Supradisc™ II Modules

The Next Generation in Depth Filter Module Technology

Constantly increasing process demands in the Biopharmaceutical industry has driven Pall Corporation to develop the Supradisc II PP depth filter module. The Supradisc II design combines the filtration performance of Seitz® media and the structural robustness of interlocking dual drainage plates. This provides the most robust design available in the market today. The dual drainage plate design of the Supradisc II PP depth filter module optimizes the flow distribution by providing unobstructed process flow. These advancements in module design also enhance module integrity as well as superior resistance to back pressure failures of the filter media.

Documents

Description

The Next Generation in Depth Filter Module Technology

Constantly increasing process demands in the Biopharmaceutical industry has driven Pall Corporation to develop the Supradisc II PP depth filter module. The Supradisc II design combines the filtration performance of Seitz® media and the structural robustness of interlocking dual drainage plates. This provides the most robust design available in the market today. The dual drainage plate design of the Supradisc II PP depth filter module optimizes the flow distribution by providing unobstructed process flow. These advancements in module design also enhance module integrity as well as superior resistance to back pressure failures of the filter media.

Pall SUPRAdisc II features

- Interlocking and welded drainage plates provide similar structural integrity as found with most filter cartridge cage and core assemblies

- Highest structural robustness due to dual drainage plates

- Filter media is less susceptible to blinding from media-to-media contact within the module assembly

- Unobstructed process flow

- Optimized flow distribution upstream and downstream of the filter sheets maximizes filter utilization

- Fully supported filter sheets inhibit the rupturing of filter media frequently associated with back pressure

- Shipping and handling damage is significantly reduced through the very same interlocking and welded drainage plates

- Highest packing density minimizes hold up volume

- Supradisc II modules are steam sterilizable at 125°C for 30 minutes

- All plastic components used in construction meet the specifications for the biological test listed in the current version of the USP Class VI 121°C

- Supradisc II PP depth filter module and all its components are fully traceable by serial number

High Quality and FDA Conformity

The filter sheets meet the specifications set forth in the US Code of Federal Regulations Title 21, parts 177.2260 e, f, g, h, i, j, k, l. The materials for all plastic components are listed in US Code of Federal Regulations Title 21, part 177.1520.

With regard to food law conformity, the manufacture of depth filter sheets is also subject to ongoing analysis by the German ISEGA Forschungs- und Untersuchungsgesellschaft mbH, Aschaffenburg.

Technical Service

For best possible support and maximum reliability, we recommend performing filter evaluations utilizing your process and process conditions. Pall’s specialists can provide valuable support, either at your facility or in our SLS (Scientific and Laboratory Services) laboratories, providing hands-on assistance and placing its extensive technical resources at your disposal in the form of worldwide technical advice, including problem solving, process review and cost reduction programs.

Further Information

Further information is available on Pall's range of Filter Modules and Capsules with Seitz Depth Filter Media.

Specifications

Operating Characteristics*

| Maximum Operating Temperature | 80 °C |

| Maximum Operating Pressure | 2.4 bard (35 psid) |

* With compatible fluids, which do not soften, swell or adversely affect the products or its material of construction.

Materials of Construction

| Pall Supradisc II Components | Polypropylene |

| O-rings | Platinum cured silicone elastomer |

Sterilization

| Steam in Place | 125 °C for 30 minutes at 0.3 bard (4.3 psid) maximum |

Nominal Dimensions

Total Length: |

|

| Total Diameter | 284 mm (12 in.) in 232 design 410 mm (16 in.) in 440 design |

| Filter Area | 1.8 m2 (19.4 ft2) in 232 design |

Filter Media Specification

| Code | Depth Filter Type | Typical Water Permeability in L/min/m2 @ Δp 1 bar (14.5 psid) |

Nominal Retention Rating in µm | Ash Content in % | Endotoxin Level in EU/mL before Rinsing |

|---|---|---|---|---|---|

| PEKS | EKSP | 29 | 0.1-0.3 | 58 | <0.06 |

| PEKM | EKMP | 41 | 0.2-0.5 | 48 | <0.06 |

| PEK1 | SUPRA EK1P | 64 | 0.2-0.5 | 47 | <0.06 |

| P050 | KS 50P | 93 | 0.4-0.8 | 46 | <0.06 |

| P080 | SUPRA 80P | 159 | 1.0-3.0 | 49 | <0.06 |

| P100 | K100P | 149 | 1.0-3.0 | 45 | <0.06 |

| P200 | K200P | 217 | 3.0-6.0 | 43 | <0.06 |

| P250 | K250P | 535 | 4.0-9.0 | 44 | <0.06 |

| P700 | K700P | 935 | 6.0-15.0 | 45 | <0.06 |

| P900 | K900P | 1980 | 8.0-20.0 | 45 | <0.06 |

| B010 | BIO 10 | 30 | 0.2-0.4 | <1 | <0.06 |

| B020 | BIO 20 | 75 | 0.4-1.0 | <1 | <0.06 |

| XEK1 | EK1 | 41 | 0.2-0.4 | 51 | NA |

| XEK | EK | 68 | 0.3-0.5 | 46 | NA |

| X050 | KS50 | 93 | 0.4-0.8 | 46 | NA |

| X080 | KS80 | 113 | 0.6-2.0 | 46 | NA |

| X100 | K100 | 146 | 1.0-3.0 | 46 | NA |

| X150 | K150 | 185 | 2.5-4.0 | 46 | NA |

| X200 | K200 | 213 | 3.0-6.0 | 46 | NA |

| X250 | K250 | 510 | 4.0-9.0 | 46 | NA |

| X300 | K300 | 785 | 5.0-12.0 | 46 | NA |

| X700 | K700 | 925 | 6.0-15.0 | 46 | NA |

| X900 | K900 | 1700 | 8.0-20.0 | 46 | NA |

| T950 | T950 | 1700 | 8.0-20.0 | 40 | NA |

| T100 | T1000 | 3400 | 10-25 | 35 | NA |

| T150 | T1500 | 7285 | 11-30 | 33 | NA |

| T210 | T2100 | 10200 | 13-35 | 13 | NA |

| T260 | T2600 | 10200 | 15-40 | <1 | NA |

| T350 | T3500 | 12750 | 19-50 | 13 | NA |

| T550 | T5500 | 25500 | 25-70 | <1 | NA |

NA - Not Applicable as endotoxin content is not a measured criteria for these sheets.

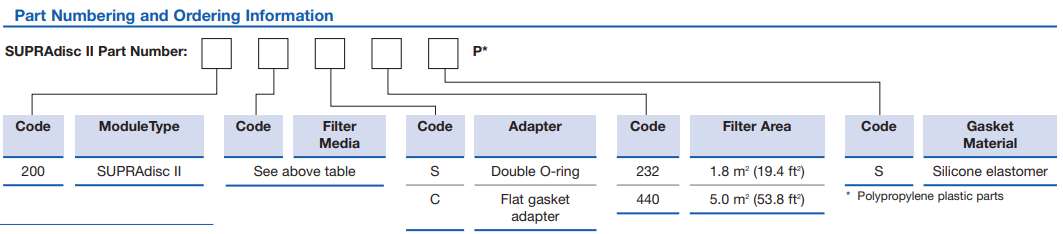

Ordering Information

Pall SUPRAdisc II Depth Filter Modules

Please talk to Pall representative regarding your requirements so we can provide a suitable product for your application.