Order Products

Filter Grade

5 µm

1/EA

1

Pall’s Profile® Coreless Filter Elements combine Pall’s proven Profile depth filter technology and a design that eliminates the core. The large-diameter cartridges offer cost-efficient, consistent, and highly efficient clarification and filtration in high flow rate applications. The Profile Coreless Filter vessels are correspondingly smaller, leading to reduced installation and capital costs and lower operating costs.

The Profile Coreless filter elements facilitate easy change-outs and fit over a 316L stainless steel core that is retained inside the filter housing. Simply pulling up the element over the core makes it ready to accept the replacement element.

The filters are available in three variants to suit various applications, including –

Filter Grade

5 µm

Features and Benefits:

The Profile Coreless Filter Elements are available in the following variants:

Profile® Coreless Filter Element for Power & Utilities Applications:

The Profile Coreless Filters feature low differential pressure polypropylene, nylon, or polypropylene sulfide (PPS) medium, meaning fewer elements are required for a given flow rate. These filters are manufactured to a very high standard of quality assurance and cleanliness and in accordance with BS EN ISO 9001:2015.

The depth filter element offers –

Profile® Coreless Filter Element for Oil & Gas Applications:

Pall Profile Coreless Filter elements are ideal for gas filtration applications that involve removing very small-sized solid contaminants—typically in the micron and sub-micron size range. These gas filter elements are successfully used in several applications that demand efficient protection of critical downstream equipment and units. The filter element is built to a very high standard of quality assurance and cleanliness. The depth filter element complies with BS EN ISO 9001:2015 standards.

The Profile Coreless gas filter element –

Profile® Coreless Filter Element for Food & Beverage Applications:

These filters provide highly efficient clarification and particle filtration in high flow rate food and beverage applications. The filters come with melt-blown polypropylene media and are free of adhesives or surfactants. The Profile Coreless filters consist of a fixed fiber matrix with a graded pore structure. With the coarsest pore sizes in the cartridge’s outermost layers, the pore size decreases towards the innermost layers that facilitate pre-filtration and fine filtration within the same cartridge.

The depth filter element provides –

Pall’s Profile Coreless Filters have a wide range of applications across various industries.

Specs for Profile Coreless Filter Element for Power & Utilities Applications:

Materials of Construction

Filter Element: Polypropylene, Nylon, or Polyphenylene Sulphide (PPS)

Core Assembly: 316L Stainless Steel

Technical Information

Operating Characteristics in Compatible Fluids1

Maximum Differential Pressure |

Operating Temperature | ||

|---|---|---|---|

| Polypropylene | Nylon | Polypropylene Sulphide (PPS) |

|

| 4.0 bard (58 psid) | 32o C (89.6o F) | 32o C (89.6o F) | 32o C (89.6o F) |

| 1.0 bard (14.5 psid) | 82o C (179.6o F) | 130oC (266o F) | 204o C (400o F) |

Core Assembly Seals (removable options only)

Seal Material:

Ethylene Propylene Rubber (EPR)

Fluorocarbon Elastomer

FEP encapsulated Fluorocarbon Elastomer

Nitrile

1 Compatible fluids are defined as those that do not swell, soften, or attack any of the filter components

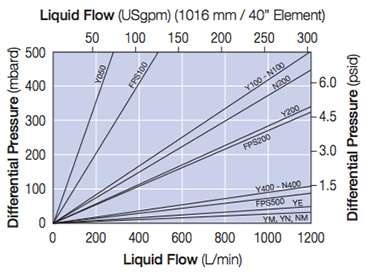

Flow Rates

* For clean water at ambient temperature for liquids of viscosity other than 1cP, multiply the ¢P by the viscosity in cP.

Specs for Profile Coreless Filter Element for Oil & Gas Applications:

Materials of Construction

Polypropylene or Polyphenylene Sulphide (PPS)

Operating Characteristics in Compatible Fluids*

Maximum Differential Pressure |

Operating Temperature | |

|---|---|---|

| Polypropylene | Polypropylene Sulphide (PPS) | |

| 4.0 bard (58 psid) | 32o C (89.6o F) | 32o C (89.6o F) |

| 1.0 bard (14.5 psid) | 82o C (179.6o F) | 204o C (400 oF) |

*Compatible fluids are defined as those which do not swell, soften, or attack any of the filter components.

Dimensions

| Nominal Length | 1016 mm (40 in) |

| Nominal Outside Diameter | 152 mm (6 in) |

| Nominal Inside Diameter | 114 mm (4.5 in) |

Performance

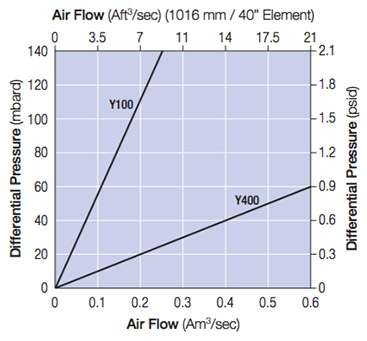

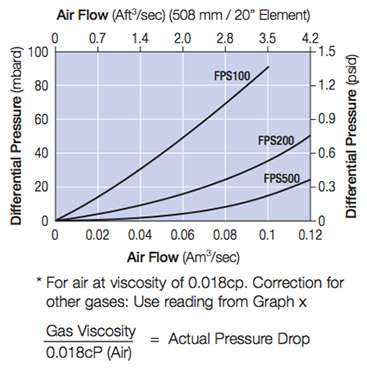

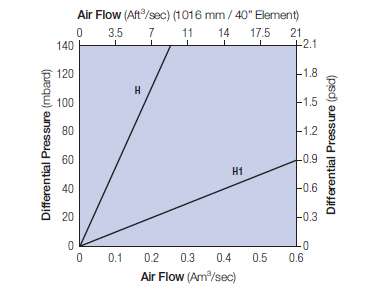

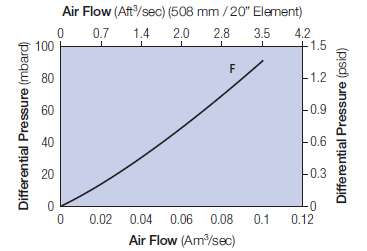

Flow Rates

Polypropylene Media

Polypropylene Sulphide Media

* For air at a viscosity of 0.018cp. Correction for other gases:

Use reading from Graph x = Gas Viscosity = Actual Pressure Drop

0.018cP (Air)

Specs for Profile Coreless Filter Element for Food & Beverage Applications

Materials of Construction

Filter Medium: Polypropylene

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific national legislation and/or regional regulatory requirements for food contact use.

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described, unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Operating Characteristics in Compatible Fluids1

| Maximum Differential Pressure2 | Operating Temperature |

|---|---|

| 4.0 bard (58 psid) | 32o C (90o F) |

| 1.0 bard (14.5 psid) | 82o C (180o F) |

1 Fluids that do not swell, soften, or adversely affect any of the filter components

2 In forward (out to in) flow direction

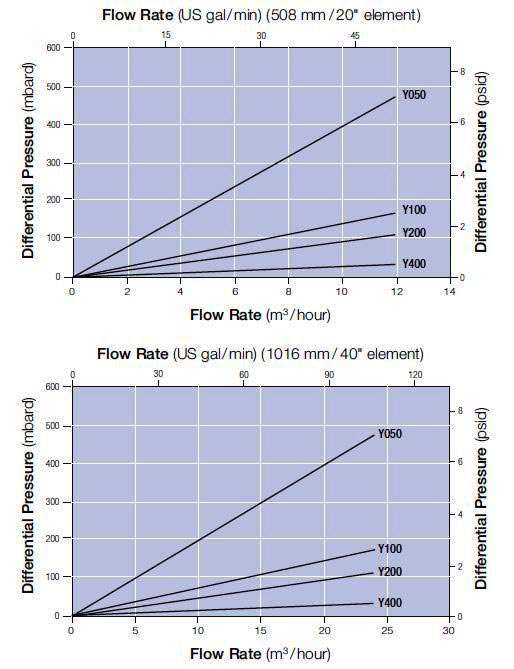

Typical Flow Rates3

3Typical initial clean delta p, for 508 mm (20”) and 1016 mm (40”) elements, water at 20o C (68o F). For assistance in filter assembly sizing, especially for fluids with a viscosity greater than 1 centipoise, contact your Pall representative.

Profile Coreless filters (1016 mm / 40”) are generally recommended for water flow rates up to 20 m3 / hour (88 US gal/min). Please contact your Pall representative for individual fluid applications and product options more suitable to higher flow rates.

Performance

Quality

Ordering Information for Profile Coreless Filter Element for Power & Utilities and Oil & Gas Applications:

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall. Refer to Pall for housing details.

Element Part Number: E60 [Table 1] [Table 2]

Core Assembly (removable option) Part Number: EHS60 [Table 1] [Table 3]

Table 1 : Nominal Length

| Code | Description |

|---|---|

| 2 | 508 mm (20”) |

| 4 | 1016 mm (40”) |

Table 2 : Media Options

| Polypropylene2 | Nylon2 | Polypropylene3 | Removal Rating in Liquids (µm) | Removal Rating in Gases at 0.3 µm4 |

|---|---|---|---|---|

| Sulphide (PPS) | ||||

| Y050 | - | - | 5 | - |

| Y100 | N100 | FPS100 | 10 | 99.997 % (Y100) 99.999 % (FPS100) |

| Y200 | N200 | FPS200 | 20 | - |

| Y400 | N400 | - | 40 | 99.995 % (Y400) |

| - | - | FPS500 | 50 | 99.869 % (FPS500) |

| YE5 | - | - | Coarse grade media for use in E-coat paint baths | |

| YM5 | NM | - | Coarse grade media for use in mica paint applications | |

| YN5 | - | - | Coarse grade media for use in mica paint applications | |

2 Beta 5000

3 Beta 1000 efficiency rating

4 Determined in laboratory trials using sodium chloride aerosols at 300 Sm3 / hr

5 Profile Coreless paint application filter elements are not given removal ratings.

Table 3: Core Assembly Seal Options

| Code | Description |

|---|---|

| J | Ethylene Propylene Rubber |

| HB | Fluorocarbon Elastomer |

| H1 | FEP encapsulated Fluorocarbon Elastomer |

| H13 | Nitrile |

Replacement Core Assembly Seals

| O-ring Seal | Part Number |

|---|---|

| Ethylene Propylene Rubber (EPR) | CA53418 and ORJPW-111P |

| Fluorocarbon Elastomer | LS00372 and LS00429 |

| FEP encapsulated Fluorocarbon Elastomer | CC62592 and CC62591 |

| Nitrile | LS0043 and LS543 |

For specific part numbers for oil & gas applications, please contact Pall.

Ordering Information for Profile Coreless Filter Element for Food & Beverage Applications:

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Element Part Number: E60 [Table 1] [Table 2] W

Example Part Number: E604Y400W

See bold reference code in tables.

Table 1 : Nominal Length

| Code | Description |

|---|---|

| 2 | 508 mm (20”) |

| 4 | 1016 mm (40”) |

Table 2: Removal Rating4

| Code | Rating (µm) at 99.98% efficiency (B-5000) |

|---|---|

| Y050 | 6 |

| Y100 | 10 |

| Y200 | 20 |

| Y400 | 40 |

4 Profile Coreless filter cartridge liquid retention ratings are based on a modified OSU-F2 single pass test in an aqueous medium.

Q. 1. What are the filter media options available for Profile Coreless Filters?

- The Profile Coreless Filters are available in the following media options –

While Profile Coreless Filters for Food and Beverage applications are available in polypropylene media, Profile Coreless Filters for Oil and Gas applications are available in polypropylene and polypropylene sulphide media. Profile Coreless Filters for Power and Utilities applications come with polypropylene, polypropylene sulphide (PPS), and Nylon media options.

Q. 2. How do Profile Coreless Filters help in cost savings?

- Profile Coreless Filters come with a large diameter cartridge and a continuous graded pore structure with proven depth technology. With their superior and consistent filtrate quality, long service life, these easy-to-fit filters have high flow rate capability and reduce operating costs. With less waste material, they help lower disposal costs as well.

Q.3. What are the ISO certificates of the related Manufacturing plants?

- The Coreless elements are produced in manufacturing sites with ISO 9001:2015 and ISO 14001:2015 certificates