The IonKleen SL purifier has been specifically designed for the removal of metal ions from organic solvents and mixtures of organic solvents and resins. It is well-suited for use with raw materials used in the production of photoresists and for ultra high purity solvent applications. By utilizing ion exchange groups, which are covalently bonded directly to the surface of a traditional membrane filter, the IonKleen SL purifier provides spontaneous and immediate metal removal from various base solvents and resin solvent mixtures.

Features

- 90% metal removal

- Simplifies purification techniques

- High capacity

- Shipped dry

- Manufactured in a cleanroom environment

Recommended Applications

The IonKleen SL purifier is recommended for solvent point-of-use purification and for use in purifying the precursor materials (solvents, resins and polymers) used in the manufacture of photoresists. It has also shown positive results in the purification of bulk and point-of-use IPA dispense.

Material of Construction

| Components | Materials | ||

| Configurations | ABD1 | DFA1 | PHD22 |

| Medium | Modified ultra-high molecular weight polyethylene (UHMWPE) | ||

| Support and Drainage | High density polyethylene (HDPE) | ||

| Core and Cage | High density polyethylene (HDPE) | Polypropylene | High density polyethylene (HDPE) |

| End Caps | High density polyethylene (HDPE) | Polypropylene | High density polyethylene (HDPE) |

| Shell | - | Polypropylene | High density polyethylene (HDPE) |

| Media Area | 0.58 m2 / 6.24 ft2 | 0.11 m2 | 0.11 m2 |

| Total Metal Ion Exchange Capacity (90% Efficiency) |

> 80 meq | > 16 meq | > 16 meq |

| Maximum Operating Temperature | 30 °C/ 86 °F | ||

| Maximum Forward Differential Pressure | 0.34 MPa/ 50 psid | ||

| Maximum Operating Pressure | - | 0.49 MPaG (30 °C) / 71 psig (80 °F) | 0.39 MPa (23 °C) / 57 psig (73 °F) |

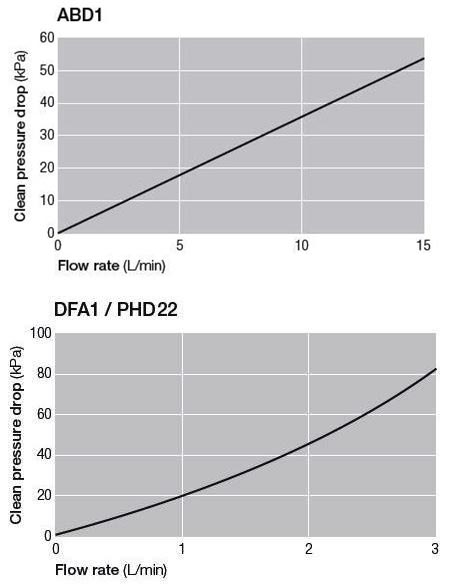

Pressure Drop vs. Liquid Flow Rate (Water, 20 °C)

Recommended Flow Rate

| Filter Configurations | Recommended Flow Rate in ethyl lactate1 |

| ABD1 | 1.9 L / min |

| DFA1 /PHD22 | 0.36 L / min |

1The clean pressure drop is 1.96kPa.

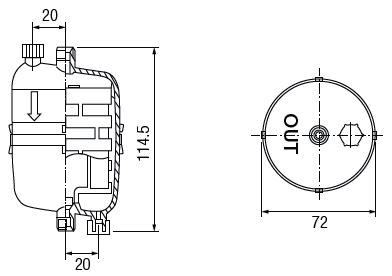

Filter Capsule Dimensions

Part Numbers / Ordering Information

ABD1 Cartridge

ABD [1] SRP [2] E [3]

Table 1 |

||

| Code | Nominal length (mm / in) | |

| 1 | 254 / 10 | |

| 2 | 508 / 20 | |

| 3 | 762 / 30 | |

Table 2 |

||

| Code | O-ring Specifications | |

| 3 | AS568A-222 | |

Table 3 |

||

| Code | O-ring Materials | |

| H1 | FEP Encapsulated Fluoroelastomer | |

DFA1 Capsule DFA1SRPESW44 |

||

| Code | Connections | |

| Inlet / Outlet | Vent / Drain | |

| SW44 | 1⁄4 in Swagelok2 | 1⁄4 in Swagelok2 |

2Swagelok is a trademark of Swagelok Co.. |

||

PHD22 Capsule PHD22SRPEH11 |

||

| Code | O-ring Materials | |

| H11 | Perfluoroelastomer | |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.