filtration of process fluids and effluents

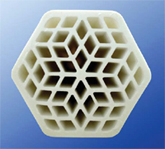

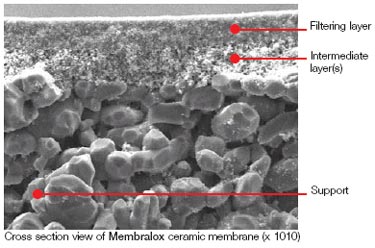

Pall Membralox IC ceramic elements are asymmetic

multi-channel membranes composed of a porous

alumina support and a filtering layer (alumina, zirconia, titania).

The revolutionary patented design provides a higher

surface area per membrane than an equivalent channel

diameter.

Key Features

- High module flow rate

- Wide chemical and pH (0-14) compatibility

- Excellent thermal stability

- Long term and reliable performance

- Sanitable and sterilizable

- Ability to withstand high frequency backpulsing cycles

- 100% bubble point integrity tested during manufacturing

- Suited for high fouling fluids, viscous products,

high concentration factors, fine filtration, diafiltration,

automatic and easy cleaning in place (CIP). - Meets the requirements for food usage**.

Pall Membralox Membranes Quality

- Unique ceramic support of the 12 µm pore size

allows the highest flux. - Patented alumina end-sealing provides superior

resistance to corrosion and cleaning cycles. - High homogeneity and quality of the filtration layers

for optimum filtration performances and selectivity. - Exceptional mechanical resistance for long service life.

Cost Effective Separations

The superior characteristics of Pall Membralox IC ceramic

membranes provide a highly cost effective solution on the

market:

- Less filtration modules and small system footprint

- Lower investment cost

- Shorter return on investment

* 4mm Channel diameter

** The membranes based on high purity alumia are certified for use in contact with food fluids by Commission Directive 2005/31/EC All membrane components are made from materials that our suppliers state meet the requirements for food contact use: Alumina and titania are GRAS, Zirconia layers on alumina suport are listed in 21 CFR Sect. 177.2910.

- Fermentation broth clarification, molecules extraction, purification and concentration.

- Clarification of glucose syrups and fruit juice, beer recovery.

- Degreasing bath regeneration, oily waste water treatment, hydrocarbons/water separation, solvent recovery.

- Waste water treatment with ceramic membrane bioreactor (MBR)

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.