Datasheets

Download:Continuous Length, Backflushable, Precoat, Condensate Filter

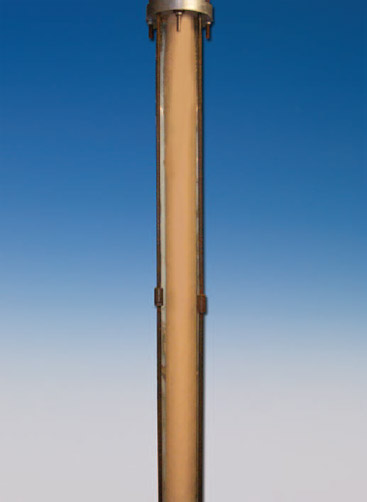

Hydro-Guard CoLD R filter elements are manufactured using the CoLD Melt™ fiber production process. The CoLD Melt process permits the creation of multiple filtration zones within a single filter cartridge. The reverse graded pore density, multi-zone design provides customers with even precoating, efficient backflushing, and long filter life. Many power plants around the world have switched from string wound technology to Hydro-Guard CoLD R products for improved condensate polishing.

| Product Feature | Product Benefit | Customer Benefit |

| Continuous Length Element |

|

|

| Co-Located Large Diameter Melt Fibers |

|

|

| Reverse Graded Pore Density Structure |

|

|

| All Polypropylene Construction |

|

|

Performance Specifications

Maximum operating temperature

65 °C (150 °F)

Maximum differential pressure

2.07 bard (30 psid) @ 65 °C (150 °F)

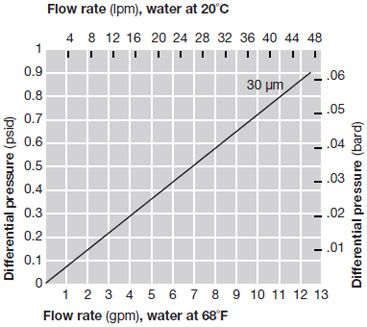

Typical Flow vs. Differential Pressure for Application Sizing1

Unit conversion: 1 bar = 14.5 psi

1 Flow rate is for a 152 cm/60 inch 30 μm cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Product Specifications

Materials of construction

| Filter media: | Polypropylene |

| End caps: | Polypropylene |

| Sealing: | Thermal bond |

| Gasket/O-ring material: | Sulfur-free EPDM (standard) |

Filter Cartridges

Pall Part Number = HGCOLDR [1]-[2]-P-[3]-[4]-[5]

Table 1

| Code | Filter grades (μm) |

| 5 | 5 |

| 30 | 30 |

Table 2

| Code | Cartridge lengths cm/in. |

| 50 | 127/50 |

| 60 | 152/60 |

| 70 | 178/70 |

| 80 | 203/80 |

Table 3

| Code | Seal material |

| E | Sulfur-free EPDM |

Table 4

| Code | End configurations - bottom |

| COOP | Fine threaded connection for bottom tube sheet vessels |

| M8TVO | Extended neck, double O-ring seal for top tube sheet vessels |

| PAK-F | One turn, easy install/remove connection with double seal integrity for bottom tube sheet vessels |

| PBQ | Double-open-end filter for bottom tube sheet vessels |

End configurations - bottom

Table 5

| Code | End configurations - top |

| H | 3& ⁄8 HEX - 2.5 inch elongated hex nut and cotter pin for connection with vessel lattice strips |

| S | 3& ⁄8 STUD - 1.5 inch threaded stud and either nut or cotter pin for connection with vessel lattice strips |

| FIN | SPEAR - Bottom retaining devise for top tube sheet filters |

| DOE | Double-open-end filter for top tube sheet vessels |

End configurations - top

We appreciate your review of this product. Please login to your account to leave a review.