Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Quality

- Cartridges produced in a controlled environment

- Manufactured within a Quality Management System certified to ISO 9001:2015.

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Particle Retention (µm) for Chemical and Polymer, and Oil and Gas Applications

| |

Liquid Service

(by ASTM F-795 Test) |

Gas Service |

Cartridge

Designation |

90%

Efficiency |

>99.9%

Efficiency |

Removal Efficiency

By DOP Test |

| PFT 0.2 |

0.2 |

0.5 |

99.99% |

| PFT 0.25 |

0.25 |

1.0 |

99.97% |

| PFT 0.45 |

0.45 |

1.2 |

99.93% |

| PFT 0.8 |

0.8 |

2.5 |

99.90% |

| PFT 2.0 |

2 |

5 |

- |

| PFT 3.0 |

3 |

7 |

- |

| PFT 5.0 |

5 |

12 |

- |

| PFT 10.0 |

10 |

15 |

- |

| PFT 30.0 |

30 |

40 |

- |

| PFT 50.0 |

50 |

65 |

- |

| PFT 100.0 |

85 |

100 |

- |

Table 1: Removal Rating1 for Food and Beverage Applications

| Description |

| Code |

90% Efficiency (Beta 10) |

>99.9% Efficiency (Beta 1000) |

| 0.25 |

0.25 µm |

1 µm |

| 045 |

0.45 µm |

1.2 µm |

| 08 |

0.8 µm |

2.5 µm |

| 2 |

2 µm |

5 µm |

| 3 |

3 µm |

7 µm |

| 5 |

5 µm |

12 µm |

| 10 |

10 µm |

15 µm |

| 30 |

30 µm |

40 µm |

1Poly-Fine II filter cartridge liquid retention ratings are determined by a single pass test based on ASTM F-795 (see Pall Technical Bulletin 1903-4T). Removal efficiencies are shown at the stated rating in compatible fluids.

Operating Characteristics2

| Maximum Differential Pressure3 |

Operating Temperature |

| 4.8 bard (70 psid) (forward) |

20 °C (68 °F) |

| 2.8 bard (40 psid) (forward) |

65 °C (150 °F) |

2Fluids which do not swell, soften, or adversely affect any of the filter components.

3Recommended change-out differential pressure is 2.4 bard (35 psid), provided the maximum differential pressure (based on temperature) is not exceeded.

PERFORMANCE

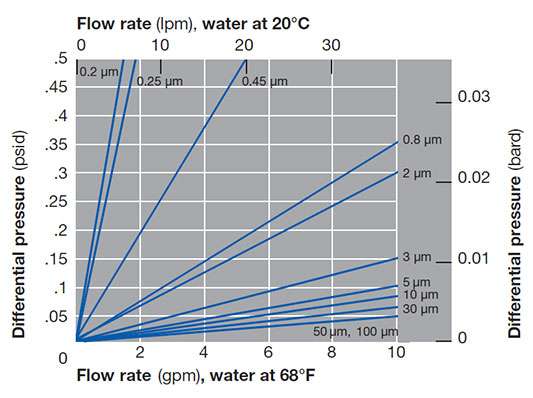

Typical Flow Rates4 for Chemical and Polymer, and Oil and Gas Applications

Typical Flow vs. Differential Pressure for Application Sizing

Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Typical Flow Rates for Food and Beverage Applications

4Typical initial clean delta p per 254 mm (10 inch) cartridge, water at 20° C (68° F). For liquids with viscosity greater than 1cP, multiply the delta p by the viscosity.