- Deep, wide pleats for long service life in liquids with high levels of suspended solids

- High filter area, combined with continuously profiled pore structure minimizes sheer

- Steep efficiency curves result in minimal strip-out of desirable slurry particles while sharply increasing removal of oversized particles

Specifications

Materials of Construction

| Components | Materials |

| Filter Medium | Polypropylene |

| Support and drainage | Polypropylene |

| Core,cage and end caps | Polypropylene |

| Housing (DFA) | Polypropylene |

| Gasket options | EPDM, Polypropylene |

| O-ring options | EPDM, Silicone, Fluoroelastomer |

| Product Name | 10 inch cartridges | DFA capsules |

| Removal Ratings (μm) | 0.8, 1, 1.5, 3, 5, 10, 15 | 0.8, 1, 1.5, 3, 5 |

| Maximum Operating Temperature | 80 °C / 176 °F | 38 °C / 100 °F |

| Maximum forward differential pressure | 0.50 MPa / 70 psid @ 50 °C / 120 °F 0.34 MPa / 50 psid @ 80 °C / 176 °F | 0.34 MPa / 50 psid @ 80 °C / 176 °F |

| Maximum Operating Pressure | - | 0.49 MPaG / 71 psig @ 38 °C / 100 °F |

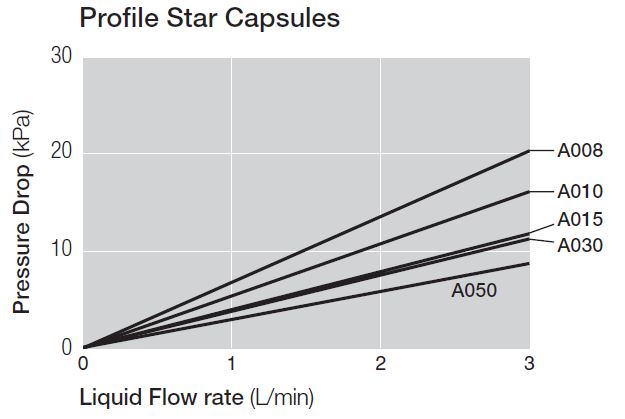

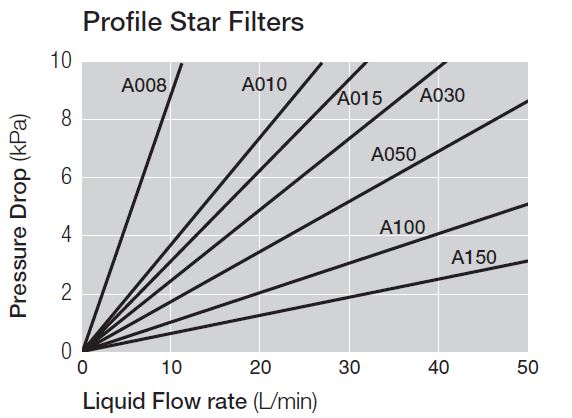

Pressure Drop vs. Liquid Flow Rate1 (Water 20 ºC )

1 Typical flow rates. For liquids with a viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Unit conversion: 1 bar = 0.1 MPa

Part Numbers Ordering Information

Gasket Seal Filters

PUY [1] A [2] [3]

Table 1

| Code | Cartridge Length (Nominal) |

| 1 | 254 mm / 10 in |

| 2 | 508 mm / 20 in |

| 3 | 762 mm / 30 in |

Table 2

| Code | Removal Ratings2 (μm) |

| 008 | 0.83 |

| 010 | 14 |

| 015 | 1.5 |

| 030 | 3 |

| 050 | 5 |

| 100 | 10 |

| 150 | 15 |

Table 3

| Code | Gasket Materials |

| J | EPDM (Standard) |

| Y1 | Polypropylene |

O-ring Seal Filters

AB [1] A [2] [4] [5]

Table 4

| Code | O-ring Specifications |

| 3 | AS568A-222 |

| 7 | AS568A-226 |

| 255 | AS568A-222 |

Table 5

| Code | Gasket Materials |

| J | EPDM (Standard) |

| H4 | Silicone |

| H | Fluoroelastomer |

2 Removal ratings at 99.98% efficiency based on a modified OSU-F2 single pass test in aqueous medium.

3 Removal ratings at 94% efficiency.

4 Removal ratings at 99.8% efficiency.

5 Options for 0.8 μm only.

DFA Capsules

DFA [6] A [7]

Table 6

| Code | Connections | Vent / Drain | ||

| Tube size | Configurations | Tube size | Configurations | |

| 4201 | 1/4" in | NPT male | 1/8" in | NPT male |

| 5301 | 16 mm | 1/4" Swagelok6 | 4 mm | Swagelok |

Table 5

| Code | Removal Ratings1 (μm) |

| 008 | 0.83 |

| 010 | 1 |

| 015 | 1.5 |

| 030 | 3 |

| 050 | 5 |

6 Swagelok is a trademark of Swagelok Co.

Representative example part numbers

AB1A00825J | AB1A0503J |

AB2A00825J | AB2A0503J |

AB1A0103J | AB1A1003J |

AB2A0103J | AB2A1003J |

AB1A0153J | AB1A2003J |

AB2A0153J | AB2A2003J |

AB1A0303J | |

AB2A0303J |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.