Datasheets

Download:The Posidyne UP filter is well suited for ultrapure water application for today's advanced semiconductor manufacturers. These filter cartridges utilize the crescentshaped Ultipleat® filter design, the latest advancement in filter technology, along with the benefit of a positive zeta potential.

- Excellent particle removal efficiency

- Positive zeta potential charge over a wide pH range

- Two removal ratings available

- Integrity testable

- Many configurations available

- High flow rates

- Low extractables

- Quick rinse-up

- Manufactured in a cleanroom environment

- 100% integrity tested

Materials

- Medium: Nylon 6,6 positively charged

- Core and cage: Polypropylene

- End caps: Polyester

- Support and drainage: Polyester

- O-ring options: Silicone

Removal Ratings

- 0.1 μm, 0.04 μm

Filter Areas

- 1.4 m2 / 15 ft2 per 254 mm / 10 in. segment

Configurations

- Nominal length:

- 254 mm / 10 in.

- 508 mm / 20 in.

- 762 mm / 30 in.

- 1016 mm / 40 in.

- Diameter: 70 mm / 2.75 in.

- O-ring size/end caps:

- Code 3 (222 double O-ring / flat end)

- Code 8 (222 double O-ring / finned end)

- Code 7 (226 double O-ring / bayonet lock / finned end)

Performance Characteristics

- Resistivity rinse-up to 18 megohm-cm: < 35 minutes

- Single digit ppb TOC rinse-up: < 35 minutes

Operating Characteristics

- Maximum Operating Temperature: 50 °C / 120 °F

- Maximum Differential Pressure: 0.41 MPa @ 50 °C / 60 psid @ 120 °F

Integrity Test Values1

Per 254 mm / 10 in segment- 0.04 μm < 18.8 cm3/min @ 0.28 MPa / 40 psig

- 0.1 μm < 50 cm3/min @ 0.35 MPa / 50 psig

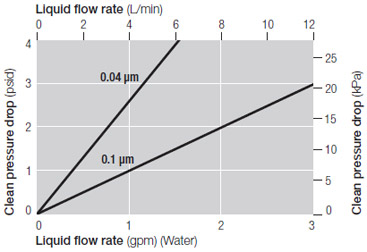

Typical Flow Characteristics – 1 cP fluid, 20 ºC

Cartridge Style AB1

Filter Cartridges

Part Numbers

AB [1] U [2] Z [3] E [4]

Table 1

| Code | Nominal Length (mm / in) |

| 1 | 254 / 10 |

| 2 | 508 / 20 |

| 3 | 762 / 30 |

| 4 | 1016 / 40 |

Table 2

| Code | Removal Rating (μm) |

| ND | 0.04 |

| NI | 0.1 |

Table 3

| Code | O-Ring Standard | Type |

| 7 | AS568A-226 | Bombfin |

| Bayonet Lock | ||

| 8 | AS568A-222 | Finned End |

| Plug-in | ||

| 3 | AS568A-222 | Flat End |

| Plug-in | ||

Table 4

| Code | O-Ring Material2 |

| H1 | FEP Encapsulated Fluoroelastomer |

| H4 | Silicone |

2 Other O-ring materials are available, such as ultrapure clear silicone (H26 instead of H4)

We appreciate your review of this product. Please login to your account to leave a review.