Order Products

Segments

Beer (Corporate)

Emflon® PFRW Filter Cartridge, AB05PFR2WH4

1/EA

1

Emflon® PFRW Filter Cartridge, AB1PFR7WH4

1/EA

1

Claris® Filter Cartridge, CLR530W480

12/EA

12

Palltronic® Compact Touch External Power Supply, CT001-EXTPWR

1/EA

1

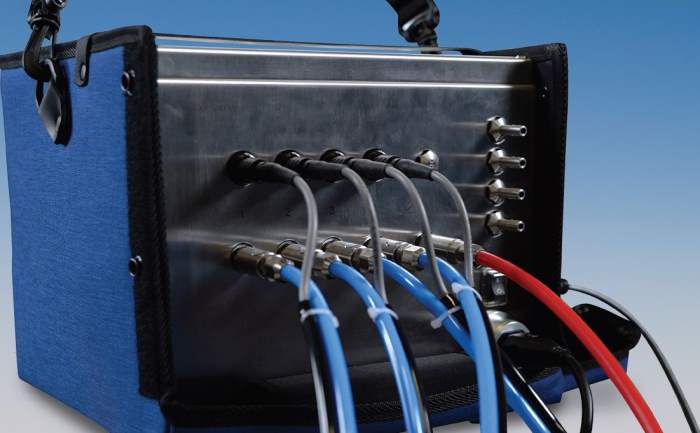

Palltronic® Blue Pneumatic Tubing (3m) with Stäubli fittings and vent valve (connects Compact Touch to test housing)

1/EA

1

Palltronic® Red Pneumatic Tubing (2m) with Stäubli fittings, CT001-INTUBING

1/EA

1

Palltronic® Compact Touch Thermal Printer Paper, CT001-PRTPAPER

1/EA

1

1/EA

1

SUPRAdisc SD II 50 200X050C440SPW

1/EA

1

SUPRAdisc SD II EK 200XEK0C440SPW

1/EA

1