High Consistency Polypropylene

Melt Blown Cartridge

- Graded pore structure enhances dirt-holding capacity

- E-core, an Extruded Fibrous Core, provides excellent strength

- Unique proprietary process

- Easy and safe cartridge incineration and disposal

- All polypropylene construction

- No surfactants, binders, or adhesives

- NSF certified

- Plastic and metal spring assembly end configurations are available

Performance Specifications

Filter grades

- 1, 3, 5, 10, 20, 30, 50, 75 micron (μm)

Maximum differential pressure

- 3.45 bard (50 psid) @ 20 °C (68 °F)

- 1.72 bard (25 psid) @ 60 °C (140 °F)

Recommended change-out differential pressure1

- 2.4 bard (35 psid)

Food and Water Contact Use

- Please contact Pall Corporation to verify that the product conforms to your national legislation and/or regional regulatory requirements for water and food contact use.

Purity

- Cartridges do not use surfactants, anti-static agents, binders, and adhesives.

Product Specifications

Materials of construction

| Filter media: | Polypropylene |

| End caps2: | Polypropylene |

| Extended core2: | Stainless steel |

| Extruded core: | Polypropylene |

| Gaskets/O-rings2: | Silicone elastomer, nitrile, fluorocarbon elastomer, EPDM, Santoprene3 |

Dimensions (nominal)

| Outside diameter: | 6.4 cm (2.5 in.) |

| Inside diameter: | 2.7 cm (1.07 in.) |

| Lengths: | 24.8 cm (9.75 in.), 25.1 cm (9.875 in.), 25.4 cm (10 in.), 49.5 cm (19.5 in.), 50.2 cm (19.75 in.), 50.8 cm (20 in.), 74.3 cm (29.25 in.), 74.9 cm (29.5 in.), 75.6 cm (29.75 in.), 76.2 cm (30 in.), 99.1 cm (39 in.), 102 cm (40 in.), 127 cm (50 in.) |

1 Provided that the maximum differential pressure is not exceeded based on temperature limits defined above.

2 These components are not NSF certified.

3 Trademark of Exxon Mobil Corporation.

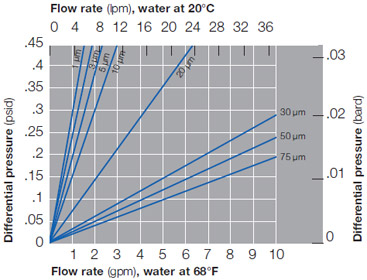

Typical Flow vs. Differential Pressure for Application Sizing

Unit conversion: 1 bar = 100 kPa

Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Filter Cartridges

Pall Part Number = CLR - [1] - [2] [3] [4]

4 Based on typical application usage.

Table 1

| Code | Filter grades (μm)4 |

| 1 | 1 |

| 3 | 3 |

| 5 | 5 |

| 10 | 10 |

| 20 | 20 |

| 30 | 30 |

| 50 | 50 |

| 75 | 75 |

Table 2

| Code | Cartridge lengths (cm/in.) nominal |

| 9.75 | 24.8/9.75 |

| 9.875 | 25.1/9.875 |

| 10 | 25.4/10 |

| 19.5 | 49.5/19.5 |

| 19.75 | 50.2/19.75 |

| 20 | 50.8/20 |

| 29.25 | 74.3/29.25 |

| 29.5 | 74.9/29.5 |

| 29.75 | 75.6/29.75 |

| 30 | 76.2/30 |

| 39 | 99.1/39 |

| 40 | 102/40 |

| 50 | 127/50 |

Table 3

| Code | End configurations |

| Blank | DOE industrial (no end caps) |

| DOE | DOE with elastomer gasket seals & end caps |

| H21 | DOE, Santoprene gasket seal |

| 1X | DOE industrial, 2.54 cm (1 in) stainless steel extended core |

| M3 | SOE flat closed end, external 222 O-rings (retrofits other manufacturers' Code 0)5 |

| M6 | SOE flat closed end, external 226 O-rings (retrofits other manufacturers' Code 6)5 |

| M7 | SOE fin end, external 226 O-rings (retrofits other manufacturers' Code 7)5 |

| M8 | SOE fin end, external 222 O-rings (retrofits other manufacturers' Code 5)5 |

| M18 | SOE flat closed end, external 222 O-ring |

| XK | SOE plastic spring assembly, saw cut end |

| SI | SOE metal spring/polypropylene cap, saw cut end |

Table 4

| Code | Gasket/O-ring materials |

| S | Silicone |

| N | Nitrile |

| E | EPDM |

| V | Fluorocarbon elastomer |

4 Based on typical application usage.

5 For details, contact Pall Corporation.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.