Poly-Fine® II Series Pleated Filter Cartridges

A Cost-Effective Choice for Final Particle Removal and Pre-filtration in Liquids, Air and Gas - Including Reliable Protection of Final Membrane Filters

The Poly-Fine II pleated filter cartridge element is a high area, all-polypropylene depth filter cartridge frequently used in a wide variety of applications. These filter cartridges have broad chemical capability and are constructed of ultra-thin, proprietary melt-blown filter media that is intended for particle removal, excluding oils.

Poly-Fine® II Series Pleated Filter Cartridges

Description

Why choose Poly-Fine II pleated filter cartridges?

The highly consistent pore structure with narrow pore size distribution and removal ratings ranging from 0.2 to 100 µm makes these filter cartridges ideal for capturing non-deformable contaminants, particularly those characterized by limited particle distribution.

Additional benefits include:

- All polypropylene one-piece construction (except 0.2 µm)

- Constructed from proprietary melt blown, pleated media

- High dirt holding capacity

- Long service life

Applications

| Industry | Application | Examples of Use |

|---|---|---|

| Chemical and Polymers | Final product Amine, Benfield and other solid loops Carbon fiber production |

|

| Food and Beverage | Prefiltration Air, gas and vent filtration |

|

| Oil and Gas | Upstream Midstream |

|

Specifications

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Quality

- Cartridges produced in a controlled environment

- Manufactured within a Quality Management System certified to ISO 9001:2015.

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Particle Retention (µm) for Chemical and Polymer, and Oil and Gas Applications

| Liquid Service (by ASTM F-795 Test) |

Gas Service | ||

|---|---|---|---|

| Cartridge Designation |

90% Efficiency |

>99.9% Efficiency |

Removal Efficiency By DOP Test |

| PFT 0.2 | 0.2 | 0.5 | 99.99% |

| PFT 0.25 | 0.25 | 1.0 | 99.97% |

| PFT 0.45 | 0.45 | 1.2 | 99.93% |

| PFT 0.8 | 0.8 | 2.5 | 99.90% |

| PFT 2.0 | 2 | 5 | - |

| PFT 3.0 | 3 | 7 | - |

| PFT 5.0 | 5 | 12 | - |

| PFT 10.0 | 10 | 15 | - |

| PFT 30.0 | 30 | 40 | - |

| PFT 50.0 | 50 | 65 | - |

| PFT 100.0 | 85 | 100 | - |

Table 1: Removal Rating1 for Food and Beverage Applications

| Description | ||

| Code | 90% Efficiency (Beta 10) | >99.9% Efficiency (Beta 1000) |

| 0.25 | 0.25 µm | 1 µm |

| 045 | 0.45 µm | 1.2 µm |

| 08 | 0.8 µm | 2.5 µm |

| 2 | 2 µm | 5 µm |

| 3 | 3 µm | 7 µm |

| 5 | 5 µm | 12 µm |

| 10 | 10 µm | 15 µm |

| 30 | 30 µm | 40 µm |

1Poly-Fine II filter cartridge liquid retention ratings are determined by a single pass test based on ASTM F-795 (see Pall Technical Bulletin 1903-4T). Removal efficiencies are shown at the stated rating in compatible fluids.

Operating Characteristics2

| Maximum Differential Pressure3 | Operating Temperature |

|---|---|

| 4.8 bard (70 psid) (forward) | 20 °C (68 °F) |

| 2.8 bard (40 psid) (forward) | 65 °C (150 °F) |

2Fluids which do not swell, soften, or adversely affect any of the filter components.

3Recommended change-out differential pressure is 2.4 bard (35 psid), provided the maximum differential pressure (based on temperature) is not exceeded.

PERFORMANCE

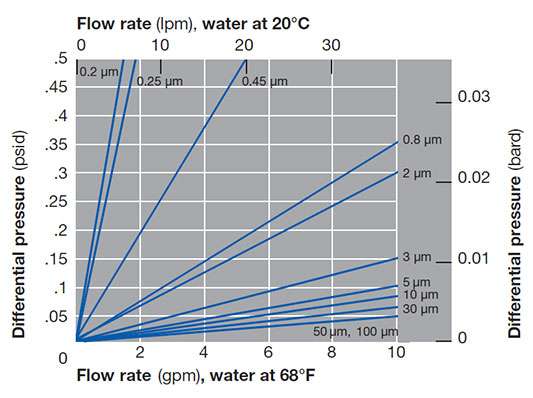

Typical Flow Rates4 for Chemical and Polymer, and Oil and Gas Applications

Typical Flow vs. Differential Pressure for Application Sizing

Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Typical Flow Rates for Food and Beverage Applications

4Typical initial clean delta p per 254 mm (10 inch) cartridge, water at 20° C (68° F). For liquids with viscosity greater than 1cP, multiply the delta p by the viscosity.