Datasheets

Download:The PhotoKleen™ EZD-3XL filter is designed for smallvolume dispense systems to meet the requirements of advanced high through-put track systems. The PhotoKleen™ EZD-3XL filter has almost double the filter area (compared to the PhotoKleen™ EZD-3X filter), allowing for lower pressure drop during filtration. Two filter media – Asymmetric Nylon 6,6 and HDPE – are available. The naturally hydrophilic Nylon 6,6 membrane allows for spontaneous wettability, and offers lower defectivity on patterned wafers. The XP option is available for advanced lithography processes.

- Double the filter area compared to PhotoKleen™ EZD-3X filter capsule

- Easy change out capsule style filter assembly

- Two membrane material types available

- Minimized hold-up volume, and top in / top out flow direction

- Offers lower pressure drop for higher viscosity fluids

- Reduces tool down time by extending filter change-outs

- Offers suitable membranes for target applications

- Minimized organic extractables by XP option for rapid start-up and reducing chemical waste

- XP option guarantees low organic, metal and particle cleanliness for the most advanced processes.

Materials of Construction

| Components | Materials |

| Filter Media | P-Nylon : Hydrophilic Asymmetric Nylon 6,6 PE-Kleen: High Density Polyethylene (HDPE) |

| Support and Drainage | High Density Polyethylene (HDPE) |

| Core, Cage, and End Caps | High Density Polyethylene (HDPE) |

| Housing | High Density Polyethylene (HDPE) |

| O-ring | Perfluoroelastomer |

| Removal Ratings | P-Nylon : 2 nm, 5 nm, 10 nm, 20 nm, 40 nm PE-Kleen : 2 nm, 5 nm, 10 nm, 30 nm, 50 nm |

| Filter Area | P-Nylon : 2 nm: 3,200 cm2, 5 nm :2,100 cm2 10, 20, 40 nm : 2,500 cm2 PE-Kleen : 2, 5, 10, 30 nm : 2,800 cm2 50 nm : 2,900 cm2 |

| Maximum Forward Differential Pressure | P-Nylon : 0.27 MPa @ 20 °C / 39 psid @ 60 °F PE-Kleen : 0.29 MPa @ 30 °C / 42 psid @ 86 °F |

| Maximum Operating Temperature | 30 °C / 86 °F |

| Maximum Operating Pressure | 0.29 MPaG @ 30 °C / 42 psig @ 86 °F |

Dimensions 2

2 PhotoKleen™ EZD-3XL filter capsule requires PhotoKleen EZD-3XL head manifold

Typical Flow Characteristics - 1cP fluid, 20℃

PHD13 [1] EH11B3

Table 1

| Code | Filter Media | Removal Ratings | |

| XN2L4 | P-Nylon | Asymmetric 6,6 | 2 nm |

| HXN54 | Asymmetric Nylon6,6 | 5 nm | |

| AN01 | Asymmetric Nylon6,6 | 10 nm | |

| ANM | Asymmetric Nylon6,6 | 20 nm | |

| AND | Asymmetric Nylon6,6 | 40 nm | |

| UG2 | PE-Kleen | HDPE | 2 nm |

| UG5 | HDPE | 5nm | |

| UG001 | HDPE | 10 nm | |

| UG003 | HDPE | 30 nm | |

| UG005 | HDPE | 50 nm | |

3 For XP option add –XP to end of part number for below 10nm / 20nm removal ratings.

4 XP treatment is standard on 2nm / 5 nm removal rating.

Caution: For optimal filtration performance, it is recommended to replace your filters at-least once a year. Annual replacements will reduce the potential of any leakages that may result due to prolonged chemical exposure. Pall warrants its filters for a period of 1 year from the date of shipment.Specifications (Head Manifold)

Materials of Construction| Components | Materials |

| Head | PFA / HDPE |

| Fitting | PFA / PCTFE |

| Stage and lever | SUS304 |

| Adapter | SUS304 |

Connections

| Type | Inlet / Outlet | Vent |

| Flowell5 60 series | 1/4” (6.35 x 4.3 mm) Fitting | 4 x 3 mm Fitting |

| 5 x 3 mm Fitting | 5 x 3 mm Fitting | |

5 Flowell is a trademark of Flowell Co.,Ltd.

Part Numbers / Ordering Infomation (Head Manifold)

| Part Number | Inlet / Outlet | Vent |

| PHF13GFS44MWLTA | 1/4” (6.35 x 4.3 mm) Flowell 60 Fitting | 4 x 3 mm Flowell 60 Fitting |

| PHF13GFS55MLTA | 5 x 3 mm Flowell 60 Fitting | 5 x 3 mm Flowell 60 Fitting |

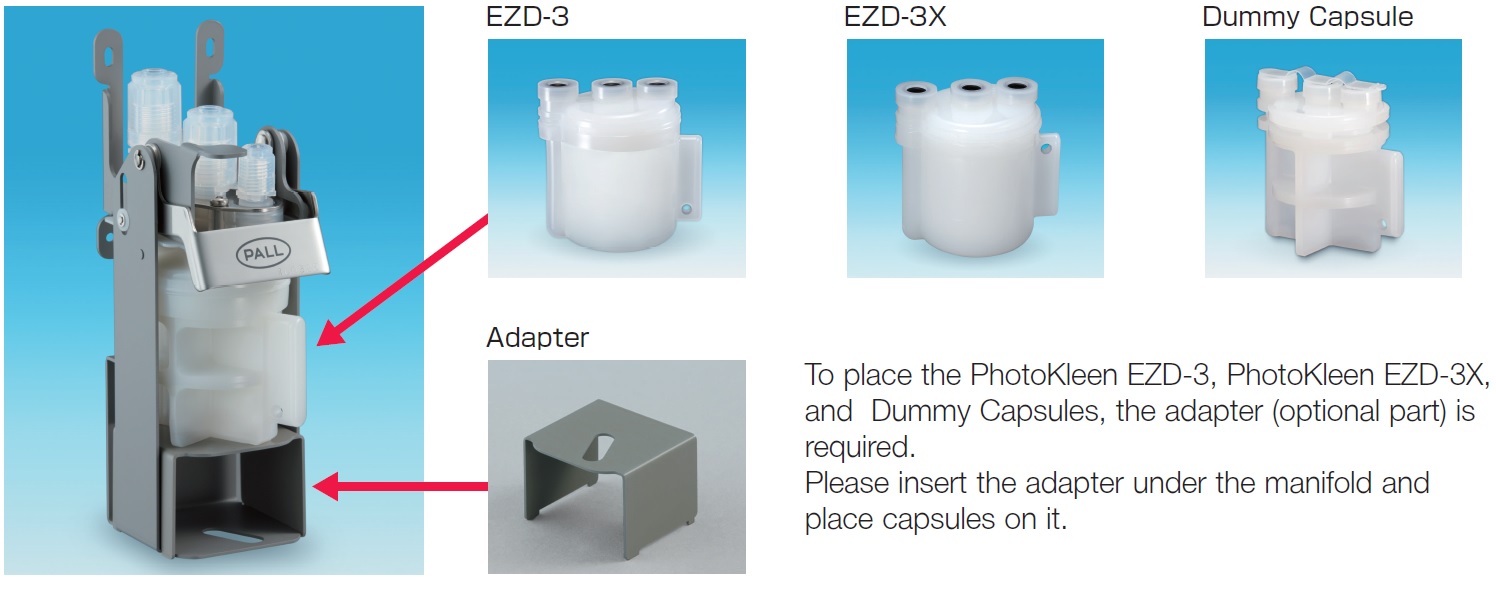

Optional Parts

| Product Name | Part Number | Notes |

| Adapter | PTH9101 | For the placement of other capsules |

| PhotoKleen EZD-3 | ||

| PhotoKleen EZD-3X | ||

| Dummy Capsules (PHDC12H11B, PHDC12H11B-XP+) | ||

| Dummy Capsule | PHDC12H11B | O-ring : Perfluoroelastomer |

| PHDC12H11B-XP+ | O-ring : Perfluoroelastomer, Special Clean Product | |

Dimensions

We appreciate your review of this product. Please login to your account to leave a review.