Datasheets

Download:New Coralon Max filter elements are now available to upgrade Pall HC8304 and HC8314 Ultipor III and Coralon elements to provide extended filter service life in industrial applications. Featuring a pleat geometry to substantially increase filter surface area and lower clean pressure drop, Coralon Max elements provide users the benefit of Stress-Resistant filter medium technology and maximum filter service life.

The optimized filter element design is suited for high viscosity and conventional lubrication and hydraulic fluid applications. The filter elements directly replace Ultipor® III filter elements in existing Pall Coreless filter housings.

| Feature | Benefit |

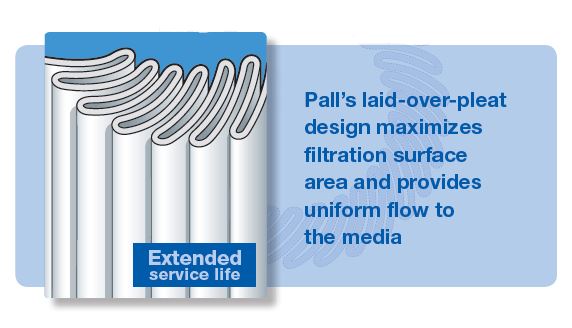

| Optimized filter medium pack design | - Low initial pressure drop - Extended filter element service life |

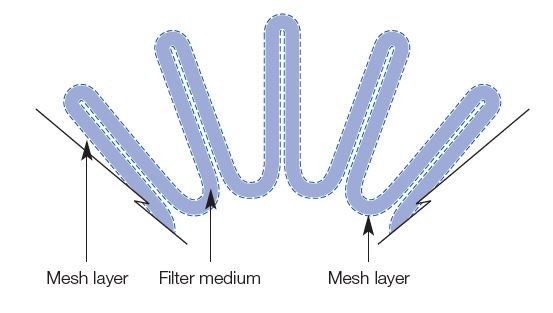

| Wave shaped pleat geometry | -Significantly increased filtration area -Uniform flow distribution through the filter element |

| High filtration efficiency rating (ßx(c) > 1000) | -Superior control of particles in critical size ranges that contribute to component wear |

| High strength construction | Consistent performance throughout filter element service life |

| Coreless, cageless, filter element configuration | -Light weight and lower disposal costs |

| Wide fluid and temperature compatibility | - Suitable for use in a wide range of applications and operating conditions |

| Same form and fit as Ultipor III filter elements | -Direct installation in existing coreless Ultipor III filter housings -High performance and value for low operating costs |

Conventional pleated filter element

Pall Coralon Long Life filter element

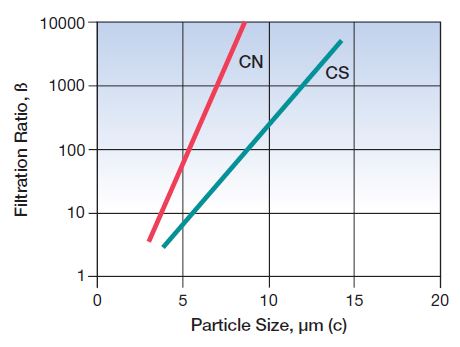

- Multi-pass filter ratings (per ISO 16889)

See figure 1 - Element Collapse Pressure Rating (ISO 2941)

10 bard (150 psid) - Fluid Compatibility (ISO 2943)

Compatible with petroleum oils, water glycols, water- oil emulsions, high water containing fluids, industrial phosphate esters and carboxylic acid esters, and most synthetic hydraulic and lubrication fluids. - Flow vs. Pressure Drop (ISO 3968)

See table 1 - Flow Fatigue (ISO 3724)

Contact factory; filter element structure incorporates upstream and downstream medium support to achieve maximum fatigue cycle life. - Fabrication Integrity (ISO 2942)

Fabrication integrity is validated and assured during the manufacturing process by numerous evaluations and inspections including Bubble Point testing. - Temperature Range

Fluorocarbon seals: -29 °C (-20 °F) to +120 °C

(+250 °F) 60 °C (140 °F) maximum for HWCF or water glycol fluids - Quality Control

All filter elements are manufactured by Pall to exacting procedures and strict quality controls. Elements are checked against rigorous ongoing validation test protocols within Pall Corporation.

Element Pressure Drop

Multiply actual flow rate times factor in table below to determine pressure drop with fluid at 32 cSt (150 SUS), 0.9 S.G. Correct for other fluids by multiplying new viscosity in cSt/32 (SUS/150) x new S.G./0.9.

Note: factors are per 1000 L/min and per 1 USgpm.

Table 1: 8334 Series Filter Elements - bard/1000 L/min (psid/USgpm)

| Length Code | CN | CS |

| 39 | 0.4245 (0.0233) | 0.4118 (0.0226) |

Figure 1: Filtration Ratios per ISO 16889

Filter Element P/N: HC8334F [Table 2] 39 Z X321

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 2: Pall Media Grade

| Code | ßx(c) ≥ 1000 Based on ISO 16889 |

| CN | 7 |

| CS | 12 |

We appreciate your review of this product. Please login to your account to leave a review.