Order Products

Filter Grade

4.5 µm

Ultipleat® High Flow Element, HFU660UY045JUW

1/EA

1

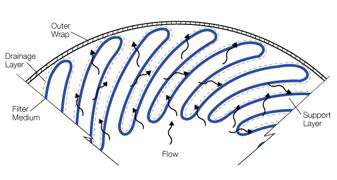

The Ultipleat® High Flow Filter is a large diameter, coreless, single open-ended, pleated cartridge with an inside-to-outside flow pattern. Its unique crescent-shaped pleat geometry, along with its large 152.4 mm (6 inch) diameter and proprietary range of available Pall filter media, permits you to use significantly fewer filters and smaller housings for high flow rate applications. Systems can handle up to 115,443 lpm (30,500 gpm).

Filter Grade

4.5 µm

Features and Benefits:

High flow rate per filter cartridge

These pleated high flow filters are available in the following variants –

Ultipleat® High Flow 1 Micron Element:

With its large 6.3 inch (16 cm) diameter, this filter allows you to use fewer filters to remove fine particles and cysts in high flow applications.

*Particle removal rating

Crescent-Shaped Pleat Geometry

Ultipleat® High Flow Filter Elements (1 µm) for Water Polishing Filtration:

These filter elements make use of polyethersulfone (PES) media with unique, laid-over pleat geometry. The filter's unique laid-over pleat geometry, combined with its large diameter, requires fewer elements for a given flow rate than standard diameter cartridges. Therefore, filter vessels are smaller, resulting in lower capital, installation costs, and reduced operating costs.

Ultipleat® High Flow Filter for Etchant Applications:

This filter is designed for TFT LCD liquid applications like wet etching and cleaning. The filter’s large diameter, inside-out flow path, and unique, high area, and pleated construction provide long service life. The filter is more economical due to its high flow capacity.

Please note that the service life is dependent upon chemical compatibility and temperature.

Ultipleat® High Flow Filter Elements with Profile® UP Media:

These pleated high flow filters are designed to withstand high flow rates up to 113 m3/hour (500 US gal/min) in a single 1524 mm (60 inch) cartridge. By utilizing Profile UP media with unique, laid-over pleat geometry, and a large diameter, fewer elements are required for a given flow rate than standard diameter cartridges. The filters feature a fixed fiber matrix and are free from surfactants and adhesives.

Ultipleat® High Flow XL Filters:

The spacing between the pleats within the Ultipleat XL filter has been optimized to deal with applications with moderate solids loadings.

Pall also offers Ultipleat® High Flow Housings for different applications in various industries.

Pall’s Ultipleat High Flow Filters have a wide range of applications across various industries.

Materials of Construction

| Filter Medium Type | Filter Medium | Support/Drainage Materials | End Caps | Wrap Materials |

|---|---|---|---|---|

| HDC® II Medium | High Area Polypropylene Structure | Polypropylene | Glass Filled Polypropylene | Polypropylene and Polyolefin Hotmelt |

| Profile® Medium in Ultipleat Format | Pleated Polypropylene Depth Structure | Polypropylene | Glass Filled Polypropylene | Polypropylene |

| Ultipor® GF Medium | Resin Bonded Glass Fiber / Polyester Support | Polyester / Nylon | Glass Filled Acetal | Polypropylene and Polyolefin Hotmelt |

| Ultipleat HT Medium | Glass Fiber Media with Aramid Support | Craneglass/Polybutylene Terephthalate | Acetal | Aramid |

| Ultipleat CAS Medium | Pleated Polypropylene / Polyether Sulfone Membrane | Polypropylene | Glass Filled Polypropylene | Polypropylene |

Operating Conditions1

Maximum Differential Pressure2

(normal inside to outside flow)

For Polypropylene Medium/ CAS Composite Medium: 3.4 bard at 82°C/ 50 psid at 180°F

For Glass Fiber Medium: 3.4 bard at 121°C/ 50 psid at 250°F

1) Maximum temperature in aqueous systems is 60°C / 140°F for GF medium.

2) For fluids compatible with the filter element at the stated temperature.

Removal Rating3 Options:

2.0 µm4, 4.5 µm, 10 µm, 20 µm,

40 µm, 70 µm, 100 µm

3 The test procedure used is an adaptation of ISO 4572, modified to determine the micron size above which particles are quantitatively removed.

4 2 microns at 99% efficiency.

Specs for Ultipleat® High Flow 1 Micron Element:

Performance Specifications

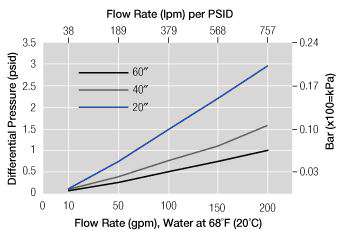

Water flow rate

20" length ® 68 gpm/psid (257 lpm/70 mbar)

40" length ® 135 gpm/psid (511 lpm/70 mbar)

60" length ® 204 gpm/psid (772 lpm/70 mbar)

Maximum forward differential pressure

50 psid @ 180®F (3.44 bar @ 82®C)

Maximum operating temperature

180®F (82®C)

Sanitization ®

Product Specifications

Materials of Construction

Filter Media:® ®1 ®m polyethersulfone (PES)

Outer Sleeve and End Caps:® ®Polypropylene

Drainage and Wrap:® ®Polypropylene

Wrap Adhesive: ®Polyolefin hot melt

Filter Seal: ®FDA compliant ethylene propylene

Dimensions

Diameter: 6.3" (16 cm)®

Length: 20", 40", 60"®(51 cm, 102 cm, 152 cm)

Other Ultipleat High Flow Elements

Ultipleat High Flow elements are available in other filter® media with absolute ratings of 2, 4.5, 10, 20, 40, and 100 ®m. Contact Pall for more information.

PERFORMANCE

1 ®m Ultipleat High Flow

Ultipleat® High Flow Filter Elements (1 µm) for Water Polishing Filtration:

Food Contact Compliance

Materials of Construction

Operating Characteristics in Compatible Fluids2

| Maximum Differential Pressure | Max. Operating Temperature3 |

|---|---|

| 3.45 bard (50 psid) (forward direction) | 82 °C (180 °F) |

Sanitization4

| Method | Temperature | Cumulative Time |

|---|---|---|

| Hot Water | 85-90 °C (185-194 °F) | 10 hours |

| 320 ppm total peroxides | 20 °C (68 °F) |

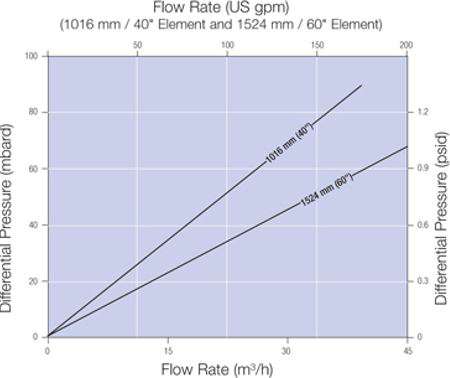

Typical Flow Rates5

2Compatible fluids are defined as those that do not swell, soften, or attack any filter components.

3Not recommended where the temperature is cycled more than 10 °C (50 °F).

4Measured under laboratory test conditions. Users should verify suitability against their own conditions of use. Where indicated 10-minute sanitization cycles were utilized.

5Typical initial clean media differential pressure (Δp) per 1016 mm (40 in.) and 1524 mm (60 in.) cartridge for water at 20 °C (68 °F); viscosity 1 centipoise. For assistance in filter assembly sizing and housing selection, contact your Pall representative.

PERFORMANCE

Quality

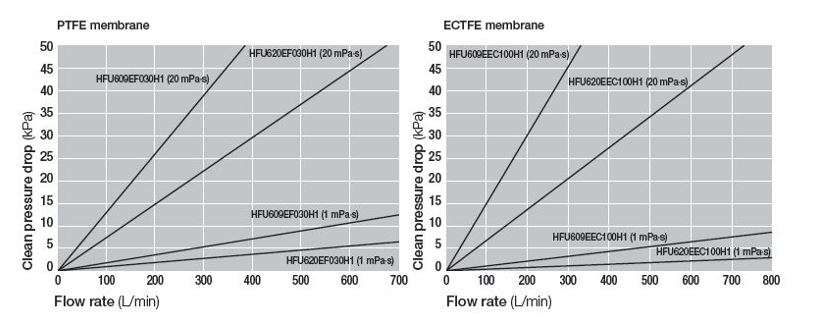

Specs for Ultipleat® High Flow Filter for Etchant Applications:

| Components | Materials | |

|---|---|---|

| Filter Medium | PTFE | ECTFE |

| Removal Rating | 3 µm | 10 µm |

| Support, drainage | Polypropylene | ECTFE |

| Support core | Polypropylene | ECTFE |

| End caps | Polypropylene (glass fiber filled) |

|

| O-ring | FEP encapsulated fluoroelastomer |

|

| Maximum Operating Temperature | 82 ˚C / 180 ˚F | |

| Maximum forward differential pressure | 0.34 MPa @ / 50 ˚C 50 psi @ 122 ˚F |

|

Pressure Drop vs. Liquid Flow Rate1

1 For liquids with viscosity differing from water, multiply the pressure drop by the viscosity in centipoise.

Since etchants can vary significantly, it is recommended that the filter be tested for compatibility at the service temperature to ensure long service life.

Filter Cartridge Part Number: HFU Table [1] [2] [3]

Table 1:

| Code | Filter Dimensions, (nominal) Diameter (in. / mm) x Length (in. / mm) | Suggested Maximum Water Flow Per Cartridge- US gpm / L/min / MGD |

|---|---|---|

| 620 | 6 / 152.4 x 20 / 508 | 175 / 663 / 0.25 |

| 640 | 6 / 152.4 x 40 / 1016 | 350 / 1325 / 0.5 |

| 660 | 6 / 152.4 x 60 / 1524 | 500 / 1900 / 0.7 |

| 680 | 6 / 152.4 x 80 / 2032 | 500 / 1900 / 0.7 |

Table 2:

| Code-Filter O-Ring | Material |

|---|---|

| H13 (Standard for glass fiber and aramid fiber filters) | Nitrile |

| H13U3 | Nitrile U-Cup |

| J (Standard for polypropylene filters) | Ethylene Propylene |

| JU3 | Ethylene Propylene U-Cup |

| H4 | Silicone |

| H | Fluoroelastomer |

3 U-Cup seal is standard for the 1-micron composite filter.

Table 3:

Filter Cartridge Pressure Drop (typical) per Filter Length Shown4

| Medium Type | Grade | Absolute Liquid Removal Rating (microns) at 99.98% by particle count5 | 508 mm / 20 inch length | 1016 mm / 40 inch length | ||

|---|---|---|---|---|---|---|

| psid/100gpm | mbar/M3/hr | psid/100gpm | mbar/M3/hr | |||

| HDC II Medium | J060 | 6 | 0.158 | 0.48 | 0.08 | 0.24 |

| J100 | 10 | 0.12 | 0.36 | 0.06 | 0.18 | |

| J200 | 20 | 0.1 | 0.3 | 0.05 | 0.15 | |

| Profile Medium in Ultipleat Format | UY0206 | 2 | 1.091 | 3.31 | 0.54 | 1.64 |

| UY045 | 4.5 | 0.489 | 1.48 | 0.242 | 0.73 | |

| UY060 | 6 | 0.395 | 1.2 | 0.196 | 0.59 | |

| UY100 | 10 | 0.344 | 1.04 | 0.17 | 0.52 | |

| UY200 | 20 | 0.243 | 0.74 | 0.12 | 0.36 | |

| UY4007 | 40 | 0.182 | 0.55 | 0.09 | 0.27 | |

| UY7007 | 70 | 0.04 | 0.12 | 0.02 | 0.06 | |

| UY10007 | 90 | 0.027 | 0.08 | 0.013 | 0.04 | |

| Ultipor GF Medium | GF020 | 2 | 0.219 | 0.66 | 0.11 | 0.33 |

| GF060 | 6 | 0.18 | 0.55 | 0.09 | 0.27 | |

| GF100 | 10 | 0.159 | 0.48 | 0.08 | 0.24 | |

| GF200 | 20 | 0.119 | 0.36 | 0.06 | 0.18 | |

| GF4007 | 29 | 0.1 | 0.3 | 0.05 | 0.15 | |

| Ultipleat CAS Medium | CAS010 | 1 | 1.496 | 4.54 | 0.74 | 2.25 |

| Medium Type | Grade | Absolute Liquid Removal Rating (microns) at 99.98% by particle count5 | 508 mm / 20 inch length | 1016 mm / 40 inch length | 1524 mm / 60 inch length | 2032 mm / 80 inch length | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| psid/100 gpm | mbar/M3/hr | psid/100gpm | mbar/M3/hr | psid/100 gpm | mbar/M3/hr | psid/100 gpm | mbar/M3/hr | |||

| HDC II Medium | J060 | 6 | 0.158 | 0.4800 | 0.080 | 0.24 | 0.058 | 0.170 | 0.040 | 0.12 |

| J100 | 10 | 0.12 | 0.3600 | 0.060 | 0.18 | 0.04 | 0.120 | 0.030 | 0.09 | |

| J200 | 20 | 0.1 | 0.3000 | 0.050 | 0.15 | 0.033 | 0.100 | 0.025 | 0.08 | |

| Profile Medium in Ultipleat Format | UY0206 | 2 | 1.091 | 3.3100 | 0.540 | 1.64 | 0.362 | 1.100 | 0.270 | 0.82 |

| UY045 | 4.5 | 0.489 | 1.4800 | 0.242 | 0.73 | 0.162 | 0.490 | 0.121 | 0.37 | |

| UY060 | 6 | 0.395 | 1.2000 | 0.196 | 0.59 | 0.131 | 0.400 | 0.098 | 0.30 | |

| UY100 | 10 | 0.344 | 1.0400 | 0.170 | 0.52 | 0.114 | 0.350 | 0.085 | 0.26 | |

| UY200 | 20 | 0.243 | 0.7400 | 0.120 | 0.36 | 0.08 | 0.240 | 0.060 | 0.18 | |

| UY4007 | 40 | 0.182 | 0.5500 | 0.090 | 0.27 | 0.06 | 0.180 | 0.045 | 0.14 | |

| UY7007 | 70 | 0.04 | 0.1200 | 0.020 | 0.06 | 0.013 | 0.040 | 0.010 | 0.03 | |

| UY10007 | 90 | 0.027 | 0.0800 | 0.013 | 0.04 | 0.009 | 0.030 | 0.007 | 0.02 | |

| Ultipor GF Medium | GF020 | 2 | 0.219 | 0.6600 | 0.110 | 0.33 | 0.073 | 0.220 | 0.055 | 0.17 |

| GF060 | 6 | 0.18 | 0.5500 | 0.090 | 0.27 | 0.06 | 0.180 | 0.045 | 0.14 | |

| GF100 | 10 | 0.159 | 0.4800 | 0.080 | 0.24 | 0.053 | 0.160 | 0.040 | 0.12 | |

| GF200 | 20 | 0.119 | 0.3600 | 0.060 | 0.18 | 0.04 | 0.120 | 0.030 | 0.09 | |

| GF4007 | 29 | 0.1 | 0.3000 | 0.050 | 0.15 | 0.033 | 0.100 | 0.025 | 0.08 | |

| HT Medium | HT060 | 6 | 0.13 | 0.400 | 0.097 | 0.30 | ||||

| Ultipor® GF Medium-XL | HGF100 | 10 | 0.0029 | 0.8800 | 0.001 | 0.425 | 0.001 | 0.304 | ||

| Ultipleat CAS Medium | CAS010 | 1 | 1.496 | 4.5400 | 0.740 | 2.25 | 0.496 | 1.510 | 0.370 | 1.12 |

4 Multiply this value by the total system flow to determine the aqueous pressure drop. For fluids other than water, multiply this value by the fluid’s viscosity at the operating temperature in centipoise. This value is the pressure drop across the Ultipleat High Flow filter(s) only; it must be added to the pressure drop contribution from the Ultipleat High Flow filter housing.

5 The test procedure used is an adaptation of ISO 4572, modified to determine the micron size above which particles are quantitatively removed.

6 2 microns at 99% efficiency.

7 Precision evaluation of the 99.98% removal efficiency for these coarse grades is not possible with the ISO modified test procedure utilized. The removal efficiency was determined by the maximum spherical particle analysis.

Ordering information for Ultipleat® High Flow Filter For Etchant Applications

PTFE membrane

HFU6 Table [1] EF030H1

ECTFE membrane

HFU6 Table [1] EEC100H1

| Code | Length |

|---|---|

| O9 | 249 mm / 9.8 in |

| 20 | 526 mm / 20.7 in |

Q. 1. What are the filter grade ratings available for Ultipleat High Flow Filters?

- These pleated high flow filters are available in filter grade options ranging from 1 µm to 100 µm.

Q. 2. What are the filter medium options available for Ultipleat High Flow Filters?

- The Ultipleat high flow filters are available in the following media options –