Datasheets

Download:High Flow, High Capacity Pleated Polypropylene Filter Elements

- Large cartridge geometry

- High flow capacity1

- Poly-Fine® II proprietary media for highly consistent filtration

- Inside to out flow traps contaminant inside the element

- Fits into standard High Flow filter housings

1Maximum flow through the filter element is application dependent. Pall suggests not to exceed 500 gpm (1892 lpm) per 60" element; 333 gpm (1260 lpm) per 40" element; 167 gpm (632 lpm) per 20" element, as good application practice.

Product Specifications

Materials of Construction:

| Filter Medium: | Polypropylene |

| Support: | Polypropylene |

| End caps: | 10% glass fiber reinforced polypropylene |

| Center core (60" length only): | Polypropylene |

| O-ring/U-cup seal options: | Ethylene propylene, Fluorocarbon elastomer, Nitrile |

Dimensions (nominal):

| Cartridge length: | 20" (508 mm), 40" (1016 mm), 60" (1524 mm) |

| Cartridge max. OD: | 6.3" (160 mm) |

| Medium OD: | 5.9" (150 mm) |

| Medium ID: | 3.5" (89 mm) |

Particle Removal Ratings (μm)3

| Grade | ≥ 90% Removal (Beta 10) |

| PFTM1 | 1 μm |

| PFTM3 | 3 μm |

| PFTM5 | 5 μm |

| PFTM10 | 10 μm |

| PFTM20 | 20 μm |

| PFTM40 | 40 μm |

| PFTM70 | 70 μm |

| PFTM90 | 90 μm |

| PFTM150 | 150 μm |

Typical Liquid Flow Specifications

| Filter Grade | PSID per 1 GPM (mbard/lpm) - Water @ 68°F (20°C)4 | ||

| 20" | 40" | 60" | |

| PFTM1 | 0.0253 (0.4601) | 0.0126 (0.2300) | 0.0084 (0.1534) |

| PFTM3 | 0.0064 (0.1168) | 0.0032 (0.0583) | 0.0022 (0.0401) |

| PFTM5 | 0.0035 (0.0643) | 0.0018 (0.0319) | 0.0012 (0.0212) |

| PFTM10 | 0.0016 (0.0288) | 0.0008 (0.0146) | 0.0005 (0.0097) |

| PFTM20 | 0.0011 (0.0199) | 0.0006 (0.0100) | 0.0004 (0.0067) |

| PFTM40 | 0.0008 (0.0138) | 0.0004 (0.0073) | 0.0003 (0.0049) |

| PFTM70 | 0.0010 (0.0184) | 0.0005 (0.0091) | 0.0003 (0.0061) |

| PFTM90 | 0.0004 (0.0069) | 0.0002 (0.0036) | 0.0001 (0.0024) |

| PFTM150 | ‹0.0001 (‹0.0018) | ‹0.0001 (‹0.0018) | ‹0.0001 (‹0.0018) |

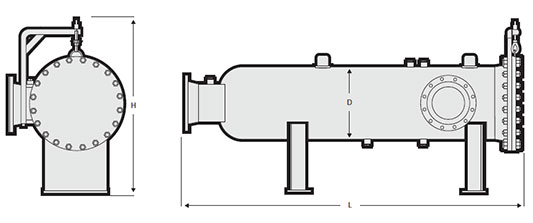

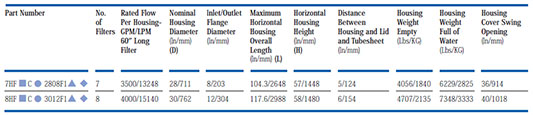

Horizontal Housings

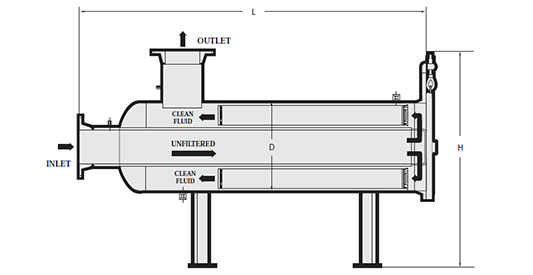

Horizontal Housings, Centerpipe Design

3Removal efficiencies based upon a modified ASTM F795 Dynamic Single Pass Efficiency test.

4Pressure drop in psid per gpm for the cartridge length shown. Multiply this value by the total system flow to determine the aqueous pressure drop. Note, for fluids other than water, multiply this value by the fluids viscosity at the operating temperature in centipoise. This value is the pressure drop across the Marksman PFT High Flow filter(s) only; it must be added to the pressure drop due to the High Flow filter housing. For kPa/lpm, multiply mbard/lpm by 0.1000.

Performance Specifications

Filter Grades:

1, 3, 5, 10, 20, 40, 70, 90, 150 micron (μm)

Maximum Operating Differential Pressure:2

50 psid (3.4 bard) @ 68°F (20°C)

35 psid (2.4 bard) @ 160°F (71°C)

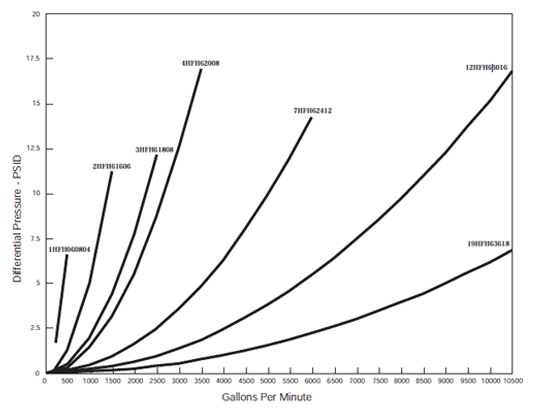

Figure 1: High Flow Horizontal Housings (Aqueous Housing Pressure Drop - PSID)

2Maximum operating differential pressure recommended for inside to out flow only.

Filter Installation and Filter Seal Mechanism

To install a filter element, remove the element hold down plate by lifting it off the locating pins. Lubricate the O-ring on the open-end of the filter with a compatible fluid, and slide the closed end of the filter into the perforated cage, which is welded to the tubesheet. Seat the elements in place by pressing down on the open-end of the filter until the element is snug in the tubesheet. This provides a seal between the filter and housing via the filter O-ring. The open-end cap must be below the tubesheet surface. After installing all the filter cartridges, reinstall and secure the element hold down plate by guiding it over the locating pins on the tubesheet. The purpose of the hold down plate is to prevent the elements from becoming dislodged in the event of reverse flow.

A filter element tool is provided with each housing to aid with the installation and removal of the filter cartridges. This tool eliminates the need for an operator to reach within the filter vessel to either remove or install the filters.

Housing Design

Three configurations are available: horizontal, vertical and centerpipe design.

The in-line horizontal configuration eliminates the need for a platform, or ladder, to remove the filters from the housing.

Vertical vessels may be more appropriate when floor space is limited. However, a platform may be needed to easily remove the elements.

In both the standard horizontal and vertical configurations, the inlet pipe is located between the filter element tubesheet and housing lid. The larger the vessel diameter, the longer the distance to reach in and remove the elements from the vessel. In a centerpipe vessel the housing lid is closer to the filter tubesheet. When the lid is opened the filters are easily accessible for installation and removal.

- Designed to the ASME, section VIII, division 1 code

- Maximum differential pressure across tubesheet: 75 psid (5.2 bar) maximum

- Standard housing gasket: spiral wound 304 stainless steel mineral fiber

- Carbon steel exterior surfaces: sandblasted and coated with an inorganic zinc

- Vent and drains: 1 inch FNPT

- Corrosion allowance: 1⁄8 inch

PFTM Table 1 - Table 2 U-HF Table 3 (e.g., PFTM3-20U-HFJ)

| Table 1 | Filter Grades |

| 1 | 1 μm |

| 3 | 3 μm |

| 5 | 5 μm |

| 10 | 10 μm |

| 20 | 20 μm |

| 40 | 40 μm |

| 70 | 70 μm |

| 90 | 90 μm |

| 150 | 150 μm |

| Table 2 | Cartridge Lengths - nominal (inches/mm) |

| 20 | 20/508 |

| 40 | 40/1016 |

| 60 | 60/1524 |

| Table 3 | Seal/O-ring Material |

| H13 | Nitrile O-ring |

| H13U | Nitrile U-cup |

| H | Fluorocarbon Elastomer O-ring |

| HU | Fluorocarbon Elastomer U-cup |

| J | Ethylene Propylene O-ring |

| JU | Ethylene Propylene U-cup |

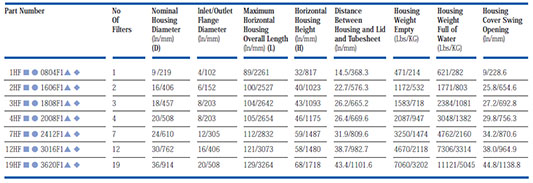

Ordering Information-Standard Horizontal and Vertical Housings

Ordering Information - Horizontal Orientation, Centerpipe Designed Housings

| ■ | Housing Configuration |

| H | Horizontal |

| V | Vertical |

| • | Nominal Cartridge Length (Inches/mm) |

| 2 | 20/508 |

| 4 | 40/1016 |

| 6 | 60/1524 |

| ▲ | Housing Metallurgy |

| 285 | Carbon Steel Vessel, 304 Stainless Steel Tubesheet |

| S3 | 304L Stainless Steel |

| S8 | 304 Stainless Steel |

| L3 | 316L Stainless Steel |

| L8 | 316 Stainless Steel |

| ♦ | Optional Outlet Size5 Horizontal Housings |

| XU | Upper Outlet Location |

| XL | Lower Outlet Location |

5 If the housing is to be used as a prefiller to a horizontal liquid/liquid coalescer, then the vessel should be ordered using the XU or XL option for the outlet location. The orientation of the outlet should be the same as that of the sump on the coalescer. In this way no buildup of coalesced liquid will occur in the prefiller.

We appreciate your review of this product. Please login to your account to leave a review.