Materials of Construction

| Filter Medium Type |

Filter Medium |

Support/Drainage Materials |

End Caps |

Wrap Materials |

| HDC® II Medium |

High Area Polypropylene Structure |

Polypropylene |

Glass Filled Polypropylene |

Polypropylene and Polyolefin Hotmelt |

| Profile® Medium in Ultipleat Format |

Pleated Polypropylene Depth Structure |

Polypropylene |

Glass Filled Polypropylene |

Polypropylene |

| Ultipor® GF Medium |

Resin Bonded Glass Fiber / Polyester Support |

Polyester / Nylon |

Glass Filled Acetal |

Polypropylene and Polyolefin Hotmelt |

| Ultipleat HT Medium |

Glass Fiber Media with Aramid Support |

Craneglass/Polybutylene Terephthalate |

Acetal |

Aramid |

| Ultipleat CAS Medium |

Pleated Polypropylene / Polyether Sulfone Membrane |

Polypropylene |

Glass Filled Polypropylene |

Polypropylene |

Operating Conditions1

Maximum Differential Pressure2

(normal inside to outside flow)

For Polypropylene Medium/ CAS Composite Medium: 3.4 bard at 82°C/ 50 psid at 180°F

For Glass Fiber Medium: 3.4 bard at 121°C/ 50 psid at 250°F

1) Maximum temperature in aqueous systems is 60°C / 140°F for GF medium.

2) For fluids compatible with the filter element at the stated temperature.

Removal Rating3 Options:

2.0 µm4, 4.5 µm, 10 µm, 20 µm,

40 µm, 70 µm, 100 µm

3 The test procedure used is an adaptation of ISO 4572, modified to determine the micron size above which particles are quantitatively removed.

4 2 microns at 99% efficiency.

Specs for Ultipleat® High Flow 1 Micron Element:

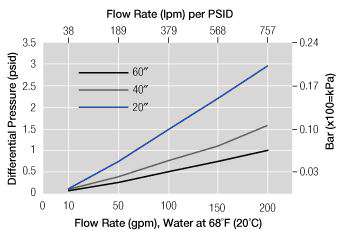

Performance Specifications

Water flow rate

20" length ® 68 gpm/psid (257 lpm/70 mbar)

40" length ® 135 gpm/psid (511 lpm/70 mbar)

60" length ® 204 gpm/psid (772 lpm/70 mbar)

Maximum forward differential pressure

50 psid @ 180®F (3.44 bar @ 82®C)

Maximum operating temperature

180®F (82®C)

Sanitization ®

- Can be sanitized with hot water (185®-194®F/85®-90®C) for a maximum of 100 cycles®(1 cycle = 10 minutes) without compromising the removal efficiency of the filter.

- Peracetic acid, chlorinated alkaline products, and other sanitization chemicals may be used.® Contact Pall for recommended procedures.

Product Specifications

Materials of Construction

Filter Media:® ®1 ®m polyethersulfone (PES)

Outer Sleeve and End Caps:® ®Polypropylene

Drainage and Wrap:® ®Polypropylene

Wrap Adhesive: ®Polyolefin hot melt

Filter Seal: ®FDA compliant ethylene propylene

Dimensions

Diameter: 6.3" (16 cm)®

Length: 20", 40", 60"®(51 cm, 102 cm, 152 cm)

Other Ultipleat High Flow Elements

Ultipleat High Flow elements are available in other filter® media with absolute ratings of 2, 4.5, 10, 20, 40, and 100 ®m. Contact Pall for more information.

PERFORMANCE

1 ®m Ultipleat High Flow

Ultipleat® High Flow Filter Elements (1 µm) for Water Polishing Filtration:

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Ultipleat Filter Element Declaration of Compliance

Materials of Construction

- Filter Medium: Pre-filtration layer Pall proprietary melt-blown polypropylene media, Final filtration layer Pall proprietary Supor® PES membrane (polyethersulfone)

- Support Mesh and Outer Wrap: Polypropylene

- End Caps and Handle: Polypropylene (10% glass fiber reinforced)

- O-ring Seal: Ethylene propylene rubber

Operating Characteristics in Compatible Fluids2

| Maximum Differential Pressure |

Max. Operating Temperature3 |

| 3.45 bard (50 psid) (forward direction) |

82 °C (180 °F) |

Sanitization4

| Method |

Temperature |

Cumulative Time |

| Hot Water |

85-90 °C (185-194 °F) |

10 hours |

| 320 ppm total peroxides |

20 °C (68 °F) |

|

2Compatible fluids are defined as those that do not swell, soften, or attack any filter components.

3Not recommended where the temperature is cycled more than 10 °C (50 °F).

4Measured under laboratory test conditions. Users should verify suitability against their own conditions of use. Where indicated 10-minute sanitization cycles were utilized.

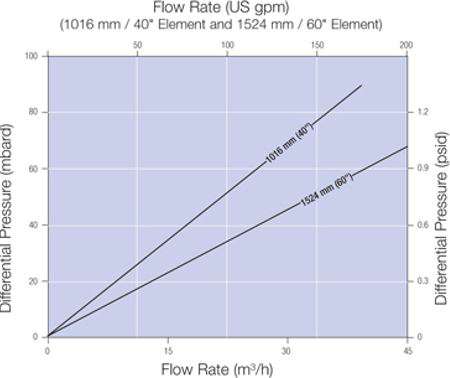

5Typical initial clean media differential pressure (Δp) per 1016 mm (40 in.) and 1524 mm (60 in.) cartridge for water at 20 °C (68 °F); viscosity 1 centipoise. For assistance in filter assembly sizing and housing selection, contact your Pall representative.

PERFORMANCE

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

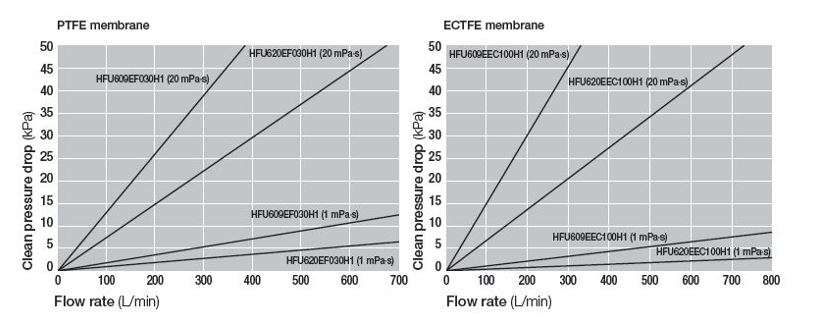

Specs for Ultipleat® High Flow Filter for Etchant Applications:

| Components |

Materials |

| Filter Medium |

PTFE |

ECTFE |

| Removal Rating |

3 µm |

10 µm |

| Support, drainage |

Polypropylene |

ECTFE |

| Support core |

Polypropylene |

ECTFE |

| End caps |

Polypropylene (glass fiber filled) |

|

| O-ring |

FEP encapsulated fluoroelastomer |

|

| Maximum Operating Temperature |

82 ˚C / 180 ˚F |

|

| Maximum forward differential pressure |

0.34 MPa @ / 50 ˚C 50 psi @ 122 ˚F |

|

Pressure Drop vs. Liquid Flow Rate1

1 For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Since etchants can vary significantly, it is recommended that the filter be tested for compatibility at the service temperature to ensure long service life.