With Pall’s Coralon™ hydraulic and lube oil filter elements, protecting fluid systems has never been easier!

A simple and risk-free upgrade that does not require any adapters or special tools and is directly interchangeable with the current Ultipor® filter installations, Coralon lube oil filters and hydraulic fluid filters are the ideal solution for those looking to achieve optimum performance and yield at lesser costs.

Benefits of switching to Coralon filter elements:

- Upgraded filtration with Stress Resistant Media Technology (SRT) at no extra cost

- Proven improved performance, irrespective of age or condition

- Reduced equipment operating costs

- Fluid and temperature compatibility

- Optimum performance in equipment protection; increase equipment output

- Anti-static, greatly reducing static charge build-up

- Cost reduction of up to 20%

- These hydraulic and lube oil filter elements produce up to 15x cleaner fluids and have 16x more consistent performance throughout the filter’s service life.

Why Choose Pall’s Coralon Filter Elements?

Overcoming the challenges faced in lube and hydraulic fluid applications, Pall’s Coralon filters provide an easy and advanced upgrade in oil filter media. These hydraulic fluid filter elements deliver improved and consistent performance that protect fluid systems while producing up to 15x cleaner fluids, and returning up to 20% savings in overall filtration costs.

Pall’s Coralon (anti-static) hydraulic oil filter elements provide:

- Consistent, high particle capture efficiency (high dirt-holding capacity)

- Low pressure drop for small envelop size and longer life

- Added benefit of significantly reduced static charge generation

- Optimum performance even under system stresses throughout the duration of the filter life, and;

- Production of consistently cleaner liquid

Overall, there is no drop in filter performance or efficiency, until the filter is blocked. And when the filter gets blocked, it indicates that the contaminants are in the filter rather than in the machines, all of which add up to improved equipment performance and longevity.

Coralon anti-static filters also eliminate problems related to electrostatic charging and its effects, such as:

- Noise, sparking, component and filter damage

- Varnish formation

- Charge generated by housings and pipes

- Excess electrostatic charge created by standard glass and paper media.

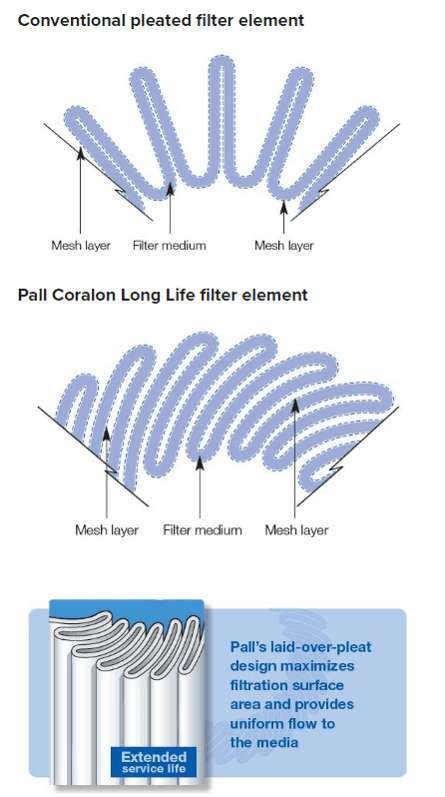

Advanced Lube and Hydraulic Fluid Filter Element Design

Coralon hydraulic and lube oil filter elements incorporate Pall’s advanced filter medium pack construction that benefits from Stress-Resistant filter medium Technology (SRT) along with,

- blended layers of fiberglass

- optimized construction for low differential pressure and stress resistance

- tapered pore construction

- uniform pore size control layer and

- epoxy resin bonded fiber structure.

Coralon Filter Performance

The effectiveness of a filter in an operating system reduces due to conditions such as varying flow, cold starts, shock and vibration.

The Cyclic Stabilization Test (based on SAE ARP4205) examines the effects of cyclic flow conditions and the potentiality of the capture and retention characteristics of the filter in retaining dirt and contaminants. The result showed an improved filter performance reporting method, that simply tells the user via ISO Codes, the level of contamination control that can be maintained throughout the filter’s service life. *

A critical measure of a filter’s performance is its ability to sustain fluid cleanliness throughout its service life. Only Coralon filters have proven to produce sustained fluid cleanliness over the filter’s full life, compared to Ultipor® filters.