For High Throughput Depth Filtration in

Closed Systems

SUPRApak SW series depth filter modules set a new standard for enclosed sheet filtration, providing exceptional throughput and removal performance. Description

Developed from traditional depth filtration technology, SUPRApak modules efficiently combine the filtration mechanisms of surface filtration, depth filtration and adsorption. Highly unique to their design is an entirely new flow configuration, based on the “edge flow” principle.Seitz® filter sheet material is wrapped around a central, permeable core. Feed and filtrate channels provide a fluid flow path resulting in maximum utilization of the sheet material, to provide highly efficient contaminant removal and a cost-effective closed system alternative to flat sheet filtration.

| Features | Benefits |

| Flow configuration based on “edge flow” principle |

|

| Closed filtration system |

|

| Drainable, low hold-up volume assembly | Higher product yield; lower cleaning costs |

| Available in multiple grades and sizes | Suitable for a variety of applications |

| High filtration capacity in compact design | Small footprint |

| Simple, quick installation and servicing | Reduced labor and maintenance costs |

Quality

- Filter sheets produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Main Components²

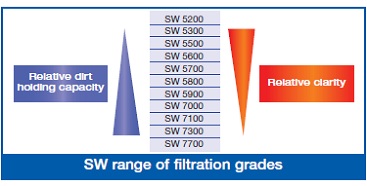

| Sheet Material SW 5200, SW 5300, SW 5500, SW 5600, SW 5700, SW 5800, SW 5900, SW 7000, SW 7100, SW 7300 | Cellulose, diatomaceous earth (DE, Kieselguhr) perlites |

| SW 7700 | Cellulose |

| Center Core | Polypropylene (20% talc-filled) |

| Straps | Polyester |

²For more information on materials of construction, please see the Declaration of Compliance at

| Final Filtration | Enzyme solutions, sweeteners |

| Polishing Filtration | Sweeteners, beer, wine, flavors, distilled spirits, thin liquor gelatin, yeast extract |

| Clarifying Filtration | Beer, wine, enzymes, distilled spirits, flavors, thin liquor gelatin, polyols, edible oils |

| Coarse Filtration | General particle removal, wax removal in edible oils |

Technical Information

Operating Characteristics in Compatible Fluids³

| Module Size | Grade | Max. Operating Temperature |

| SUPRApak S, M, L | SW 5200–SW 7300 | 75 °C (167 °F) / 8 hours4 |

| SUPRApak S, M, L | SW 7700 | ambient |

4Laboratory tests up to 8

Operating Guidelines

Field experience shows that maximum achievable differential pressures vary with the applications and product selection. They are determined by monitoring filtrate| Module | Dry Weight | Wet Weight | Ash Content5 |

| SUPRApak S (SW 5200 – SW 7300) |

1.6 –1.8 kg (3.5 – 4 lbs) |

3.5 – 4.5 kg (7.7 – 9.9 lbs) |

35 – 49% |

| SUPRApak S (SW 7700) | 1.2 kg (2.6 lbs) |

3.1– 3.8 kg (6.8 – 8.4 lbs) |

<2% |

| SUPRApak M (SW 5200 – SW 7300) |

5.1 – 5.6 kg (11.2–12.3 lbs) |

15.5 –16.5 kg (34.1–36.3 lbs) |

40 – 54% |

| SUPRApak M (SW 7700) | 3.8 kg (8.4 lbs) |

13 –15 kg (28.6 – 33 lbs) |

<2% |

| SUPRApak L (SW 5200 – SW 7300) |

11–12 kg (24.2–26.4 lbs) |

25 – 30 kg (55 – 66 lbs) |

40 – 54% |

| SUPRApak L (SW 7700) | 7.5 kg (16.5 lbs) |

25–30 kg (55–66 lbs) |

<2% |

Sanitization6

| Method | Temperature | Max. Differential Pressure (forward) |

Time/Cycles7 |

| Hot Water | 85 °C (185 °F) | 1.5 bard (21.7 psid) | 10 cycles @ 20 min each |

7The actual time required may vary as a function of the process conditions. Laboratory tests were carried out up to 10 cycles. Actual field experience shows more cycles are achievable, coupled with proper filtrate quality monitoring.

Rinsing8

| Module Size | Rising Volume/Module | Recommended Flow Rate | |

| SUPRApak S | 20 liters (5.3 |

1.5 times filtration flow rate | |

| SUPRApak M | 140 liters (37 |

1.5 times filtration flow rate | |

| SUPRApak L | 340 liters (90 |

1.5 times filtration flow rate | |

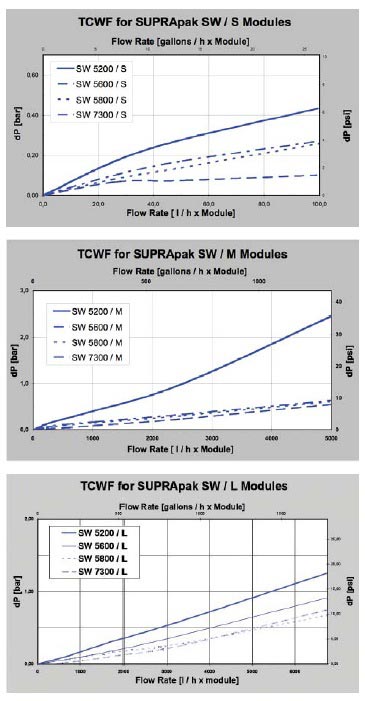

Typical Flow Rates9

TCWF for SW 7700 Modules

Due to the high permeability of SUPRApak SW7700 modules, initial clean water differential pressures at the typical flux rates used for these modules are negligibly low and influenced by measurement accuracy.| Module | Flow Rate/Module | Initial Differential Pressure9 |

| SUPRApak M, L (SW 7700) | ≤ 5000 liters/hour (22 gal/min) | ≤ 400 mbar (5.8 psid) |

9TCWF: Total Clean Water Flow. Typical initial clean delta p per module, water at 20° C (68° F), viscosity 1 cP. For assistance with filter sizing, please contact Pall.

Filter Sheets

This is a guide to the part numbering structure and possible options only. For availability of specific options, please contact Pall.

Example Part Number: SUPRApak SW 5200 L W (See bold references in tables below.)

Part Number: SUPRApak SW < Grade code from Table 1>< Nominal Dimension Code from Table 2> W

Table 1 - Grade

| Code |

| 5200 |

| 5300 |

| 5500 |

| 5600 |

| 5700 |

| 5800 |

| 5900 |

| 7000 |

| 7100 |

| 7700 |

| 7300 |

Table 2 - Nominal Dimensions

| Code | Height | External Diameter |

| S | 250 mm (9.8 in.) | 183 mm (7.2 in.) |

| M | 250 mm (9.8 in.) | 285 mm (11.2 in.) |

| L | 250 mm (9.8 in.) | 415 mm (16.3 in.) |

Each SUPRApak M and L module is supplied with a separate polypropylene ring for use in between adjacent modules.

Many applications in the food and beverage industry are ideally suited to the use of SUPRApak technology, resulting in significant commercial and technical advantages.

At one installation at a brewery, the use of SUPRApak technology saves 68% on operating costs, compared to classical sheet filtration.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.