Datasheets

Download:Varafine filters are well suited for ultra high purity DI water applications where very fine removal ratings and extremely high flow rates are required for economical installations. These filters contain a highly asymmetric polysulfone membrane that results in exceptionally low pressure drop values.

- Available in removal ratings from 0.02 μm to 0.45 μm

- Double layer, patented highly asymmetric polysulfone membrane

- Rapid rinse-up

- Integrity testable

- Manufactured in cleanroom environment

Materials

- Medium: hydrophilic asymmetric polysulfone

- Core, cage and endcaps: polypropylene

- Support and drainage: polypropylene

- Sealing method: thermal bond

- O-ring/gasket: silicone elastomer (standard)

Removal Ratings

- 0.02 μm, 0.1 μm, 0.2 μm, 0.45 μm

Configurations

- Nominal length:

- 102 mm/4 in.

- 254 mm/10 in.

- 508 mm/20 in.

- 762 mm/30 in.

- 1016 mm/40 in.

- Diameter: 66 mm/2.6 in.

- O-ring size/end caps:

- Code M3 (222 double O-rings/flat end)

- Code M8 (222 double O-rings/finned end)

- Code M7 (226 double O-ring/bayonet lock/finned end)

Operating Conditions

- Maximum operating temperature: 30 °C / 86 °F (70 °C / 158 °F)1

- Maximum forward differential pressure:

- 0.5 MPa @ 20 °C / 80 psid @ 68 °F

- 0.14 MPa @ 70 °C / 20 psid @ 158 °F

Integrity Test Values2

Per 254 mm / 10 in segment- 0.02 μm <30 cm3/min @ 50 psig / 0.34 MPa

- 0.1 μm <24 cm3/min @ 25 psig / 0.17 MPa

- 0.2 μm <20 cm3/min @ 20 psig / 0.14 MPa bar

- 0.45 μm <15 cm3/min @ 15 psig / 0.1 MPa

2 Test fluid used is 100% H2O.

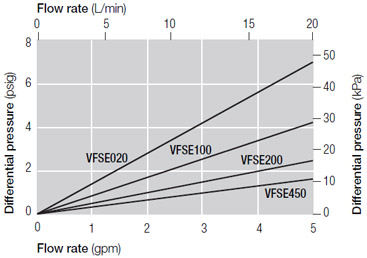

Pressure Drop vs. Liquid Flow Rate

Varafine VFSE Filter Cartridges

Filter Cartridges

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Example Part Number: VFSE 100 30 M7 T ( See bold references in tables below)

Part Number:

VTSE < Removal Rating Code from Table 1 > < Nominal Length Code from Table 2> < Cartridge End Configuration Code from Table 3 > < O-ring Material Code from Table 4 >

Unit conversion: 1 bar = 100 kilopascals

Example Part Number: VFSE 100 30 M7 T ( See bold references in tables below)

Part Number:

VTSE < Removal Rating Code from Table 1 > < Nominal Length Code from Table 2> < Cartridge End Configuration Code from Table 3 > < O-ring Material Code from Table 4 >

Table 1 - Removal Rating (µm)

| Code | Removal Rating (μm) |

| 020 | 0.02 |

| 100 | 0.1 |

| 200 | 0.2 |

| 450 | 0.45 |

Table 2 - Nominal Length (in / mm)

| Code | Nominal Length (in / mm) |

| 4 | 102/4 |

| 10 | 254/10 |

| 20 | 508/20 |

| 30 | 762/30 |

| 40 | 1016/40 |

Table 3 - Cartridge End Configuration

| Code | Cartridge End Configuration |

| M3 | SOE flat closed end, 222 O-rings |

| M7 | SOE fin end, 226 O-rings |

| M8 | SOE fin end, 222 O-rings |

| DOE | Double open end |

Table 4 - O-ring Material

| Code | O-ring Material |

| S | Silicone |

| E | EPDM |

| V | Viton3 A |

| T | Teflon3 encapsulated silicone |

| F | Teflon encapsulated Viton A |

3 Viton and Teflon are trademarks of E. I. du Pont de Nemours and Company.

Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.