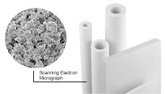

Special porous silicate granules exclusively manufactured by Pall® are sintered with a siliceous bond to form Pall Aerolith porous ceramic, a material of homogeneous composition. This porous Aerolith ceramic consists mainly of crystalline and amorphous silicates.

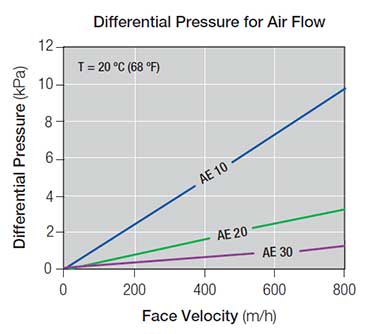

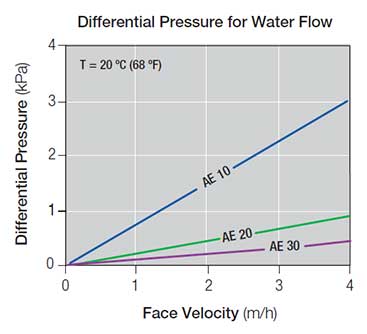

Due to high porosity and the large internal surface, the porous Aerolith ceramic products offer a high storing capacity for particles and liquids. The labyrinth structure leads to an excellent separation efficiency at a simultaneously very low increase of differential pressure.

Porous Aerolith ceramic is distinguished by the large variety of configurations, and can be used in depth filtration applications of up to 500 °C (932 °F).

General Information

- Porous Aerolith ceramic elements can be machined using hard metal tools.

- Ceramic elements are to be handled with care.

- Elements can be easily glued using commercial glues which Pall can supply. Consideration must be paid to operating temperature and chemical resistance.

- Pall can supply a variety of element fixing systems.

| Cylinders and Flanged Candles | |

| Particle filtration for Liquids | Acids, water and alcohol |

| Particle filtration for Gases | Process gases, air, sewer gas, natural gas and liquid gas |

| Coalescer | Compressed air, nitrogen and carbon dioxide |

| Storing Media | Water, colour and ink |

| Aeration Element | Drinking water, mineral water and fish ponds |

| Vacuum Lance | Retention of fire extinguishing powder |

| Plates | |

| Aeration element | Drinking water, mineral water and fish ponds |

| Nutsches | Mud thickening |

Chemical Resistance2

Porous Aerolith ceramic media is resistant to most acids, saline solutions and organic solvents, liquid or gaseous. It is resistant up to pH 9 in the alkaline range.

2As end use conditions can vary it is the users responsibility to verify compatibility with their specific use conditions.

| Aerolith (AE) | Cylinders, Flanged Candles and Plates | ||

| AE 10 | AE 20 | AE 30 | |

| Filtration Grade for Liquids | 10 μm | 25 μm | 30 μm |

| Filtration Grade for Gases | 1.5 μm | 2.5 μm | 5 μm |

| Porosity | 40 % | 40 % | 40 % |

| Material Density | 1.35 g/cm3 | 1.40 g/cm3 | 1.30 g/cm3 |

| Specific Permeability | 65 10-13 m2 | 200 10-13 m2 | 350 10-13 m2 |

| Bending Strength (O-Ring compression) | >8 MPa | >6 MPa | >4.5 MPa |

| Maximum Temperature Resistance1 | 500 °C (932 °F) | 500 °C (932 °F) | 500 °C (932 °F) |

| Expansion Co-efficient (25 - 500 °C) | 14 10-6 /K | 14 10-6 /K | 14 10-6 /K |

| Dimensions (Do / Di) | 70 / 40 mm | 70 / 40 mm | 60 / 40 mm |

1Depending on operating conditions

Flow vs Differential Pressure

| Part Number | Aerolith (AE) | Type | Do / Di (mm) | Length (mm) | Area (m2) | Weight (kg) |

| 88001200 | Cylinder | 10 | 40 / 20 | 80 | 0.010 | 0.1 |

| 88004500 | 20 | 40 / 20 | 80 | 0.010 | 0.1 | |

| 88007300 | 30 | 40 / 20 | 80 | 0.010 | 0.1 | |

| 88156500 | 10 | 60 / 40 | 1000 | 0.188 | 2.1 | |

| 88005400 | 20 | 60 / 40 | 1000 | 0.188 | 2.1 | |

| 88008100 | 30 | 60 / 40 | 1000 | 0.188 | 2.1 | |

| 88003200 | 10 | 70 / 40 | 1000 | 0.220 | 3.5 | |

| 88006100 | 20 | 70 / 40 | 1000 | 0.220 | 3.5 | |

| 88009000 | 30 | 70 / 40 | 1000 | 0.220 | 3.5 | |

| 88043000 | Flanged Candle3 | 10 | 60 / 40 | 1000 | 0.188 | 2.1 |

| 88045500 | 30 | 60 / 40 | 1000 | 0.188 | 2.1 | |

3Rectangular head 70 x 15 mm

| Part Number | Aerolith (AE) | Type | Length (mm) | Width (mm) | Height (mm) | Area (m2) | Weight (kg) |

| 88059500 | Plate | 20 | 250 | 250 | 50 | 0.063 | 4.2 |

| 88062800 | 30 | 250 | 250 | 50 | 0.063 | 4.2 | |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.