CMP StarKleen™ Nano filter capsules have been developed for the classification of both ceria and low solids colloidal silica slurries at or near tools used in advanced CMP processes, such as shallow trench isolation (STI) and barrier copper. Pall’s most advanced melt-blowing process has been utilized to manufacture extremely fine fibers that improve removal efficiency of particles as fine as 100 nm. The ultra-fine fiber matrix is ideally suited for removing particles like ceria that are predominantly captured by mechanical filtration mechanisms like sieving.

- Multi-zone pore construction optimizes both efficiency and long service life

- Compact, completely disposable all-polypropylene material with Flare style connections for easy change-outs. Vents and drains are available with either NPT or Flare style fittings

- Each zone is manufactured to a given specification that ensures consistent, reproducible performance

- Steep efficiency curves result in minimal strip-out of desirable slurry particles while sharply increasing removal of oversized particles

| Materials |

|

| Removal ratings |

|

| Operating conditions1 |

|

| Connections |

|

1In compatible fluids which do not soften, swell, or adversely affect the filter performance or materials of construction.

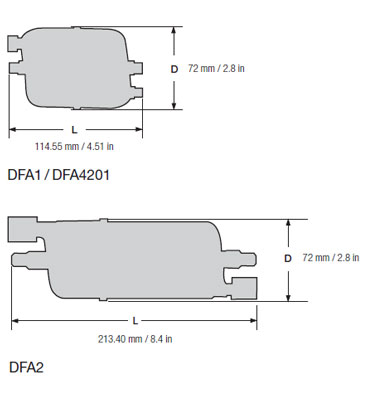

Dimensions

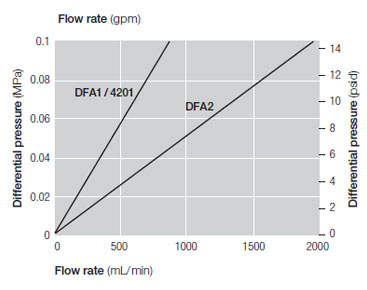

Pressure Drop vs. Liquid Flow Rate3

3For liquids with a different viscosity than water, multiply the pressure drop by the viscosity in centipoise.

Part Numbers / Ordering Information

| Part number | Removal Rating | Connections Inlet, outlet / Vent, drain |

Nominal length (mm/in) |

| DFA4201NP100 | 100 nm | 1/4” NPT / 1/8” NPT | 114.55 / 4.51 |

| DFA1NP100FL4N2 | 100 nm | 1/4” Flare style / 1/8” NPT | 114.55 / 4.51 |

| DFA2NP100F64 | 100 nm | 3/8” Flare style / 1/4” Flare style | 213.40 / 8.4 |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.