Datasheets

Download:Lithography Filter for Leading-edge Process

The PhotoKleen™ NTD filter capsule is designed for aggressive organic solvent applications, in advanced, high through-put track systems.

It is available in three filter configurations designed for point of use on advanced track systems (PhotoKleen EZD3X / PHF12, Photokleen EZD3XL / PHF13) and for chemical cabinet feed system (PhotoKleen EZD / PHF23)

The PhotoKleen™ NTD filter utilizes an all fluoropolymer construction for the ultimate compatibility and cleanliness. It also offers extremely low pressure drop.

Features

- Easy change out style filter capsule

- Minimized hold-up volume, and top in / top out flow direction, with inlet flow stream down to the bottom

- Guaranteed metal, particle and organic cleanliness1

Benefits

Offers extremely low delta-P, enabling use in higher viscosity fluids

Reduces tool down time during filter start up and change out

Offers optimized membrane for target application

1 Contact Pall technical service for device claims

Materials of Construction

| Components | Materials2 |

| Filter Medium | Functionalized PTFE |

| Support and Drainage | PFA |

| Core, Cage and End Caps | PFA |

| Housing | PFA |

| O-ring |

Perfluoroelastomer |

2 All fluoropolymer materials made without PFOA

| Removal Ratings | 5 nm |

| Filter Areas | PHF12 : 1,200 cm2 PHF13 : 2,400 cm2 PHF23 : 2,400 cm2 |

| Maximum Operating Temperature | PHF12, PHF13 : 30 °C / 86 °F PHF23 : 23 °C / 73 °F |

| Maximum Operating Pressure | PHF12, PHF13 : 0.29 MPaG @ 30 °C /42 psig @ 86 °F PHF23 : 0.39 MPaG @ 23 °C /57 psig @ 73 °F |

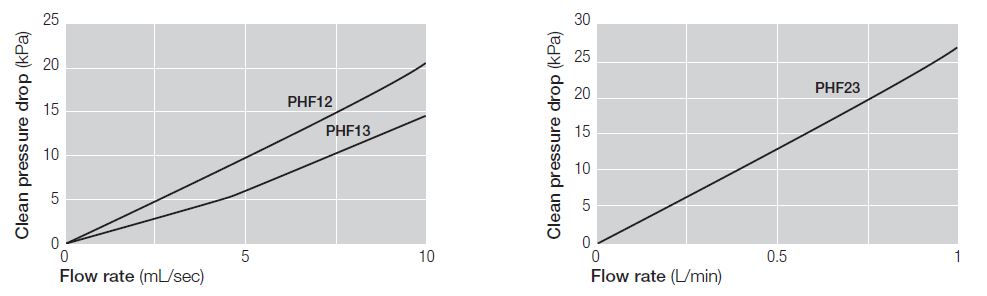

Typical Flow Characteristics - 1cP fluid, 20℃

PHF23NTD2EH11

| PhotoKleen™ NTD PHF12NTD2EH11B requires PhotoKleen™ EZD-3 head manifold |

PhotoKleen™ NTD PHF23NTD2EH11 requires PhotoKleen™ EZD head manifold |

|

|

| PhotoKleen™ EZD3 head Manifold (PHF1 Type) | PhotoKleen™ EZD head Manifold (PHYG type) |

Dummy Capsules

Part Numbers / Ordering Information

PHFC1H11B (for PhotoKleenTM EZD-2, 3 manifolds)

PHFC2H11 (for PhotoKleenTM EZD manifolds)

Specifications

Materials of Construction| Components | Materials |

| Housing | PFA |

| O-ring | Perfluoroelastomer |

| Available head manifold | PHFC1 : Fits into the PhotoKleenTM EZD2/3 manifolds PHFC2 : Fits into the PhotoKleenTM EZD manifolds |

| Hold up volume | PHFC1 : 1 mL PHFC2 : 14 mL |

| Maximum Operating Temperature | PHFC1 : 30 °C / 86 °F PHFC2 : 23 °C / 73 °F |

| Maximum Operating Pressure | PHFC1 : 0.29 MPa @ 30 °C / 42 psi @ 86 °F PHFC2 : 0.39 MPa @ 23 °C / 57 psi @ 73 °F |

We appreciate your review of this product. Please login to your account to leave a review.