | 34 | 33 |

| lb | 71 | 75 | 73 | |

| Operating Conditions7 | ||||

| Maximum inlet pressure (40°C / 104°F) |

MPa | 0.9 | 0.9 | 1.2 |

| psi | 130 | 130 | 174 | |

| Maximum transmembrane pressure (40°C / 104°F) |

MPa | 0.3 | 0.3 | 0.3 |

| psi | 45 | 45 | 45 | |

| Maximum operating temperature | °C | 40 | 80 | 40 |

| °F | 104 | 176 | 104 | |

| Maximum sanitizing temperature | °C | 90 | 90 | 90 |

| °F | 194 | 194 | 194 | |

| pH range | 1-14 | 1-14 | 1-14 | |

| Materials | ||||

| Membrane | Polysulfone | |||

| Housing | Polysulfone; V and S grades have outer fiberglass reinforcement | |||

| End caps | Polyphenylsulfone | |||

| Collar nuts8 | Fiberglass reinforced polyphenylene ether; S grade – aluminum | |||

| Cap nuts8 | Fiberglass reinforced polyphenylene ether | |||

| Potting material | Epoxy resin | |||

| Gasket | fluoro-polymer elastomer | |||

| Transportation Liquid | Ultrapure water | |||

4 Initial clean water permeate flow at 25 °C / 77 °F and 0.1 MPa / 14.5 psi average transmembrane pressure.

Please consult manual for general operating guidelines.

5 DESIGN FLUX IS 80% OF THIS VALUE (12.5 m3 / h or 55 GPM)

6 Nominal shell diameter excluding headers and permeate ports. Note the diameter of the dummy module used for fit-up is 172 mm / 6.8 in.

7 Pressure must be reduced at higher temperatures. See tables on following pages.

8 Non-wetted parts

| OLT-5026APW | ||||||

| Performance | ||||||

| Molecular weight cut-off (nominal) | daltons | 10,000 | ||||

| Initial clean permeate flow9,10 | m3/h | 7.5 | ||||

| gpm | 33 | |||||

| Dimensions | ||||||

| Fiber inner/outer diameter | mm | 0.6 / 1.1 | ||||

| Membrane area | m2 | 23 | ||||

| ft2 | 248 | |||||

| Module length | mm | 1,147 | ||||

| in. | 45.1 | |||||

| Module diameter | mm | 149 | ||||

| in. | 5.81 | |||||

| Weight | kg | 23 | ||||

| lb | 51 | |||||

| Operating Conditions11 | ||||||

| Maximum inlet pressure (40°C / 104°F) |

MPa | 0.9 | ||||

| psi | 130 | |||||

| Maximum transmembrane pressure (40°C / 104°F) |

MPa | 0.3 | ||||

| psi | 45 | |||||

| Maximum operating temperature | °C | 80 | ||||

| °F | 176 | |||||

| Maximum sanitizing temperature | °C | 90 | ||||

| °F | 194 | |||||

| pH range | 1-14 | |||||

| Materials | ||||||

| Membrane | Polysulfone | |||||

| Housing | Polysulfone; V and S grades have outer fiberglass reinforcement | |||||

| End caps | Polyphenylsulfone | |||||

| Cap nuts12 | High temperature PVC | |||||

| Potting material | Epoxy resin | |||||

| Gasket | Fluoropolymer elastomer | |||||

| Transportation Liquid | Ultrapure water | |||||

9 Initial clean water permeate flow at 25 °C / 77 °F and 0.1 MPa /14.5 psi average transmembrane pressure.

Please consult manual for general operating guidelines.

10 DESIGN FLUX IS 80% OF THIS VALUE

11 Pressure must be reduced at higher temperatures. See tables on following pages.

12 Non-wetted parts

Operating Pressure vs Water Temperature

The allowable operating pressure will vary with water temperature. See tables below.Part Number: OLT-6036HAW

| UF Feed Temperature °C / °F | Maximum Transmembrane Pressure | Maximum Feed Pressure | Maximum Permeate Pressure |

| 0-30 / 32-86 | 0.3 MPa / 45 psi | 0.9 MPa / 130 psi | 0.9 MPa / 130 psi |

| 80-90 / 176-19413 | 0.1 MPa / 15 psi | 0.35 MPa / 50 psi | 0.35 MPa / 50 psi |

Part Number: OLT-6036VAW

| UF Feed Temperature °C / °F | Maximum Transmembrane Pressure | Maximum Feed Pressure | Maximum Permeate Pressure |

| 0-70 / 32-158 | 0.2 MPa / 30 psi | 0.9 MPa / 130 psi | 0.9 MPa / 130 psi |

| 70-80 / 158-176 | 0.1 MPa / 15 psi | 0.8 MPa / 116 psi | 0.8 MPa / 116 psi |

| 80-90 / 176-19413 | 0.1 MPa / 15 psi | 0.5 MPa / 73 psi | 0.5 MPa / 73 psi |

Part Number: OLT-6036SAW

| UF Feed Temperature °C / °F | Maximum Transmembrane Pressure | Maximum Feed Pressure | Maximum Permeate Pressure |

| 0-30 / 32-86 | 0.3 MPa / 45 psi | 1.2 MPa / 174 psi | 1.2 MPa / 174 psi |

| 80-90 / 176-19413 | 0.1 MPa / 15 psi | 0.5 MPa / 73 psi | 0.5 MPa / 73 psi |

Part Number: OLT-5026APW

| UF Feed Temperature °C / °F | Maximum Transmembrane Pressure | Maximum Feed Pressure | Maximum Permeate Pressure |

| 0-30 / 32-86 | 0.3 MPa / 45 psi | 0.9 MPa / 130 psi | 0.9 MPa / 130 psi |

| 30-50 / 86-122 | 0.3 MPa / 45 psi | 0.75 MPa / 109 psi | 0.75 MPa / 109 psi |

| 50-70 / 122-158 | 0.2 MPa / 30 psi | 0.65 MPa / 94 psi | 0.65 MPa / 94 psi |

| 70-80 / 158-176 | 0.15 MPa / 22 psi | 0.6 MPa / 87 psi | 0.6 MPa / 87 psi |

| 80-90 / 176-19413 | 0.1 MPa / 15 psi | 0.55 MPa / 80 psi | 0.55 MPa / 80 psi |

The OLT modules are recommended for high purity water systems where the TOC is less than 20 ppb and the particle counts in the feed are as shown in the table below.

Feed Conditions

| Particle Size | Maximum no. of particles/ml |

| > 0.1 μm | 100 |

| > 0.2 μm | 20 |

TFF Cassettes and Modules

Filtration, Purification

Dimensions

Module

| Part Number | Permeate Connection Size | Feed and Reject Connection Size | |||

| OLT-6036HAW | 2 1⁄2" 3 piece clamp | 63 mm O.D. | |||

| OLT-6036VAW | 2 1⁄2" 3 piece clamp | 63 mm O.D. | |||

| OLT-6026SAW | 2 1⁄2" 3 piece clamp | 63 mm O.D. | |||

| OLT-5026APW | 2" 3 piece clamp | 40 mm O.D. | |||

Spare Parts

| Description | Material | Module Spare Part Numbers13 | ||

| OLT-6036H | OLT-6036V | OLT-6036S | ||

| Union Socket | PVDF | AUME-OT60H-31 0450602 |

AUME-OT60H-31 0450602 |

AUME-OT60H-31 0450602 |

| Cap Nut | GF reinforced PPE | AUME-OT60H-13b 0450600 |

AUME-OT60H-13b 0450600 |

AUME-OT60H-13b 0450600 |

| Cap Nut Retainer Ring | GF reinforced PPE | AUME-OT60H-13a 0450601 |

AUME-OT60H-13a 0450601 |

AUME-OT60H-13a 0450601 |

| Permeate Gasket | Fluropolymer elastomer | AUME-OT60H-17 0150612 |

AUME-OT60H-17 0150612 |

AUME-OT60H-17 0150612 |

| Feed/Reject O-Ring | Fluropolymer elastomer | AUME-OT60H-14 0150611 |

AUME-OT60H-14 0150611 |

AUME-OT60H-14 0150611 |

| Dummy | Polysulfone | AUME-OT60H-30 0450608 |

AUME-OT60H-30 0450608 |

AUME-OT60H-30 0450608 |

| Description | Material | Module Spare Part Numbers1 | ||

| OLT-5026AP | ||||

| Union Socket | PVDF | AUME-OT50G-20 0450504 |

||

| Cap Nut | Stainless steel or PVDF | AUME-OT50G-13 0450558 (Stainless steel / PFA coating |

||

| Permeate Gasket | Fluropolymer elastomer | AUME-OT50G-17 0150328 |

||

| Feed/Reject O-Ring | Fluropolymer elastomer | AUME-OT50G-14 0150550 |

||

| Dummy | Polysulfone | AUME-OT50G-30 0450570 |

||

14Spare parts can be ordered by either part number

We appreciate your review of this product. Please login to your account to leave a review.