Effectively Separate Liquid/Liquid Dispersions on Medium, Coarse, or Higher Solids Emulsions

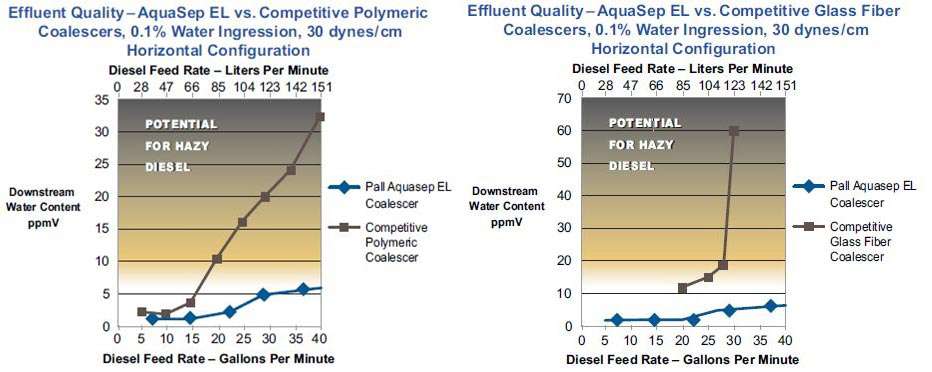

The AquaSep EL system is a multiple-stage system starting with filtration to remove particulate matter, followed by either a one-stage horizontal coalescer or a two-stage integrated vertical coalescer/separator stack to separate the two liquid phases. AquaSep EL coalescers will remove free water to a level as low as 15 ppmv1 and be effective over a wide range of conditions such as inlet liquid contaminant concentration as high as 10% and interfacial tension less than 20 dynes/cm.

Table 1: Coalescer Selection Guide

| Process Condition |

Recommended Product |

| The dispersed phase fluid is aqueous and a horizontal footprint is acceptable |

AquaSep EL coalescer in a horizontal housing without separator |

| The dispersed phase fluid is oil and the continuous phase fluid is aqueous |

| The dispersed phase fluid is aqueous and minimal footprint is required |

AquaSep EL coalescer/separator stack in a vertical housing |

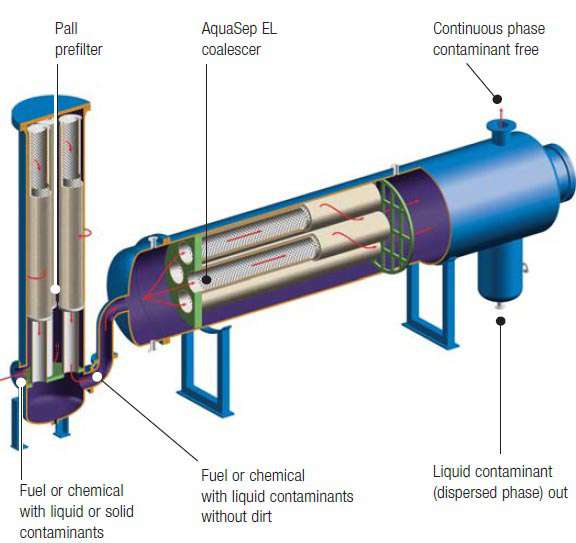

AquaSep EL Coalescer— Horizontal Housing Configuration

In a horizontal housing, the liquid/liquid mixture enters the coalescing element and flows inside-to-outside, small liquid dispersed phase droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the AquaSep EL coalescer. The large coalesced droplets of the dispersed phase separated by gravity in the horizontal housing and are removed. The size of the housing is a function of the flow rate, IFT, viscosity, and specific gravity of the liquids.

Figure 3: AquaSep EL Liquid/Liquid Separation System with Coalescer in a Horizontal Housing with a Prefilter

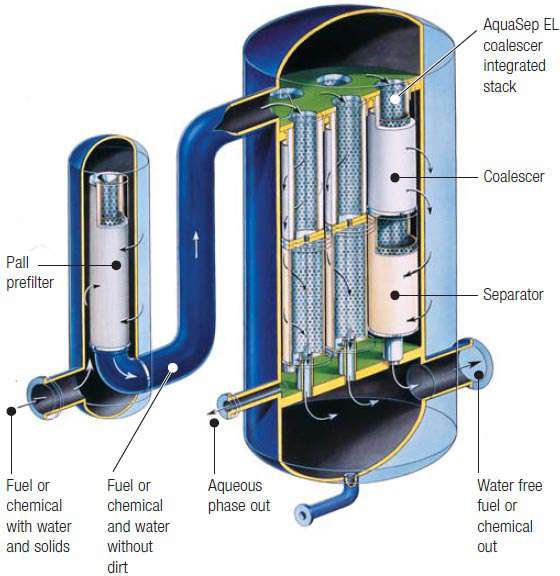

AquaSep EL Coalescer/Separator Stack— Vertical Housing Configuration

The liquid/liquid mixture enters the coalescing element and flows inside-to-outside. Small liquid droplets suspended in the continuous phase come together, or coalesce, as the mixture moves through the coalescer medium.

Contaminant-free liquid and large droplets of the dispersed phase flow toward the separator located directly below the coalescer stage. The flow is outside- to- inside. The separator medium is hydrophobic preventing the aqueous phase from entering the separator. Only the non-aqueous continuous phase fluid flows through the separator. The two liquids are removed by separate drain connections.

Figure 4: AquaSep EL Liquid/Liquid Separation System with an Integrated Coalescer/Separator Stack in a Vertical Housing with a Prefilter