Please Note: The following information is provided to support existing users of Pall Cleanliness Cabinets (PCCs) for technical reference and order of consumables and spare parts. The complete cabinet assemblies are no longer available to purchase.

The Pall PCC61-KC Cleanliness Cabinet facilitates the accurate, reliable and repeatable preparation of gravimetric membranes for the determination of component cleanliness.

The PCC61-KC cabinet enables operators to access the cleanliness level of manufactured parts and components in accordance with ISO18413, ISO16232 and VDA 19 procedures. Features

- Large work area for large manufactured parts

- Reliable and repeatable measurements

- HEPA filtered laminar air flow in a self contained super polished stainless steel working area

- Simple to install and operate

- Fully portable requiring only a power source

- Designed and built to ISO Pressure Washing standard 16232

- Solvent dispensing gun with fluid volume dispensing counter

- Pressurized solvent dispensing and recycling circuits

- Gravimetric membrane holder

- Auto Wall Wash function

- PLC controlled operating parameters (option)

General Specifications

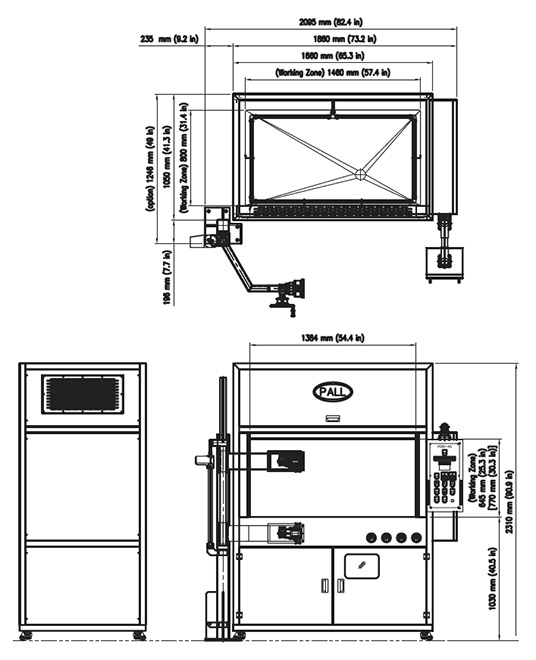

- Dimensions: 1660mm (W) x 1050mm (D) x 2310 (2330mm with a projected blower port) (H)

- Inputs:

- 220 or 380 or 415 V AC

- 50 or 60Hz, 1 or 3 phase

- Working area: 1460mm (W) x 800mm (D) X 770mm (660mm at the entrance) (H)

- Fluorocarbon seals, BA grade SUS304 materials are standard

- Air flow ISO14644-123 Class 5

- Polished stainless steel extraction enclosure

- Controlled cleanliness environment (Class 5 per ISO 14644-1)

- HEPA filter rating: 0.3m absolute

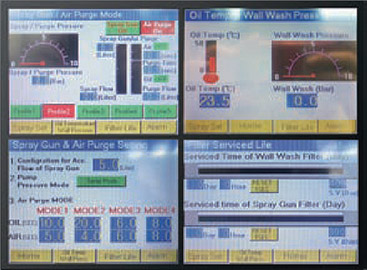

- Control panel with colored touch screen

- Maximum flash point of wash fluid > 55 °C

- Test membrane holder in the power zone

- Noise level in working conditions: < 80dB

Cabinet Option

Touch Screen PLC 5” (Optional Human Machine Interface)

Technical Specification Information

- Power Inputs: 220V 50 or 60Hz, 1 or 3 Phase

- Electric Power Consumption: 1.5KW (~6A)

- Reservoir (solvent): 50L (with fluid level Indicator)

- Spray Rinsing flow rate: Set 2.5L/min adjustable,

- Total Spray Volume: pre-configurable (1L, 2L,etc)

- Wall Wash flow rate: ~12L/min (adjustable)

- Spray Rinse pressure: Set 5bar (adjustable, max.7bar)

- Wall Wash Solvent filter rating 0.2 m +1 m; (2 stages Absolute)

- Dry weight: 800kg

- Inlet Fan Blower Flow Rate: ~1500mm3/Hr

- Air flow Speed Controllable by Dimmer Switch

- Outlet Fan Blow Flow Rate: ~2200mm3/Hr

- Air flow Speed Controllable by Dimmer Switch

- Membrane Holder:

- 2 Stages Cascade, 47mm Dia.

- 3 Stages Cascade (option)

- Chemical Compatibility: synthetic hydrocarbon fluids

- Vacuum pump: -0.65~-0.85bar vacuum pressure

Diagnostic and Monitoring Equipment

Filtration, Polishing, Prefiltration, Removal

PCC61-KC [Table 1] [Table 2] [Table 3] [Table 4]

Table 1: Option

| Code | Description |

| Omit | Standard |

| T5 | Touch Screen PLC-5” size |

| T7 | Touch Screen PLC-7” size |

| T8 | Touch Screen PLC, 8”size display |

Table 2: Option

| Code | Description |

| S | Shower Nozzle Line |

| P | Oil & Air purge and Nozzle Line Addition |

Table 3: Option

| Code | Description |

| R | 220V AC 60Hz 1Phase |

| W | 220V AC 50Hz 1Phase |

| X | 220V AC 50Hz 3Phase |

| Y | 380V AC 50Hz 3Phase |

| Z | 415V AC 50Hz 3Phase |

| V | 200V AC 50Hz 3Phase |

Table 4: Option

| Code | Description |

| Omit | PCC alone without Lift Arm |

| 65LT | Auto Lift Arm 65kgf |

| 100LT | Auto Lift Arm 100kgf |

| 150LT | Auto Lift Arm 150kgf |

Auto Original Paint, Auto Paint Process Water, Auto Painting/Coating Sludge Separation, Auto Painting/Coating Zinc Phosphate Bath, Auto Power Train Dept: Parts Washing, Test Stands (Metal Chip Filtration), Auto Painting/Coating Zinc Phosphate Bath

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.