Order Products

50/EA

50

Reduce your risk of precipitation in distilled spirits

Seitz Ion Reduced (IR) Depth Filter Sheets are part of the IR series of products. These media undergo a proprietary treatment that results in extremely low extractable ions, making them the ideal solution for distilled spirit applications. The homogenous and consistent media include surface, depth and adsorptive filtration for high solids retention, which gives you high solids retention, very good permeability and excellent filtrate quality. Available in multiple grades.

Polishing filtration in white spirits

Chill filtration of white spirits

Chill filtration of tannin-containing spirits or white spirits high in fatty acids

Particle removal

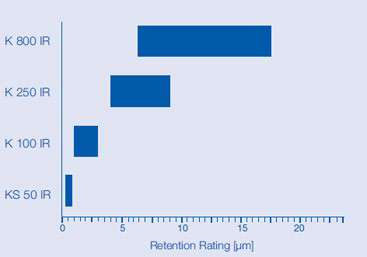

Relative Retention Rating1

Food Contact Compliance

Main Constituents

Cellulose, diatomaceous earth (DE, Kieselguhr), perlite

Characterization

| Grade | Mass per Unit Area g/m2 |

Thickness mm |

Ash % |

Water Permeability2 L/m2/min (gal/ft2/min) |

|---|---|---|---|---|

| KS 50 IR | 1350 | 3.7 | 46 | 93 (2.3) |

| K 100 IR | 1400 | 4.3 | 51 | 187 (4.6) |

| K 250 IR | 1250 | 4 | 46 | 510 (12.5) |

| K 800 IR | 1250 | 4.1 | 46 | 1275 (31.4) |

These figures have been determined in accordance with in-house test methods and the methods of the Technical / Analytical Work Group within the European Depth Filtration Association.

2The permeability was measured under test conditions with clean water at 20° C (68° F) and a Δp of 1 bar (14.5 psi).

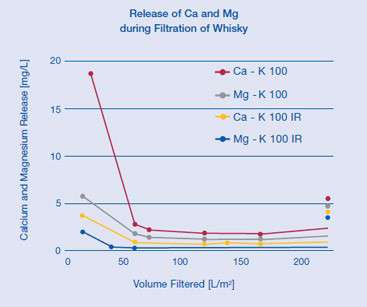

The diagram below illustrates the release of calcium and magnesium from the comparable standard filter sheet K100 and K100 IR into whisky during filtration.

The following total calcium and magnesium release per m2 filter sheet at a flow velocity of 500 L/m2/h (12.3 gal/ft2/h) was calculated during this filtration run:

| Sheet | Calcium mg/m2 (%) | Magnesium mg/m2(%) |

|---|---|---|

| K 1003 | 667 (100) | 192 (100 |

| K 100 IR | 146 (22) | 68 (35) |

3The K 100 is the comparable standard sheet to the K 100 IR with regard to the material composition.

Quality

The use of ion-reduced water (deionized water) is highly recommended for the reconstitution of distillates to single strength.

To prevent dilution upon installation, a water rinse is not recommended for sheet filters used in the spirits industry. Product circulation for 10 to 15 minutes back to the feed tank helps distribute ions extracted at the beginning of filtration to the entire batch, reducing precipitation's overall risk.

Filtration Guidelines4

As the filtrate quality can be impacted by the filtration flow rate, the following table provides flux rate guidelines.

| Application | Flow Velocity L/m2/h (gph/ft2) |

|---|---|

| Particle filtration of brown spirits | 500 – 700 (12.3 – 17.2) |

| Particle filtration white spirits | 700 – 900 (17.2 – 22.1) |

| Chill filtration of brown spirits and white spirits high in fatty acids | 250 – 400 (6.1 – 9.8) |

| Chill filtration of white spirits | 400 – 600 (9.8 – 14.7) |

4 Please contact Pall for recommendations on your specific filtration process as results may vary by product, pre-filtration and filtration conditions.

For additional operating guidelines, please refer to the instructions provided by Pall.