Efficient, Economical and Innovative

The Future of Depth Filtration with Filter Sheets

SUPRApak depth filtration enters a completely new generation with a unique flow configuration called “edge flow”. This cost-effective technology will revolutionize depth filtration in the food and beverage sector. For over 100 years, filter sheets have been used in the food and beverage industry to filter liquids in classic plate and frame filters. The unique filter matrix comprised of cellulose, diatomite and perlite combined with the surface, depth, and adsorptive filtration capabilities of filter sheets makes them an attractive option for a very wide range of applications. Increased demand for environmentally compatible production processes and product quality in the food and beverage industry has intensified the need to seek out alternative filtration systems. At the same time, cost pressures demand that filter systems are simple to operate with low staffing costs. Classic sheet filters have considerable disadvantages, such as the high cost of filter change-outs and cleaning, an open system combined with drip losses, the risk of microbiological contamination and the space required for the filter assembly. However, it is not always possible to replace filter sheets with different filtration systems economically and efficiently due to stringent, and at times, complex filtration requirements. In response to industry demands to replace classic sheet filters, Pall has introduced the new SUPRApak filter module. Based on proven Seitz sheet technology, SUPRApak modules are revolutionizing the market for depth filters with sheet filtration.- Particle filtration

- Colloidal removal

- Polishing filtration

- Final filtration

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- SUPRApak Depth Filter Modules (SH Range) Declaration of Compliance

- SUPRApak Depth Filter Modules (SR Range) Declaration of Compliance

- SUPRApak Depth Filter Modules (SW Range) Declaration of Compliance

SUPRApak Module Design

The SUPRApak filter design is an entirely new and unique configuration of filter sheet material, which sets a new standard for enclosed sheet filtration.SUPRApak modules are based on classic depth filtration technology, and represent a perfect combination of the three filtration mechanisms: surface filtration, depth filtration and adsorption.

The main components are high purity cellulose, diatomite and perlite. Unique to the SUPRApak module is an entirely new depth filter flow configuration based on the “edge flow” principle. The filter sheet material contains feed and filtrate channels wrapped around a permeable core.

The main components are high purity cellulose, diatomite and perlite. Unique to the SUPRApak module is an entirely new depth filter flow configuration based on the “edge flow” principle. The filter sheet material contains feed and filtrate channels wrapped around a permeable core. Straps are used to attach the sheet material to the core.

Straps are used to attach the sheet material to the core.

This design results in a compact dense package of high-quality filter sheet material. Thus the SUPRApak module meets the highest demands in terms of purity and clarity of the filtered product.

SUPRApak Filter Media

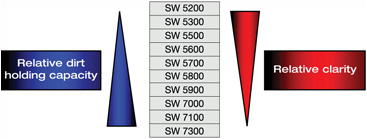

SUPRApak SW Range (Standard)

Filter material in the SW range is made from high-grade cellulose, diatomite and perlite as well as <3 % polyolefin fibers. The SUPRApak SW range offers 10 filtration grades ranging from type SW 5200 for final filtration to type SW 7300 for removing coarse particles.

| SW Range | Examples of use |

| SW 5200 | Final filtration of enzyme solutions Final filtration of sugar solutions |

| SW 5300 | Final filtration of fructooligosaccharides Fine filtration of beer |

| SW 5500 | Final filtration of sugar solutions Fine filtration of beer |

| SW 5600 | Final filtration of sugar solutions Fine filtration of beer |

| SW 5700 | Clarifying filtration of beer Final filtration of sugar solutions |

| SW 5800 | Filtration of enzyme solutions Clarifying filtration of beer |

| SW 5900 | Polishing filtration of thin liquor gelatine Polishing filtration of flavors Clarifying filtration of beer |

| SW 7000 | Clarifying filtration of thin liquor gelatine |

| SW 7100 | Clarifying filtration of thin liquor gelatine Clarifying filtration of flavors |

| SW 7300 | Coarse particle removal |

SUPRApak SR Range (High Resistance)

The filter material in the SR range contains up to 40 % selected polyolefin fibers in addition to cellulose, diatomite and perlite. This composition of raw materials is specially designed to meet the demands for filtration of aggressive media, as it has high chemical and mechanical resistance compared with the SUPRApak SW range. As a result of the polyolefin fibers, the SUPRApak SR modules are highly resistant to enzymes which break down cellulose, making them the ideal choice for use in the enzyme industry.

| SR Range | Examples of use |

| SR 5100 | Final filtration of enzyme solutions |

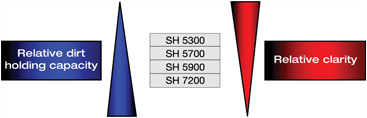

SUPRApak SH Range (Ion Reduced)

For special applications like distilled spirits filtration, the SUPRApak SH range of modules is the preferred option. With a proprietary manufacturing process, these sheets release low levels of calcium and magnesium, and negligible levels of iron and copper.

| SH Range | Examples of use |

| SH 5300 | Polishing filtration of white spirits |

| SH 5700 | Polishing filtration of white spirits |

| SH 5900 | Chill haze removal in whiskey |

| SH 7200 | Chill haze removal in brandy |

User advantages

- Increased process safety and product quality due to enclosed, hygienic system

- Increased process uptimes, as the edge flow principle can allow longer throughputs and use of the full capacity of the depth filter material

- High turbidity reduction due to increased particle adsorption capacity

- High yields due to low hold-up volume, drainability of the assembly, and elimination of product drip losses

- Cost savings on filter change-outs due to modular construction, no time-consuming insertion and stacking of individual filter sheets, and less handling in between production runs

- Reduced cleaning chemical and water costs due to compact design

- Small footprint due to high packing density and resulting large filtration area per unit

- Easy disposal of modules

- Low capital investment compared to classical plate and frame assemblies

- Secure operation without bypass due to external tensioning control

- Low maintenance costs due to absence of gaskets on modules and very limited number of housing seals

- Low total cost of ownership due to combined savings on unit filter area, yield, handling, cleaning, and maintenance, and increased production availability

Filter Sheets

Select the language below:

| SUPRApak™ modules for beverage filtration - English |

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Example Part Number: SUPRAPAK SW 5200 LW (See bold references in tables below)

Part Number: SUPRAPAK < Module Code from Table 1 > < Media Code from Table 2 > < Dimensions Code from Table 3 > W

Table 1 - Module Type

| Code | Range |

| SW | Standard |

| SR | High Resistance |

| SH | Ion Reduced |

Table 2 - Media Range

| Code | Range |

| 5200 | SW Range |

| 5300 | |

| 5500 | |

| 5600 | |

| 5700 | |

| 5800 | |

| 5900 | |

| 7000 | |

| 7100 | |

| 7300 | |

| 5100 | SR Range |

| 5300 | SH Range |

| 5700 | |

| 5900 | |

| 7200 | |

Table 3 - Nominal Dimensions

| Code | Height | External Diameter |

| XS | 70 mm (2.8 ") | 183 mm (7.2 ") |

| L | 250 mm (9.8 ") | 415 mm (16.3 ") |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.