Datasheets

Download:Large-Capacity Capsule Filters for Ink Jet Ink Filtration and Critical Printhead Protection On Larger Digital Printing Systems

The DFAC filter capsule is a large-capacity, self-contained filter developed for larger digital printing systems that require increased ink flow rates.This filter capsule extends the capabilities of the DFA capsule with new features specifically for the digital printing market.

Among these features is an opaque exterior shell to protect against UV-light intrusion, large-bore connections to minimize pressure loss, and a wide range of industry-accepted media appropriate for most digital printing applications.

Two capsule sizes are available, with twice and four times the capacity of the popular Multiple Application Capsule (MAC).

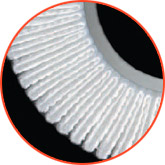

Filter media offerings include Profile® Star media and HDC® II media in six grades, with ratings from 3 μm to 20 μm.

Features

- Compact assembly with high flow capacity filter

The DFAC filter capsule features both a compact assembly and a pleated filter with high flow capability. This is a critical combination in high-flow recirculating ink systems, where consistent flow rates are required for accurate jetting. - Opaque capsule

The black polypropylene exterior housing protects against UV light and prevents ink from curing inside the filter. This capsule is also suitable for ink chemistries that are not UV curable. - Key media options for digital printing

Profile Star and HDC II filter media are available. Profile Star media is an industry standard, with excellent gel-retention capability and long life. HDC II media has a pleated, high-area design with excellent flow rates. - Easy change large-bore connections

Large-bore inlet and outlet connections are present in both size capsules to minimize pressure loss. The standard connections are Swagelok*-compatible compression fittings, with available 6 mm and 8 mm connections. - Venting capability

The heavy-duty, compression-fitting vents allow for venting at start-up (recommended) or periodic venting as needed, or serve as connections for continuous venting, if required. - All-polymeric construction

The all-polypropylene construction of the filter capsule makes it suitable for use with most ink jet ink formulations.

*Swagelok is a trademark of Swagelok Company.

| Features | Advantages | Value |

| Filter media consistent with other Pall ink jet capsules | Seamless scale-up with industry-accepted filter media | Fewer transition issues when developing new printer platforms |

| Rugged Swagelok-compatible compression-fitting connections | Easy and quick filter change; no fitting change required | Minimal ink loss and printer downtime |

| Binders, glues, and mold release agents not used | Low extractables from filter components | No changes to ink properties from additional materials |

| Compact capsule with minimal dead space | Rapid capsule priming at start-up | Reduced ink loss and printer downtime |

| Rugged, molded-in vent connections | Able to vent quickly at start-up and/or continuously during operation | Virtually eliminates air entrapment during operation |

| Materials of Construction | |

| Filter media | Polypropylene |

| Core and endcaps | Polypropylene |

| Housing | Polypropylene with a carbon black colorant |

| Operating Conditions1 | |

| Maximum allowable pressure | 4.1 bar / 60 psi @ 38 °C / 100 °F |

| Maximum allowable temperature | 50 °C / 122 °F |

1 Fluids that do not soften, swell or adversely affect the filter or materials of construction.

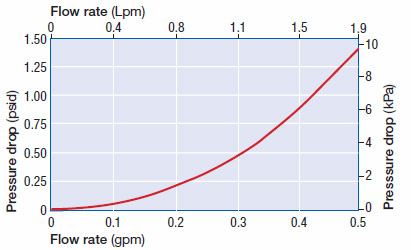

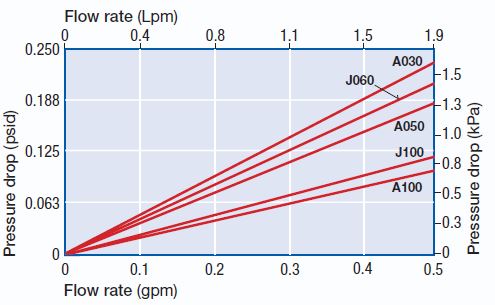

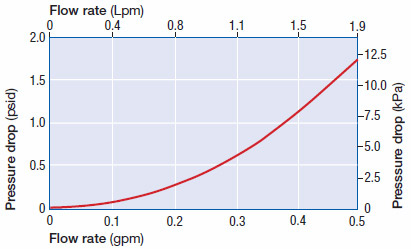

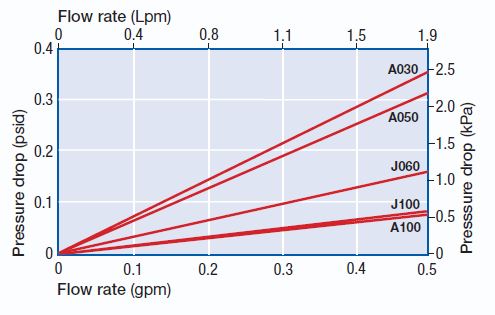

Typical Liquid Flow Rate vs Differential Pressure

To approximate differential pressure, add the values for capsule pressure drop and module pressure drop for the selected media grade. For liquids with higher viscosities than water, multiply the module pressure drop by the viscosity in centipoise before adding the capsule pressure drop.DFAC1 Capsule Pressure Drop in Water

DFAC1 Module Pressure Drop in Water

DFAC2 Capsule Pressure Drop in Water

DFAC2 Module Pressure Drop in Water

Filter Capsules

Operating and Installation Procedures ~ Pall Industrial Capsule Assemblies

Dimensions

DFAC1 Capsule

Filter Media Options

| Profile® Star Media | HDC® II Media |

|

|

Ordering Information / Part Numbers2

DFAC1 Capsules

Opaque capsules with 6 mm Swagelok-compatible inlet and outlet connections and 4 mm Swagelok-compatible vents and drains. Individually bagged and bulk packaged (48 per case).| Part Number | Removal Rating3 |

| Profile Star Media | |

| DFAC5301A030 | 3 μm |

| DFAC5301A050 | 5 μm |

| DFAC5301A100 | 10 μm |

| DFAC5301A200 | 20 μm |

| HDC II Media | |

| DFAC5301J060 | 6 μm |

| DFAC5301J100 | 10 μm |

DFAC2 Capsules

Opaque capsules with 8 mm Swagelok-compatible inlet and outlet connections and 4 mm Swagelok-compatible vents and drains. 1/4" PLC Quick Connect inlet and outlet connections and Luer Lock vents and drains (5 μm only) Individualy bagged and bulk packaged (24 per case)

| Part Number | Removal Rating3 |

| Profile Star Media | |

| DFAC2A030SW84M | 3 μm |

| DFAC2A050SW84M | 5 μm |

| DFAC2A050PLC4L0 | 5 μm |

| DFAC2A100SW84M | 10 μm |

| DFAC2A200SW84M | 20 μm |

| HDC II Media | |

| DFAC2J060SW84M | 6 μm |

| DFAC2J100SW84M | 10 μm |

2 This is a guide to the part numbering structure only. For availability of specific options, please contact your local Pall representative.

3 The removal ratings in this publication are based on the modified OSU-F2 test. Please contact your Pall representative for additional information.

We appreciate your review of this product. Please login to your account to leave a review.