XpressKleen™ JKC Assemblies

Datasheets

Download:The Pall XpressKleen JKC disposable assembly uses a new generation of surface modified and patent pending PTFE membrane designed for leading edge critical chemical processes.

The XpressKleen JKC filter provides control of critical size particles and maintains critical fluid purity with a product guarantee of less than 3 ppb of total metal ion extractables1. The XpressKleen filter's surface cleanliness includes removal of organic contamination and surface particles. This makes the filter suitable for use in point of use (POU) and at the point of process (POP) to help fabs define a contamination control system that delivers the required fluid purity to the wafer.

This is accomplished by Pall's completely integrated and advanced manufacturing capability that extends from the PTFE resin to the finished filter device. The filter cleanliness reduces process downtime and delivers fast qualification following filter change.

The XpressKleen JKC ( Junior Kleen-Change® ) assembly is a completely disposable filter unit designed for critical single pass use.

Features

- Low extractables1,2 ‹3 ppb total of 13 elements, ‹0.1ppb(Ni), ‹0.2ppb(Cu)

- 40nm particle rinse up control in UPW

- TOC control

- 100% prewetted shipment with ultrapure water package

- Small size designed KC assembly for critical singlepass and POU retention

- Disposable filter unit with filter cartridge integrally sealed in housing

- Sealed assembly for safer handling and faster change-out

- 100% integrity tested

1 Total metal concentrations in 13 elements: Li, Na, Mg, Al, K, Ca, Cr, Mn, Fe, Ni, Cu, Zn, Pb. Consult factory

for conditions.

2 XP10 nm has ≤1ppb of total metal ion concentration per single length filter.

Materials of Construction3

| Components | Materials |

| Filter Medium | Surface modified PTFE |

| Media Support | PFA |

| Core / Outer Cage | PFA |

| End Caps | PFA |

| Housing | PFA |

3 All fluoro-polymer materials made without PFOA.

Removal Ratings and Operating Conditions

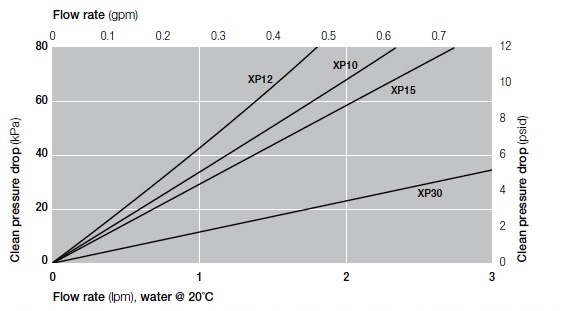

| Removal Ratings | 10 nm | 12 nm | 15nm | 30nm |

| Media code | XP10 | XP12 | XP15 | XP30 |

| Configurations | In-line | |||

| Nominal Filter Area | 1300 cm2 / 1.4 ft2 | |||

| Maximum Operating Temperature | 120 °C / 248 °F | |||

| Maximum Operating Pressure | 0.50 MPaG ‹ 40 °C / 73 psig ‹ 144 °F 0.20 MPaG ‹ 90 °C / 28 psig ‹ 194 °F 0.15 MPaG ‹ 120 °C / 21 psig ‹ 248 °F |

|||

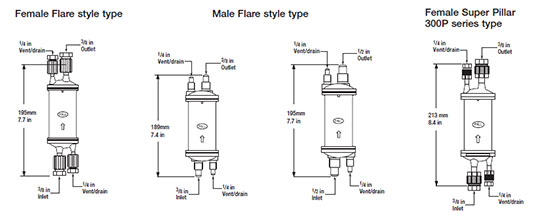

Nominal Dimensions

Typical Flow Characteristics - 1cP fluid, 20℃

Part Numbers / Ordering Information4

LDFN03XP [1] [2] E [3]

Table 1

| Code | Removal Ratings |

| 10 | 10nm |

| 12 | 12 nm |

| 15 | 15 nm |

| 30 | 30 nm |

Table 2

| Code | Inlet / Outlet | Vent / Drain |

| 06 5 | ⅜ in male | ¼ in male |

| 7 | ⅜ in female | ¼ in female |

| 08 5 | ½ in male | ¼ in male |

Table 3

| Code | Connections |

| 1 | 20 series (Flowell) 6 |

| 2 | Super Pillar Type 7 |

| 51 | Flare style |

| 71 | Super Pillar 300 P series |

| 72 | Super Pillar 300 P series L type |

4 Part numbers in combination with all codes are not always available. Please contact Pall for the part number availability.

5 06 and 08 are available with Flare style connection.

6 Flowell is a trademark of Flowell Corporation.

7 Super Pillar is a trademark of Nippon Pillar Packing Co.

We appreciate your review of this product. Please login to your account to leave a review.