Datasheets

Download:The Ultramet-L® 6600 Series Filter Assembly is an all 316L stainless steel filter designed for ≥ 1.5 nanometer (0.001.5 μm) filtration of semiconductor process gases.

- All 316L stainless steel construction

- State-of-the-art 316L stainless steel media

- Preconditioned to ultraclean levels

- Accommodates extremely high flow rates for assembly size

- Excellent gas displacement and desorption characteristics

- High temperature and pressure capabilities

- 100% helium leak tested

- Cleanroom manufactured and packaged

- CE marked in accordance with PED 97/23/EC

| Filter Medium | 316L stainless steel1 |

| Internal Surface Finish | 6601: ≤ 10 μin / 0.25 μm Ra 6602: ≤ 0.7 μm Rmax |

| Housing | Electropolished 316L stainless steel Housing material meets or exceeds VIM / VAR specifications |

| Removal Rating | ≥ 1.5 nm |

| Preconditioned Cleanliness | <10 ppb moisture contribution (Qualified per SEMASPEC test method #90120397B-STD) |

| <10 ppb THC contribution (Qualified per SEMASPEC test method #90120396B-STD) | |

| <10 ppb O2 contribution (Qualified per SEMASPEC test method #90120398B-STD) | |

| <1 particle/(ft3 or m3) particle contribution above background | |

| Connections | 1⁄2" Gasket Seal, Male / Male (VCR2 or compatible) |

| Leak Rating | 100% helium leak tested to 10-9 atm•cm3/s |

| Design validated to 10-11 atm•cm3/s | |

| Maximum Operating Pressure | 750 psig @ 100 °F/52 bar @ 38 °C 550 psig @ 800 °F/38 bar @ 426 °C for inert gases only |

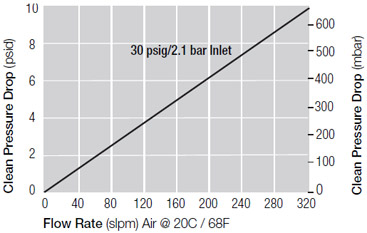

| Maximum Forward Differential Pressure | 30 psid @ 68 °F/2.1bar @ 20 °C 15 psid @ 800 °F/1 bar @ 426 °C inert gases only |

| Particle Removal Characteristics | 109 particle reduction up to 320 slpm/ 11.3 scfm |

| EU pressure equipment directive | Assemblies have been evaluated and are CE marked per the European Union’s Pressure Equipment Directive 2014/68/EU |

1 The 6600 Series Filter Assembly is also available with a nickel filter. Contact Pall Microelectronics for more information.

2 VCR is a registered trademark of Swagelok Co.

Pressure Drop vs. Gas Flow Rate

76 mm Ultramet-L Assemblies

Assemblies

Filtration

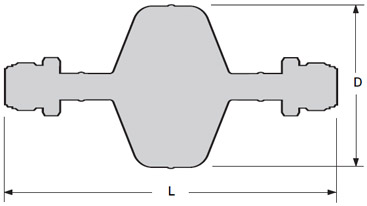

Dimensions

| Part Number | Description | ||

| GLFF6601VMM8 | 1⁄2 in. Gasket Seal (VCR or Compatible) Male/Male, ≤ 10 μin / 0.25mm Ra |

6.06 / 154 | 3.02 / 76.7 |

| GLFF6602VMM8 | 1⁄2 in. Gasket Seal (VCR or Compatible) Male/Male, ≤ 0.7 μm Rmax | 6.06 / 154 | 3.02 / 76.7 |

Unit conversion: 1 bar = 100 kilopascals

We appreciate your review of this product. Please login to your account to leave a review.