The modular design consists of individual thin film composite membranes supported by 'o' rings between hydraulic cover disks, stacked, and assembled about a center tension rod and effectively sealed between metal end flanges. The proven open channel design provides a fully turbulent flow, high permeate recovery and reduced membrane fouling.

Disc Tube Module Operation

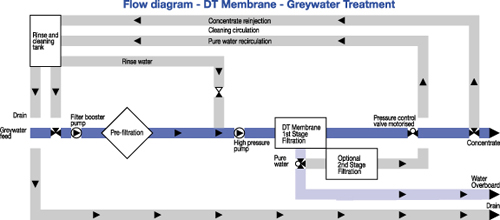

Greywater flows down passages between the disc stack and the pressure vessel and enters the flow chamber from beneath the bottom disk. The flow is directed up and over each membrane cushion allowing pure water to pass through the porous membrane and be collected by the permeate collector. Feedwater contamination is prevented by "O" ring seals fitted to the hydraulic disks. As the pure water is removed the concentrate can be treated further, held in a collection tank or incinerated.

Flow Diagram

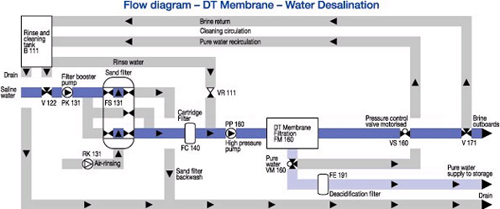

Flow Diagram

The Pall Disc Tube™ Module System is a major advance in Reverse Osmosis technology. The fluid dynamics and construction of the disc membrane stack result in an open channel, unrestricted and fully turbulent feedwater system. This means that suspended solids carried in the feedwater cannot be trapped or easily settle out inside the membrane module. In frequent maintenance, cleaning of the membranes can be successfully achieved using a standard, built-in system. Round-the-clock reliability and product water quality are also guaranteed. These are achieved through Pall's adherence to the highest standards in components, materials, and methods of design and construction. Advantages of the Disc Tube Module System include:

- Minimization of membrane scaling and fouling. The system uses short feed flow paths, open channels and high-packing densities to minimize concentration polarization and physical flow impediments. Consequently, scaling and fouling are greatly reduced while high energy efficiency is maintained.

- Long membrane life. The combination of low membrane scaling and fouling, highly stable membranes, and the simple built-in cleaning system means that membrane life-expectancy is not normally limited by feedwater pollution. Useful membrane life of five years or more can be expected.

- Lower membrane replacement costs. Compared to spirally wound and hollow fiber membrane elements which are life-sealed at manufacture (so the complete element must be replaced at relatively high cost), the DT Module system allows the replacement of individual sheets of membrane at a fraction of the cost.

- Easy access to all membranes. Modules can easily be opened up to permit replacement or inspection of each membrane cushion.

- Fail-safe unattended operation. The only moving parts are the pumps and all operating functions are automatically controlled and fail-safe. No special skills are required to operate the system.

- Compact and flexible. Modular design and construction of all standard units simplifies transportation and installation, and enables efficient use of floor space.

Membrane Module |

Originally designed to produce drinking water from sea water, Disc Tube technology is now being successfully applied to other markets such as leachate, petroleum contaminated water, and industrial wastewater streams.

In addition to RO membrane systems, DT technology can also be used in conjunction with microfiltration, nanofiltration, and ultrafiltration membrane systems. DT systems also allow the use of wastewater as a demineralize feeder while extending demineralizer run length tenfold. |

We appreciate your review of this product. Please login to your account to leave a review.