Operating Conditions

Operating temperature and maximum differential pressures in compatible fluids.1

| Operating Temperature |

Maximum Differential Pressure |

| 82 °C / 180 °F |

1 bard / 15 psid |

| 70 °C / 158 °F |

2 bard / 30 psid |

| 30 °C / 86 °F2 |

4.1 bard / 60 psid |

1 Fluids that do not soften, swell or adversely affect the filter or materials of construction.

2 Recommended filter changeout: 2.3 bard / 40 psi.

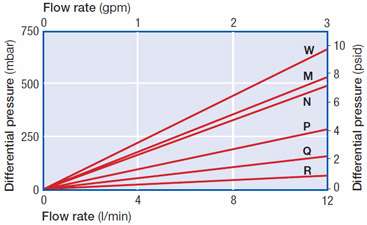

Typical Liquid Flow Rate versus Differential Pressure3

3 For liquids with viscosities differing from water, multiply the pressure drop by the viscosity in cP.

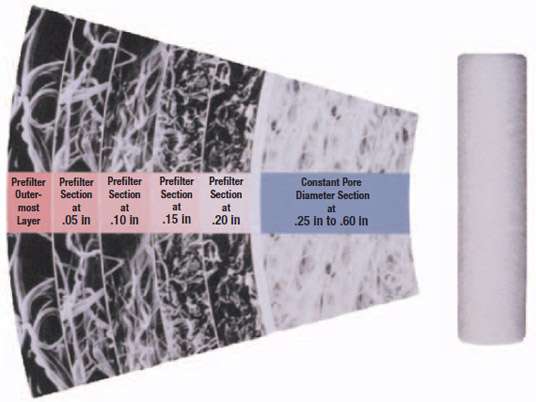

Figure 1 Graded pore structure