Datasheets

Download:Profile Coreless filter elements combine Pall proven Profile depth filter technology with a design that eliminates the core to provide a convenient, cost efficient and environmentally-friendly solution for high flow rate applications.

The large diameter filter element features low differential pressure polypropylene, nylon or polyphenylene sulphide (PPS) medium, meaning fewer elements are required for a given flow rate. Filter vessels are correspondingly smaller, resulting in lower capital and installation costs, as well as reduced operating costs.

The large diameter filter element features low differential pressure polypropylene, nylon or polyphenylene sulphide (PPS) medium, meaning fewer elements are required for a given flow rate. Filter vessels are correspondingly smaller, resulting in lower capital and installation costs, as well as reduced operating costs.

Convenience

The Profile Coreless filter element fits over a 316L stainless steel core, which is retained inside the filter housing. At changeout, the element is simply pulled up over the core which is then ready to accept the replacement element. By retaining the metallic core, the Coreless design significantly reduces the amount of waste material to dispose of, providing a lower cost, more environmentally-friendly option.Efficiency

Profile Coreless filter elements use the advanced and proven benefits of Profile medium’s unique depth filter technology. The combination of a continuous graded pore prefilter section and a high performance inner section is an ideal combination, giving low clean differential pressure, high liquid flow rates and long service life.Quality

The Profile Coreless filter element is manufactured to a very high standard of quality assurance and cleanliness, and in accordance with BS EN ISO 9001:2008.Features

- Large diameter cartridge utilizing low differential pressure media.

- Separate stainless steel core retained in the filter housing.

- Proven depth filter technology / continuous graded pore structure.

- Polypropylene, nylon or polyphenylene sulphide (PPS) filter media.

- Fully disposable design.

Benefits

- Smaller systems with low capital cost, low installation costs and reduced operating costs.

- Providing high liquid flow rate capability, ease of fitment, low operating costs and increased cost efficiency.

- Reliable, consistent and verifiable filtration performance.

- Compatible with a wide range of applications.

- Less waste materials, lower cost of disposal and more environmentally-friendly

Materials of Construction

| Filter Element | Polypropylene, Nylon or Polyphenylene Sulphide (PPS) |

| Core Assembly | 316L Stainless Steel |

Technical Information

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure | Operating Temperature | ||

| Polypropylene | Nylon | Polyphenylene Sulphide (PPS) | |

| 4.0 bard (58 psid) | 32 °C (89.6 °F) | 32 °C (89.6 °F) | 32 °C (89.6 °F) |

| 1.0 bard (14.5 psid) | 82 °C (179.6 °F) | 130 °C (266 °F) | 204 °C (400 °F) |

1Compatible fluids are defined as those which do not swell, soften or attack any of the filter components

Core Assembly Seals (removable option only)

| Seal Material |

| Ethylene Propylene Rubber (EPR) |

| Fluorocarbon Elastomer |

| FEP encapsulated Fluorocarbon Elastomer |

| Nitrile |

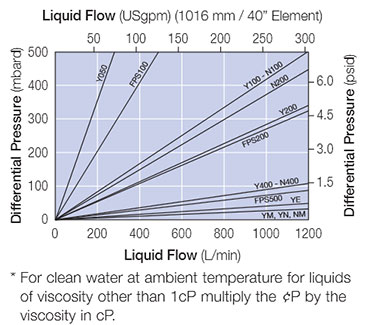

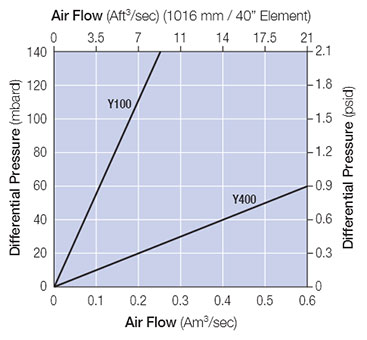

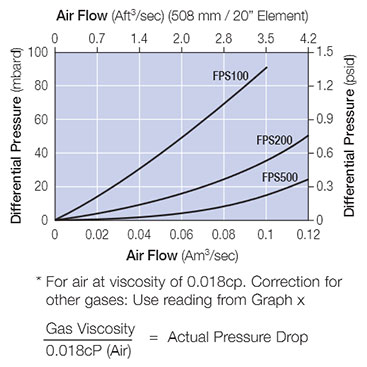

Flow Rates

Large Format Filters

Operating and Installation Procedures - Profile® Coreless Filter Element  FP01109 Rev. A.

FP01109 Rev. A.

Operating and Installation Procedures - Pall® Coreless Filter Assembly ![]() L00648

L00648

This information is a guide to the part number structure and possible options. For availability of specific options, please contact Pall. Refer to Pall for housing details.

Element Part Number: E 60 [1] [2]

Core Assembly (removable option) Part Number: EHS 60 [1] [3]

2 Beta 5000

Element Part Number: E 60 [1] [2]

Core Assembly (removable option) Part Number: EHS 60 [1] [3]

Table 1: Nominal Length

| Code | Description |

| 2 | 508 mm (20") |

| 4 | 1016 mm (40") |

Table 2: Media Options

| Polypropylene2 | Nylon2 | Polyphenylene3 Sulphide (PPS) | Removal Rating in Liquids (μm) | Removal Rating in Gases at 0.3 μm4 |

| Y050 | — | — | 5 | — |

| Y100 | N100 | FPS100 | 10 | 99.997 % (Y100) 99.999 % (FPS100) |

| Y200 | N200 | FPS200 | 20 | — |

| Y400 | N400 | — | 40 | 99.995 % (Y400) |

| — | — | FPS500 | 50 | 99.869 % (FPS500) |

| YE5 | — | — | Coarse grade media for use in E-coat paint baths | |

| YM5 | NM | — | Coarse grade media for use in mica paint applications | |

| YN5 | — | — | Coarse grade media for use in mica paint applications | |

2 Beta 5000

3 Beta 1000 efficiency rating

4 Determined in laboratory trials using sodium chloride aerosols at 300 Sm3 / hr

5 Profile Coreless paint application filter elements are not given removal ratings

Replacement Core Assembly Seals

| O-ring Seal | Part Number |

| Ethylene Propylene Rubber (EPR) | CA53418 and ORJPW-111P |

| Fluorocarbon Elastomer | LS00372 and LS00429 |

| FEP encapsulated Fluorocarbon Elastomomer | CC62592 and CC62591 |

| Nitrile | LS0043 and LS543 |

We appreciate your review of this product. Please login to your account to leave a review.